Catalogus

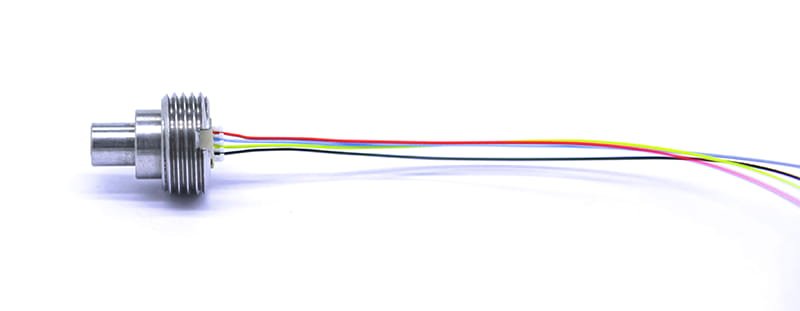

Water-meter hydraulics demand sensors that keep stable readings under liquid media, flow pulsation, and temperature shifts. A media-isolated design—metal diaphragm (stainless steel, titanium, or nickel alloy) + oil-filled cavity + silicon strain gauge—provides robust isolation. Choosing the right material, process connection, and output protocol, together with compensation and signal conditioning, improves reading consistency and eases system integration.

1. Key design decisions and material impact

Material choice sets long-term reliability in water meters. Stainless steel, titanium or nickel alloys give corrosion resistance and strength. Diaphragm size and connection control sensitivity and sealing.

2. Isolation and force transfer: principle and common distortion sources

Metal diaphragm transmits water pressure into an oil-filled cavity that passes force to the silicon strain gauge. Proper oil selection and vacuum de-bubbling prevent bubbles and reduce nonlinearity and measurement drift.

3. Amplification, ratiometric output and digital protocols’ role in stability

Stable output needs mechanical isolation and robust electronics. Amplification or ratiometric outputs raise bridge signals; digital I2C/SPI reduces noise and keeps calibration for linearization and traceability.

4. Temperature effects, compensation methods and validation steps

Temperature causes zero drift and sensitivity change. Match materials, use internal temperature sensing, and store multi-point compensation curves. Validate with temperature cycling, thermal shock and humidity tests.

5. Installation practice, mechanical isolation and lifetime verification points

Installation must avoid torque and radial stress. Use torque limiters, flush or welded mounts, and flexible adapters to protect the sensor. Verify with pressure cycling, vibration, shock and long-term zero-drift tests.

Samenvattingspunten

Material and diaphragm design determine long-term stability and corrosion resistance.

Vacuum de-bubbling and proper oil filling are essential to prevent drift.

Internal amplification, ratiometric outputs or digital I2C/SPI reduce system noise and improve integration.

Multi-point temperature calibration with onboard compensation maintains consistent readings.

Correct installation and full reliability testing prevent field-induced reading errors.

Conclusie

For water-meter hydraulics, media-isolated pressure sensors deliver stable, repeatable outputs when engineered with the right materials, robust isolation and filling methods, careful signal conditioning, and strict temperature and installation controls. Integrating these practices with factory calibration and traceable tests improves metering accuracy and lowers maintenance needs.

De bovenstaande introductie schetst slechts het oppervlak van de toepassingen van druksensortechnologie. We zullen doorgaan met het verkennen van de verschillende soorten sensorelementen die in verschillende producten worden gebruikt, hoe ze werken en hun voor- en nadelen. Als u meer informatie wilt over wat hier wordt besproken, kunt u de gerelateerde inhoud verderop in deze handleiding bekijken. Als u weinig tijd heeft, kunt u ook hier klikken om de details van deze handleidingen te downloaden Luchtdruksensorproduct PDF -gegevens.

Voor meer informatie over andere sensortechnologieën kunt u terecht Bezoek onze sensorenpagina.