Fietscomputer met luchtdruksensor voor realtime windsnelheid

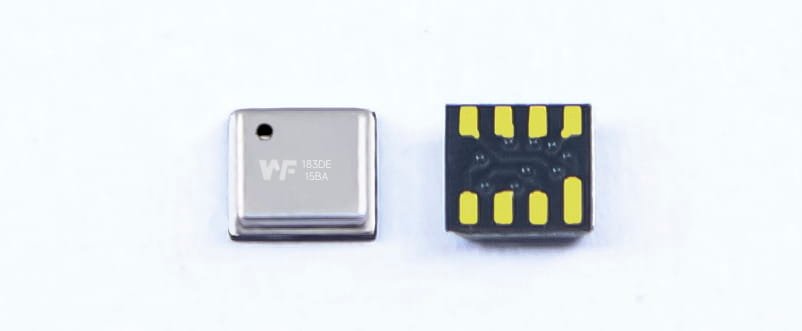

MEMS air pressure sensor enables precise wind speed measurement in bicycle computers using resistive technology, featuring low power consumption, waterproof design, and temperature compensation for reliable real-time environmental data.

-e1747998312687.jpg)