Catalogus

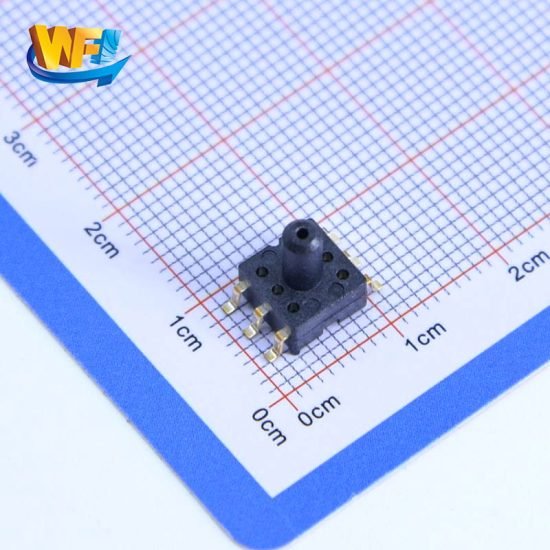

In modern industrial automation and precision measurement applications, pressure sensor range and accuracy directly impact system performance. The WF100E series achieves continuous measurement capability from negative to positive pressure through innovative wide-range technology.

1. Core Advantages of Wide-Range Technology

1.1 Technical Principles and Structural Design

WF100E wide-range technology is based on silicon-based MEMS-manufactured piezoresistive sensing elements, achieving bidirectional pressure measurement through precise diaphragm structural design. The sensor employs a Wheatstone bridge configuration internally, where resistance values change accordingly when the diaphragm experiences positive or negative pressure, producing electrical signals proportional to pressure.

1.2 Range and Accuracy Performance

The WF100E wide-range version supports ±100KPa measurement range, covering applications from vacuum to moderate pressure requirements. Its linearity reaches 0.25%FSO with temperature compensation range of -40°C to +125°C, ensuring stable measurement performance in harsh environments.

1.3 Power Adaptability and Consumption Optimization

The sensor supports both 3V and 5V power supply, adapting to different system power configurations. Low power consumption design makes it excellent for battery-powered portable devices, with static current consumption of only 1.5mA and dynamic response time less than 3ms.

2. Practical Value of Positive Pressure Measurement

2.1 Positive Pressure Definition and Measurement Principles

Positive pressure refers to pressure states higher than standard atmospheric pressure. In the WF100E series, the P model is specifically optimized for 0~100KPa positive pressure range. Positive pressure measurement is widely used in gas pipeline monitoring and liquid transport system pressure control scenarios.

2.2 Critical Role in Industrial Applications

In industrial automation systems, positive pressure measurement is crucial for ensuring safe system operation. WF100E’s positive pressure measurement capability can monitor pipeline pressure, tank pressure, and various pressurization equipment working conditions in real-time.

3. Technical Characteristics of Negative Pressure Measurement

3.1 Negative Pressure Concept and Measurement Challenges

Negative pressure refers to pressure states lower than standard atmospheric pressure. The WF100E N model is specifically designed for -100KPa~0 range negative pressure measurement. Negative pressure measurement is technically more challenging as it requires processing weak signal changes in vacuum environments.

3.2 Vacuum Applications and Precision Control

Negative pressure measurement plays a key role in vacuum packaging, medical devices, and semiconductor manufacturing. WF100E’s negative pressure measurement capability enables monitoring of vacuum pump extraction efficiency, vacuum chamber sealing performance, and various vacuum process controls.

4. Technical Integration and System Compatibility

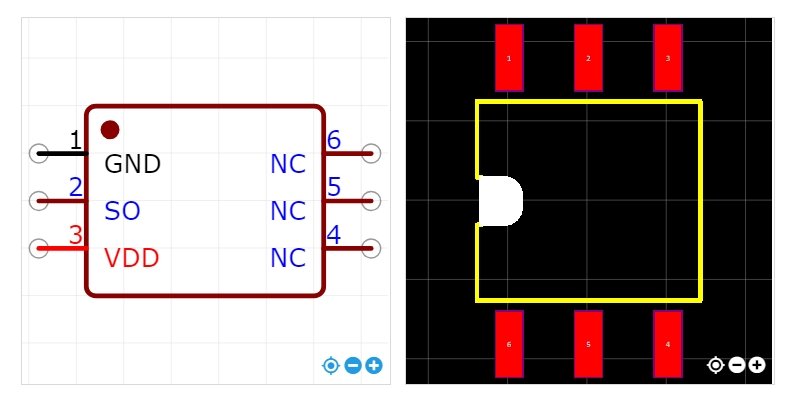

4.1 Signal Processing and Data Output

WF100E uses analog voltage output with signals proportional to supply voltage, facilitating integration with various data acquisition systems. The sensor integrates temperature compensation and signal conditioning circuits internally, ensuring output signal stability and accuracy.

4.2 Environmental Adaptability and Reliability

The sensor combines stainless steel diaphragm with plastic encapsulation, providing excellent corrosion resistance and environmental adaptability. IP65 protection rating ensures reliable operation in humid, dusty environments.

5. Temperature Compensation and Analog Output Technology

5.1 Temperature Compensation Principles and Implementation

WF100E series integrates advanced temperature compensation technology, utilizing built-in temperature sensors to monitor environmental temperature changes and automatically adjust output signals to eliminate temperature effects. The compensation algorithm uses polynomial curve fitting technology, maintaining 0.02%FSO/°C temperature coefficient across -40°C to +125°C range.

5.2 Analog Output Characteristics and Signal Processing

The sensor features proportional analog output design with 0.5V to 4.5V output voltage range, linearly related to supply voltage. Output impedance below 10kΩ provides strong driving capability, directly connecting to ADC or instrumentation amplifiers. Signal output offers excellent linearity and low noise characteristics with >60dB signal-to-noise ratio.

5.3 Output Calibration and Precision Optimization

WF100E undergoes rigorous temperature cycling tests and multi-point calibration before factory delivery, ensuring consistent output characteristics. Users can perform field calibration through simple two-point calibration methods to achieve higher measurement accuracy. The sensor supports independent zero point and full-scale adjustment.

6. Application Selection and Technical Recommendations

6.1 Model Selection Strategy

Engineers should determine appropriate models based on specific application requirements when selecting WF100E series. Wide-range models suit dynamic systems requiring bidirectional pressure monitoring, positive pressure models suit unidirectional pressurization systems, and negative pressure models suit vacuum-related applications.

6.2 Installation and Calibration Requirements

To ensure measurement accuracy, sensor installation should avoid mechanical stress and temperature gradient effects. Multi-point calibration during system commissioning is recommended, particularly under extreme working temperature conditions.

Conclusie

The WF100E series MEMS pressure sensors successfully achieve unified positive and negative pressure measurement solutions through innovative wide-range technology design. The three configuration options provide engineers with flexible choices, meeting precise measurement requirements across different application scenarios, enhanced by advanced temperature compensation and stable analog output performance.

De bovenstaande introductie schetst slechts het oppervlak van de toepassingen van druksensortechnologie. We zullen doorgaan met het verkennen van de verschillende soorten sensorelementen die in verschillende producten worden gebruikt, hoe ze werken en hun voor- en nadelen. Als u meer informatie wilt over wat hier wordt besproken, kunt u de gerelateerde inhoud verderop in deze handleiding bekijken. Als u weinig tijd heeft, kunt u ook hier klikken om de details van deze handleidingen te downloaden Luchtdruksensorproduct PDF -gegevens.

Voor meer informatie over andere sensortechnologieën kunt u terecht Bezoek onze sensorenpagina.