Catalogus

Ceramic pressure sensors serve as the core components of modern fluid pressure monitoring systems, providing high-precision and durable measurement solutions for engineers and technical decision-makers through their unique ceramic diaphragm structure and thin-film deposition technology. These resistive MEMS sensors feature miniaturized design, low noise characteristics, and built-in temperature compensation, capable of accurately sensing pressure applied by gases or liquids within a 7Bar measurement range. The chemical stability and thermal shock resistance of ceramic materials make them ideal alternatives to traditional silicon-based sensors, particularly suitable for medical-grade applications and pressure monitoring in harsh environments.

1. Technical Principles and Construction of Ceramic Pressure Sensors

Ceramic Diaphragm Core Technology

Ceramic pressure sensors employ advanced ceramic diaphragms as pressure-sensing elements, offering significant advantages over traditional silicon-based materials. The ceramic diaphragm is formed through thin-film deposition processes, creating uniform crystal structures at the microscopic level that ensure linear response characteristics for pressure transmission. When fluids or gases apply pressure to the ceramic diaphragm, it produces minute deformations that are converted into measurable electrical signals through resistive MEMS technology, achieving precise pressure value output.

SMD Board-Mount Design

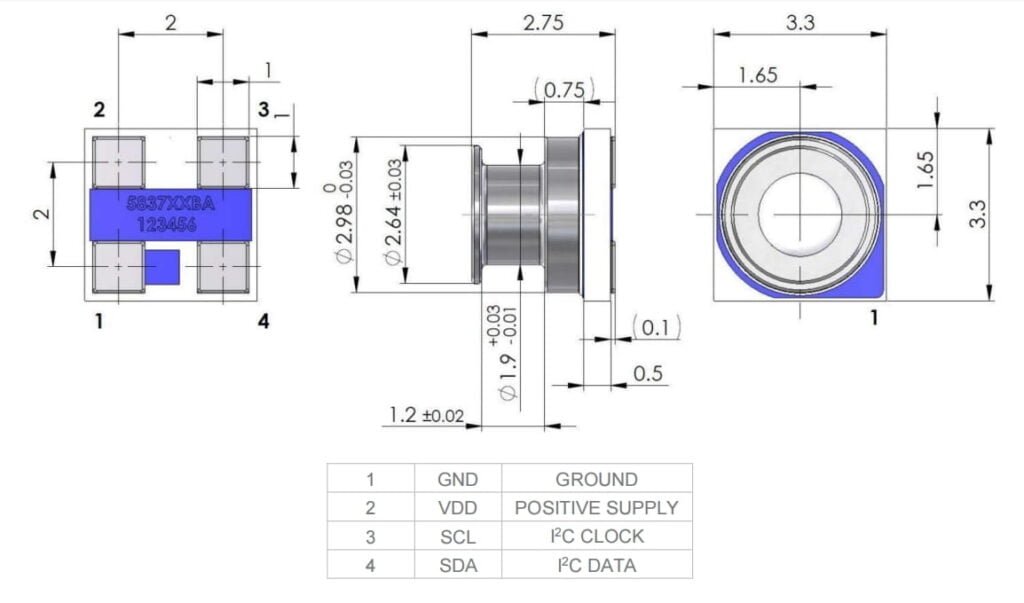

Modern ceramic pressure sensors utilize SMD surface-mount technology, allowing direct soldering to circuit boards and significantly reducing installation space requirements. This miniaturized design not only decreases overall system dimensions but also enhances signal transmission reliability. SMD packaging technology ensures stable connections under vibration and shock conditions while simplifying production assembly processes and reducing manufacturing costs.

Built-in Temperature Compensation Mechanism

Ceramic pressure sensors integrate built-in temperature sensors to achieve temperature-compensated measurement functionality. Temperature changes affect the resistive characteristics of ceramic materials, and built-in temperature compensation algorithms can real-time correct these influences, ensuring measurement accuracy across wide temperature ranges. This design is particularly suitable for outdoor environments and industrial applications with significant temperature fluctuations.

2. Fluid Pressure Monitoring Performance Specifications

High-Precision Measurement Capability

Ceramic pressure sensors deliver exceptional accuracy performance within a 7Bar measurement range, with resolution reaching 0.01% of full scale and response times typically within 1 millisecond. This high precision stems from ceramic material stability and advanced signal processing technology. Sensor nonlinearity error is controlled within 0.1%, ensuring consistent accuracy levels throughout the entire measurement range. Low noise design enables detection of minute pressure changes, meeting precision measurement application requirements.

Sampling Rate and Response Characteristics

Modern ceramic pressure sensors possess high sampling rate capabilities up to 1000Hz, capable of capturing rapidly changing pressure signals. Fast response rates make them suitable for dynamic pressure monitoring applications such as hydraulic systems, pneumatic control, and fluid pipeline monitoring. Sensor frequency response flatness maintains within ±1dB across the measurement bandwidth, ensuring signal authenticity and integrity.

Low Power Consumption Design

Ceramic pressure sensors employ low-power circuit design with operating currents typically ranging from 1-5mA and standby currents as low as tens of microamps. This low power consumption characteristic makes them particularly suitable for battery-powered portable devices and long-term monitoring applications. Sensors can operate normally under 3.3V or 5V power supplies, compatible with most microcontroller systems.

3. Reliability Standards and Certification Requirements

Durability Testing Standards

Ceramic pressure sensors must pass rigorous durability testing, including overload tests withstanding more than twice the maximum measurement pressure. This overload resistance ensures sensors won’t suffer permanent damage under unexpected pressure impacts. Mechanical shock testing requires sensors to withstand 1000g impact acceleration, while vibration testing covers 10-2000Hz frequency ranges, ensuring reliable operation in harsh environments.

Waterproof and Sealing Performance

Industrial-grade ceramic pressure sensors must meet IP67 or higher protection ratings, ensuring reliable operation in humid and dusty environments. Sealing design employs medical-grade compatible dielectric gel filling technology, providing excellent waterproof performance while ensuring chemical compatibility with measurement media. This design is particularly suitable for medical equipment and food industry applications.

Temperature Cycling and Thermal Shock Testing

The thermal shock resistance of ceramic materials enables sensors to operate stably within -40°C to +125°C temperature ranges. Temperature cycling tests require sensors to undergo more than 1000 cycles under extreme temperature conditions with accuracy drift not exceeding 0.1% full scale. Thermal shock testing verifies sensor stability under rapid temperature changes, ensuring long-term reliability in practical applications.

4. Performance Advantages and Adaptability

Chemical Stability and Corrosion Resistance

Ceramic pressure sensors combine excellent chemical resistance and stability, capable of direct contact with various corrosive media without chemical reactions. Ceramic materials exhibit superior corrosion resistance to most acids, alkalis, and salt solutions, enabling them to meet harsh requirements in industrial applications. Compared to metallic materials, ceramics don’t suffer performance degradation due to electrochemical corrosion, ensuring long-term measurement accuracy stability. This characteristic makes ceramic pressure sensors the preferred choice for chemical, pharmaceutical, and marine engineering applications in harsh environments.

Multi-Media Compatibility

Ceramic pressure sensors can measure various media including fluids, gases, and liquids, demonstrating broad application adaptability. The ceramic diaphragm doesn’t react chemically with most industrial media, ensuring measurement result accuracy and sensor service life. Whether dealing with high-temperature steam, corrosive liquids, or inert gases, ceramic sensors provide reliable pressure monitoring.

Standardized and Customized Options

Modern ceramic pressure sensors offer both standard and custom types to meet different application requirements. Standard sensors can replace common models like MS5837-02BA, providing plug-and-play solutions. Custom sensors can be designed according to specific pressure ranges, interface types, and packaging requirements, meeting special application scenario needs. This flexibility enables engineers to select the most suitable sensor configuration for their applications.

5. Measurement Accuracy Verification and Calibration Methods

Precision Measurement Tools and Equipment

Verifying ceramic pressure sensor accuracy requires high-precision reference standard equipment such as digital pressure calibrators, piston-type pressure gauges, and precision pressure controllers. These devices typically have accuracy grades of 0.01% or higher, ensuring calibration process accuracy. Pressure controllers should possess stable pressure output capability, providing uniformly distributed calibration points throughout the measurement range. Data acquisition systems need sufficient resolution and sampling rates to accurately record sensor output characteristics.

Temperature Compensation Verification

Testing temperature performance requires tests at different temperatures. The sensor is placed in a thermal chamber to simulate typical operating temperatures (for example, -40°C to +125°C). At each temperature point, a fixed pressure is applied and the output is recorded, then temperature drift and errors are evaluated. Effective temperature compensation makes the output only minimally affected by temperature. The temperature compensation algorithm’s effectiveness should be verified to ensure the sensor maintains high accuracy even at extreme temperatures. The final product should keep temperature-induced errors within its specifications.

Long-term Stability Monitoring

Long-term stability of ceramic pressure sensors is verified through continuous monitoring and periodic calibration. Monitoring procedures include evaluating zero stability, full-scale stability, and linearity retention capability. Comprehensive calibration is recommended every 6 months with monthly zero-point checks. By establishing historical databases, long-term performance change trends can be tracked, potential issues identified early, and preventive measures implemented.

Conclusie

Ceramic pressure sensors provide reliable technical solutions for fluid pressure monitoring through their unique material advantages and advanced manufacturing processes. Their miniaturized design, high-precision measurement, excellent chemical stability, and durability make them ideal choices for modern industrial applications. From technical principles to performance verification, ceramic pressure sensors demonstrate exceptional reliability standards in all aspects. As MEMS technology continues to develop, ceramic pressure sensors will play increasingly important roles in more fields, providing engineers and technical decision-makers with more accurate and reliable pressure monitoring capabilities.

De bovenstaande introductie schetst slechts het oppervlak van de toepassingen van druksensortechnologie. We zullen doorgaan met het verkennen van de verschillende soorten sensorelementen die in verschillende producten worden gebruikt, hoe ze werken en hun voor- en nadelen. Als u meer informatie wilt over wat hier wordt besproken, kunt u de gerelateerde inhoud verderop in deze handleiding bekijken. Als u weinig tijd heeft, kunt u ook hier klikken om de details van deze handleidingen te downloaden Luchtdruksensorproduct PDF -gegevens.

Voor meer informatie over andere sensortechnologieën kunt u terecht Bezoek onze sensorenpagina.