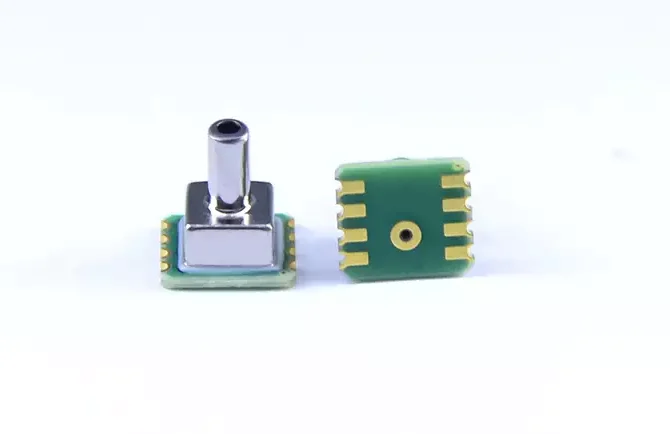

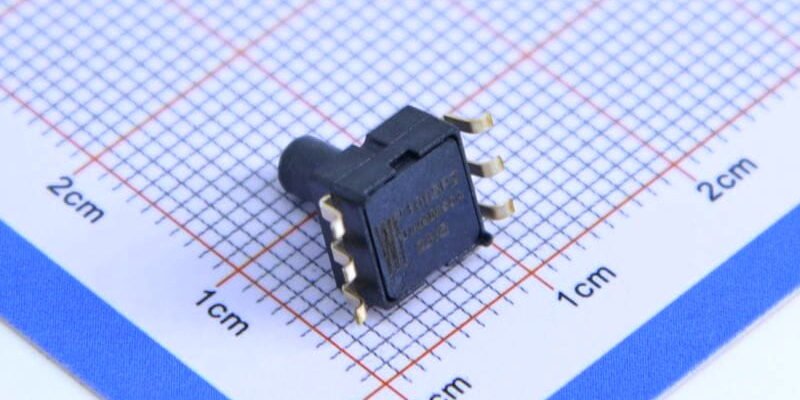

WF druksensor in bloeddrukhorloge van Applicatie

Pressure sensors are the most important technical component of blood pressure watches. Their application not only realizes convenient blood pressure measurement, but also provides intelligent solutions for health management. With high precision sensors and advanced algorithms, blood pressure watches can provide accurate real-time data and health trend analysis to help users better manage their personal health.