Pressure sensors are used in a wide variety of applications such as industrial internet, consumer electronics, automotive, biomedical, aerospace, natural gas, chemical, mining, power, building automation, HVAC, food processing, pharmaceuticals, healthcare, environmental monitoring and more.

WF MEMS Pressure Sensor Applications

Inhoudsopgave

In the face of a wide range of types and models of pressure sensors, how do we choose a suitable sensor? WF will bring you a comprehensive answer to this question. In the selection process, we should focus on the use, pressure range, accuracy requirements, temperature range, electrical requirements, mode of operation, pressure sealing requirements and other indicators.

1. Confirm Measured Pressure Type

Pressure sensors can be classified into three main categories: absolute druk, relative pressure to the atmosphere and differential pressure. In the determination of absolute pressure, the sensor itself carries a vacuum reference pressure, and the pressure measured is not indicative of atmospheric pressure, but rather is relative to the vacuum pressure. The relative pressure of the atmosphere serves as the reference pressure for the atmosphere, thus ensuring that the elastic film side of the sensor is consistently linked to the atmosphere. Furthermore, it is feasible to introduce fluid pressure from both sides of the sensor’s elastic membrane, enabling the measurement of differential pressure at varying locations within the fluid or between fluids. The utilisation of diverse structural configurations for druksensoren is essential for optimising their performance in diverse applications.

2.Confirm Pressure Sensor Range

In general, it is necessary to select a sensor/transmitter with a pressure range approximately 1.5 times greater than the maximum value. In a multitude of test systems, particularly those utilising hydraulic measurement and processing, fluctuations are often observed, both in a discontinuous and irregular manner, as well as in a continuous and irregular manner. Such transient peaks have the potential to damage the pressure sensor, while continuously high pressure values or values slightly exceeding the calibrated maximum value of the sensor/transmitter will inevitably result in a reduction in the sensor’s operational lifespan.

In the event that the impact force exerted by the loader during the lifting moment is more severe on the sensor, a safe overload of more than three times is often required in such cases. However, this will affect the overall accuracy of the sensor. Damping devices can also be used to reduce the pressure impact, but this in turn reduces the response speed of the sensor. Therefore, when selecting a sensor/transmitter, it is important to take into account the pressure range, accuracy and stability in order to choose the most suitable solution.

3. Determine The Measurement Medium Of Pressure Sensor

In general, viscous liquids (e.g. crude oil), slurry, mud and other sediments have the effect of obstructing the pressure interface, which in turn affects the normal operation of the sensor. In order to ensure the correct functioning of the sensor, it is necessary to use isolation diaphragms (i.e. flat membrane structures) in sensors that are in direct contact with the medium for pressure measurement. In the event that the solvent contains corrosive substances, it is imperative to select a material that is compatible with these media as the isolation diaphragm. Otherwise, the product’s service life will be adversely affected.

4. Determine the accuracy of pressure sensors

In this context, accuracy is understood to encompass a range of characteristics, including non-linearity, hysteresis, repeatability, zero and full scale deviation, temperature and other environmental effects. It is important to note that the pursuit of higher precision in production inevitably entails the incorporation of additional processing techniques, calibration processes and compensation technology, which in turn lead to increased costs and a higher sales price. Consequently, when selecting products, it is essential to consider not only precision but also the specific measurement needs of the intended application.

5.Confirm the temperature range of pressure sensor

A transmitter is usually marked with two temperature ranges, the normal operating temperature range and the temperature compensable range.

Normal operating temperature range: The temperature range in which the product will operate without damage and in which the product may fail to meet its specified performance if the temperature compensation range is exceeded.

Temperature Compensation Range: The range within which the product will reliably meet its performance targets.

Temperature variations affect the zero drift and full scale output, thus affecting the accuracy of the pressure sensor. Various temperature compensation techniques are used to eliminate the effects of temperature. The wider the temperature range, the more difficult the compensation technique, the greater the calibration effort and the lower the guaranteed accuracy over the full temperature range. Reasonable requirements should be made based on the actual temperature range and accuracy requirements of the pressure sensor application.

6. Electrical Requirement

The output of normal pressure sensors is an analogue signal and the voltage of the output signal degrades with distance, so a current signal output should be used. A current signal of 20mA or less can be output by amplifying the current through a pressure transmitter. This will multiply the price.

The type of output you choose will therefore depend on the distance between your sensors and the system control or display components, noise and other electrical interference, the need for amplification, the best location for the amplifier, etc.

In addition, digital and frequency signals can only be obtained after A/D and V/F conversion.

Constant current sources and constant voltage sources are the two types of excitation sources commonly used in sensors. The two excitation methods are different and serve different purposes. Constant current excitation is advantageous in compensating for thermal sensitivity drift. The type of output can determine the excitation voltage required. Many amplified sensors have built-in voltage regulators and can operate over a wide range of unregulated voltage sources.

Some sensors are proportional and require a regulated excitation source. The power supply used will determine whether you use a regulated or unregulated source. This requires a compromise between system cost and all sources of excitation.

Pressure sensors can be powered by batteries, but more commonly DC regulated power technology is used.

7. Operation mode

The operating environment is also an important consideration. When pressure sensors are used in harsh environments, such as high levels of vibration, shock and electromagnetic interference, more stringent requirements are placed on the sensors. Not only is the overpressure capacity high, but reliable mechanical sealing, loosening protection and correct sensor installation are also required. The sensor’s own leads, pins and external wires should be electromagnetically shielded and the shielding should be well grounded.

8. Requirements for pressure seals

The pressure seals normally used are rubber gaskets (or O-rings), epoxy, PTFE , taper hole fits, pipe thread fits and welding. The sealing material used determines the operating temperature range of the pressure sensor.

9.END

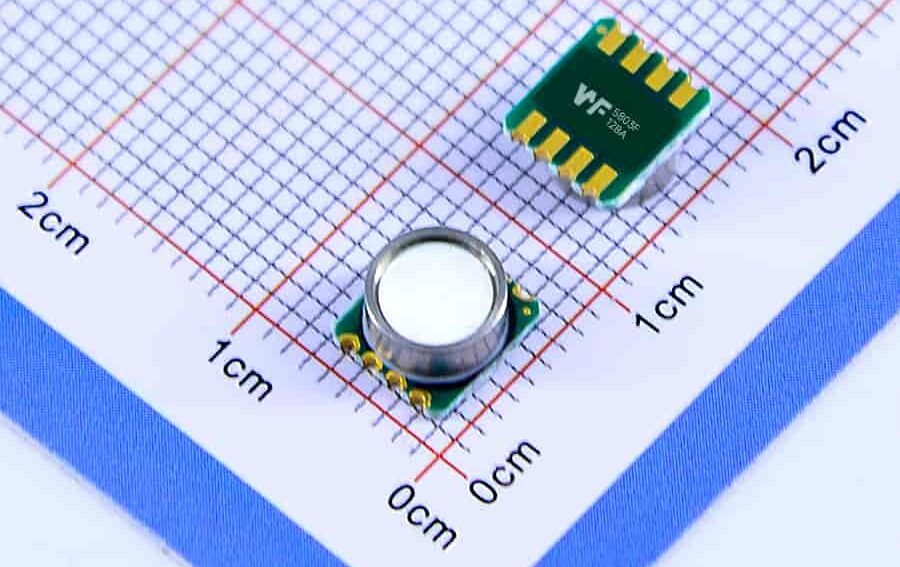

Through this WF editorial, I believe you have a comprehensive understanding of how to select the druksensor, in short, to choose the right pressure sensor, you need to consider a number of factors. WFsensor has been increasing R & D, optimisation of chip size, sensitive film thickness uniformity, temperature drift self-compensating structure, and make full use of the innovative technology of the independent packaging and testing workshop, so that its performance and quality of imported and exported products up to the level of the product, the product has a high degree of accuracy, anti-interference, anti-shock, anti-corrosion, and low power consumption, strong reliability and so on, are widely used in the field of consumer electronics, automotive electronics, industrial, medical and other fields. The products are widely used in consumer electronics, automotive electronics, industrial electronics and medical fields.