With the continuous advancement of science and technology, MEMS technology is increasingly used in various fields, especially in the field of sensors. Pressure sensor is one of the best application fields of MEMS technology. It has the advantages of high precision, high sensitivity, small size, low power consumption, etc., and is widely used in industry, medical, automobile, aviation and other fields.

Then let’s take a look at the design and manufacturing of pressure sensors based on MEMS technology.

1. Structure and principle of pressure sensor

Pressure sensors generally consist of sensing elements, signal processing circuits, output circuits and casings. Among them, the sensing element is the core component of the pressure sensor, which can convert the received physical quantity into an electrical signal. According to different working principles, sensing elements can be divided into resistive strain pressure sensors, capacitive pressure sensors and micro-mechanical pressure sensors.

The micromechanical pressure sensor is manufactured using MEMS technology. Its main structure includes a diaphragm, a cavity, a conductive layer, a fixed layer, etc. When pressure acts on the diaphragm of the sensor, a slight flexural deformation will occur. This deformation will cause a slight change in the distance between the conductive layer and the fixed layer on the diaphragm, thus changing the capacitance value, and then calculating the result. The amount of pressure received.

2. Characteristics of MEMS pressure sensors

Due to the use of MEMS technology, MEMS druksensoren have various characteristics, such as small size, light weight, high accuracy, fast response, high reliability, and low energy consumption. Its sensitivity can reach 1pa, and the error is less than 0.2%. At the same time, MEMS pressure sensors also have characteristics such as earthquake resistance and anti-interference, and are suitable for applications in complex environments.

3. Manufacturing process of MEMS pressure sensors

The manufacturing process of MEMS pressure sensors mainly includes wafer processing, cavity processing, conductive layer processing, packaging and other links.

Wafer processing is the first step in manufacturing MEMS sensors, and its operation needs to be carried out in a purified, dust-free environment. MEMS wafer manufacturing technology draws on the manufacturing process of integrated circuit substrates, using photoresist processes, mask processes, evaporation processes and other methods to integrate sensing elements, control circuits and connection pins on the same wafer.

Cavity processing is the process of cutting, etching, and bonding wafers to form the cavity structure of the sensor. This process requires mastering technologies such as blade cutting, laser etching, and ion beam etching.

Conductive layer processing is one of the common processes in which metals such as copper and aluminum are made into thin films and processed using photolithography technology to form components such as varistors or capacitors. At the same time, electron beam or micro-ray methods are also used to manufacture micro conductor structures.

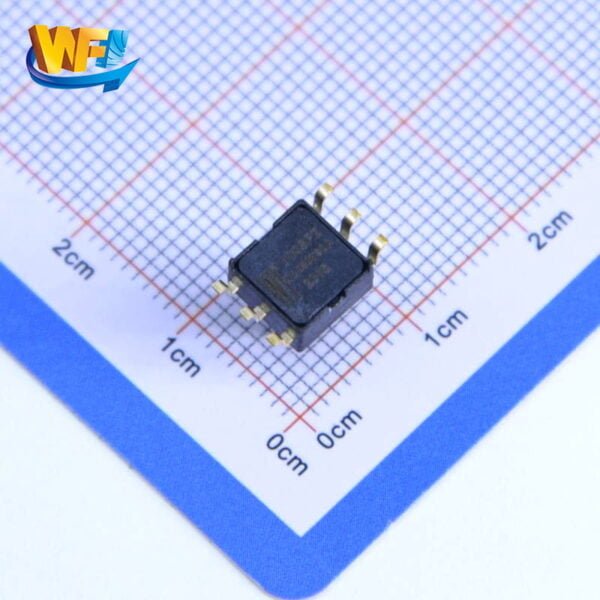

Packaging is to ensure the sealing of MEMS components under usage conditions, and it is also one of the most difficult aspects. MEMS -sensoren are generally packaged using wafer level packaging (CSP), plastic packaging and other processes.

4. Future development of MEMS pressure sensors

With the continuous advancement of technology and the wide application of MEMS sensors in various fields, it is predicted that future MEMS pressure sensors will have the following characteristics:

1. Diversified structure. At present, most MEMS pressure sensors are based on pressure-sensitive components with a single structure. Future pressure sensors require more flexible multi-stage and multi-structure designs.

2. Improved accuracy. MEMS pressure sensors have excellent accuracy, but in future development, their accuracy and signal-to-noise ratio will continue to be improved to provide more accurate measurement capabilities for various applications.

3. Reduced power consumption. MEMS druksensoren consume electricity, and future development requires better reduction of their power consumption to achieve lower energy consumption.

Summarize:

In short, pressure sensors based on MEMS technology have broad application prospects, high technical content and good market prospects. With the continuous improvement of manufacturing technology and the expansion of application scope, it is believed that MEMS pressure sensors will provide more complete and Betrouwbare meetoplossingen in various fields.