Conventional piezoresistive sensors often need external circuits or complex algorithms to correct for temperature changes, which raises power use and system cost. Here we take a structure-driven approach to temperature compensation: local island mass, curved crossed beams and an octagonal curved sensing membrane work together so that electrostatic feedback and mechanical stress redistribution give passive temperature compensation. The aim is to present engineers and decision-makers with a solution that’s manufacturable, integrable and outperforms traditional compensation routes.

Catalogus

1. Design and structural innovation

Island-beam-membrane coupling structure

The island-beam-membrane coupling arranges small local “islands” on the sensing membrane and pairs them with curved crossed beams to shape the stress field in a controlled way. As temperature rises the islands produce minute thermal expansions that interact with a designed electrostatic feedback path to partly cancel the membrane’s thermally induced output errors. The octagonal curved sensing membrane increases stress concentration and improves linearity, so the device reaches roughly 10 mV/FS on a 5 V supply while keeping good mechanical strength and fatigue life.

2. Temperature-self-compensation mechanism and performance data

Passive compensation and key metrics

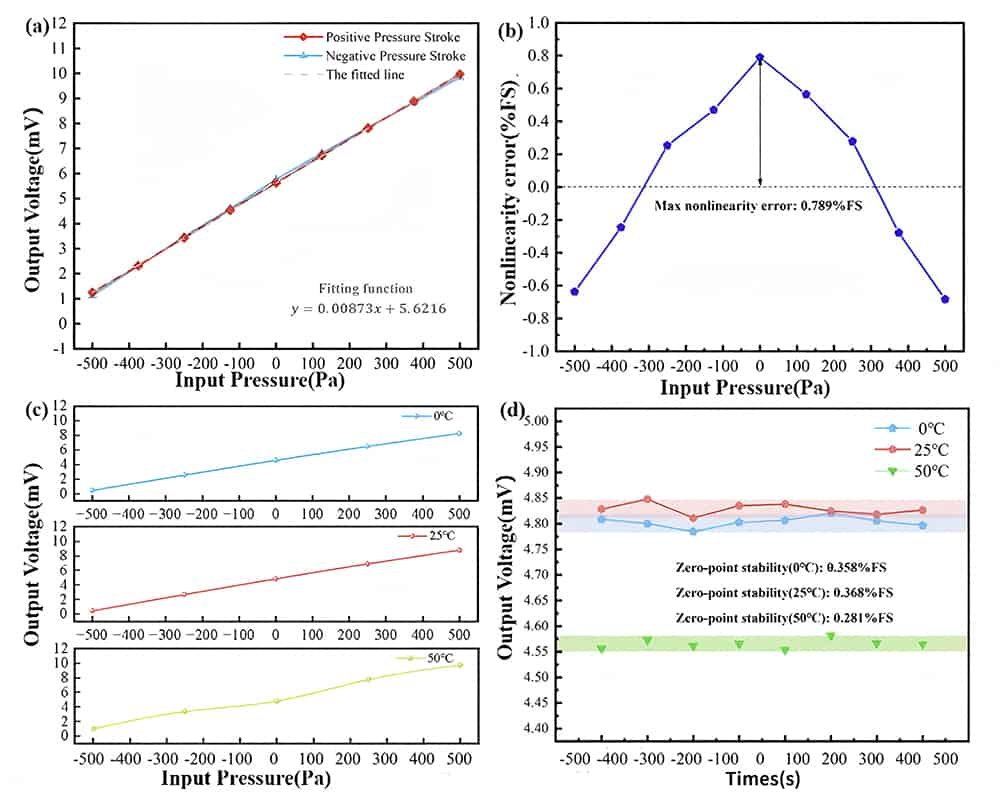

Passive compensation depends on geometry and elastic coupling: temperature shifts cause relative motion between island and beam, changing the stress distribution and, via the electrostatic feedback route, offsetting zero-point drift. Measured over 0°C to 50°C the zero-point drift is 0.081%FS, full-range drift 0.090%FS, nonlinearity 0.307%FS and repeatability 0.265%FS — industrial-grade performance that avoids extra circuitry, higher power draw or complex algorithms.

3. Process and consistency control

SOI and dual-DRIE for machining precision

We use SOI processing and double-sided deep reactive-ion etching (DRIE) to tightly control island and membrane thicknesses, reaching manufacturing consistency up to 99.78%. This process mix keeps microstructure dimensions stable while cutting residual stress and batch variation, delivering zero-point stability under 0.4% and supporting volume production and reliability validation.

4. Test methods and result analysis

Temperature cycling and output evaluation

Under pressure cycles from −500 Pa to 500 Pa we tested the sensor at different temperatures (0°C, 25°C, 50°C), recording zero-point drift over time and nonlinearity curves. At room temperature the output is highly linear; under temperature changes both zero-point and full-range drift are much better than conventional circuit-based compensation, showing that the structural self-compensation is reliable and stable under dynamic thermal conditions.

5. System integration and engineering considerations

Packaging, interfaces and low-power integration

The photographed part is an SMD package with a metal pressure port and four solder pads for board-mounting. When integrating, pay attention to port sealing, welding stress affecting zero-point, and matching the downstream ADC input range and reference to the ~10 mV/FS scale. Since the structure provides temperature compensation, external temperature-compensation circuitry can be minimised, lowering system power and BOM cost.

Conclusie

The island-beam-membrane coupling structure achieves temperature self-compensation, reducing reliance on external circuits or heavy algorithms.

Over 0–50°C performance: zero-point drift 0.081%FS, full-range drift 0.090%FS, nonlinearity 0.307%FS, repeatability 0.265%FS.

SOI + dual-DRIE process yields 99.78% consistency and zero-point stability <0.4%.

Structural self-compensation delivers lower power draw and higher integration, easing use in high-precision applications.

Engineering attention to packaging and electrical matching reduces integration risk and preserves measurement accuracy.

De bovenstaande introductie schetst slechts het oppervlak van de toepassingen van druksensortechnologie. We zullen doorgaan met het verkennen van de verschillende soorten sensorelementen die in verschillende producten worden gebruikt, hoe ze werken en hun voor- en nadelen. Als u meer informatie wilt over wat hier wordt besproken, kunt u de gerelateerde inhoud verderop in deze handleiding bekijken. Als u weinig tijd heeft, kunt u ook hier klikken om de details van deze handleidingen te downloaden Luchtdruksensorproduct PDF -gegevens.

Voor meer informatie over andere sensortechnologieën kunt u terecht Bezoek onze sensorenpagina.