I sensori di vuoto a pressione assoluta sono componenti critici nelle moderne macchine per la pulizia dei vetri, poiché garantiscono un controllo ottimale dell'aspirazione, efficienza energetica e sicurezza. Questi sensori misurano la pressione relativa a un vuoto perfetto, consentendo un monitoraggio preciso delle forze di aspirazione anche in condizioni atmosferiche variabili. Questo articolo ne esplora i principi di funzionamento, i vantaggi rispetto ai sistemi tradizionali, i criteri di selezione, le migliori pratiche di installazione e le applicazioni del mondo reale. I dati del settore mostrano che l’integrazione di questi sensori può ridurre il consumo di acqua fino al 30% e migliorare l’efficienza della pulizia del 25% nei sistemi di pulizia delle finestre dei grattacieli.

Catalogare

1. Introduzione ai sensori di vuoto e pressione assoluta

I sensori di vuoto a pressione assoluta hanno rivoluzionato la pulizia automatizzata delle finestre fornendo il monitoraggio della forza di aspirazione in tempo reale. A differenza dei sensori di pressione relativa, che misurano rispetto alla pressione atmosferica, i sensori assoluti fanno riferimento a una camera a vuoto sigillata, eliminando gli errori causati dall'altitudine o dai cambiamenti meteorologici. Questa stabilità è fondamentale per i sistemi di pulizia dei grattacieli, dove un'aspirazione costante previene i rischi di distacco.

Si prevede che il mercato globale di questi sensori crescerà a un CAGR del 7,2% fino al 2030, spinto dalla domanda di soluzioni di pulizia ecocompatibili

2. Come funzionano i sensori di pressione assoluta nei sistemi di pulizia delle finestre

2.1 Componenti principali e principi di misurazione

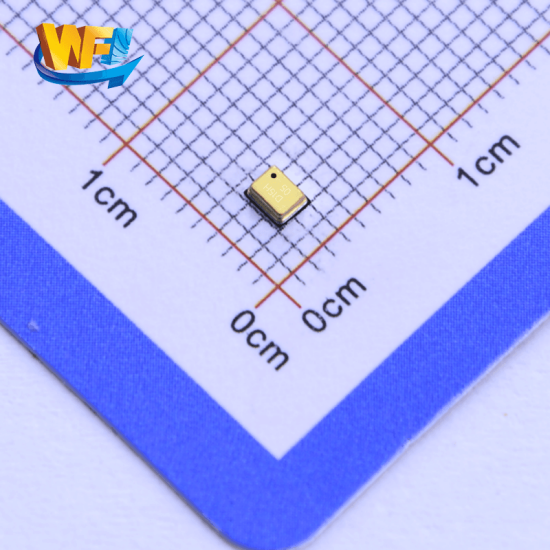

Questi sensori contengono un diaframma piezoresistivo MEMS che si flette in caso di variazioni di pressione. La resistenza del diaframma varia proporzionalmente al vuoto applicato, convertito in segnali elettrici (ad esempio, 5,4 uA o 1,7–3,6 V) per il controllo del sistema. Ad esempio, la serie WF282A di WFsensors raggiunge una precisione di ±0,1% su intervalli di 0-1 bar, garantendo prestazioni affidabili nei lavavetri idraulici

2.2 Calibrazione per la stabilità ambientale

Per mantenere la precisione, i sensori sono sottoposti a compensazione della temperatura da 0°C a +80°C. Il modello WF282A mantiene una precisione a fondo scala dello 0,05% anche dopo 100.000 cicli di pressione, fondamentale per l'uso commerciale quotidiano. Si consiglia la calibrazione rispetto agli standard tracciabili NIST ogni due anni.

3. Vantaggi dei sensori di vuoto nelle macchine per la pulizia dei vetri

3.1 Efficienza energetica e risparmio idrico

Regolando dinamicamente la velocità della pompa in base ai dati del vuoto in tempo reale, i sensori riducono il consumo energetico del 15–20%. IL Robot per la pulizia delle finestre Il sistema dimostra come il sensore digitale abbinato ai controller intelligenti riduca al minimo lo spreco d'acqua durante il risciacquo dei grattacieli

3.2 Miglioramenti della sicurezza per le operazioni nei grattacieli

Un'improvvisa perdita di aspirazione può causare il distacco dell'apparecchiatura. I sensori assoluti attivano allarmi istantanei se la pressione scende al di sotto dell'80% del valore target, offrendo agli operatori una finestra di risposta di 3-5 secondi. I protocolli di test MEMS di WF garantiscono l'affidabilità del sensore del 99,99% con carichi di vibrazione fino a 10 g

4. Selezione del sensore giusto per la tua macchina

4.1 Intervallo di pressione e considerazioni sulla compatibilità

Abbina la portata massima del sensore alla capacità della tua pompa. Per le unità residenziali sono sufficienti sensori da 0–1 bar (ad esempio WF280A), mentre i sistemi industriali richiedono modelli da 0–10 bar come WF183DE. Conferma la compatibilità elettrica: 5,5 V CC è lo standard per i dispositivi abilitati per IoT.

4.2 Durabilità in ambienti difficili

Optare per custodie con grado di protezione IP65 se esposti all'umidità. I sensori WF resistono all'esposizione chimica a pH 1–14, ideali per applicazioni con uso intensivo di detergenti

5. Migliori pratiche di installazione e manutenzione

5.1 Guida passo passo all'integrazione del sensore

- Montare il sensore entro 1 m dalla porta del vuoto per ridurre al minimo il ritardo.

- Utilizzare nastro in PTFE sulle connessioni filettate per evitare perdite.

- Connettiti a <colore carattere=”rosso”>Sensori WF282A</font> per la conversione da analogico a digitale.

- Eseguire il test utilizzando un vacuometro portatile (precisione consigliata ±2%).

5.2 Risoluzione dei problemi comuni

Letture alla deriva: Ricalibrare o sostituire i diaframmi ogni 2 anni.

Rumore del segnale: Installare i nuclei di ferrite sui cavi di alimentazione.

6. Caso di studio: storia di successo dell'attaccamento Vak-Head

Secondo il feedback degli utenti dell'hotel, la produttività è aumentata del 55% dopo aver integrato i sensori assoluti nella loro macchina lavavetri. L'intervallo 0-1.000 mbar del sensore ha consentito un controllo preciso durante le pulizie di hotel di 30 piani, riducendo il consumo di acqua per finestra a 50 ml

7. Tendenze future nella tecnologia dei sensori

I sensori basati su MEMS con uscite I²C (ad esempio, la serie WF100DP) domineranno a causa della compatibilità IoT. I ricercatori stanno sviluppando diaframmi in grafene per intervalli da 0 a 15 bar con una precisione dello 0,01%, il cui lancio commerciale è previsto entro il 2027

Conclusione

I sensori di vuoto a pressione assoluta sono indispensabili per una pulizia efficiente e sicura delle finestre. Selezionando sensori con gamme adeguate, garantendo un'installazione corretta e sfruttando progressi come la tecnologia MEMS, gli operatori possono ottenere notevoli risparmi sui costi e vantaggi ambientali. Per consigli personalizzati consultare La guida dei sensori WF oppure contatta il team tecnico di WF

L'introduzione di cui sopra scalfisce solo la superficie delle applicazioni della tecnologia dei sensori di pressione. Continueremo a esplorare i diversi tipi di elementi sensore utilizzati nei vari prodotti, come funzionano e i loro vantaggi e svantaggi. Se desideri maggiori dettagli su ciò che viene discusso qui, puoi consultare il contenuto correlato più avanti in questa guida. Se hai poco tempo, puoi anche fare clic qui per scaricare i dettagli di queste guide Dati PDF del sensore del sensore di pressione dell'aria.

Per ulteriori informazioni su altre tecnologie di sensori, per favore Visita la nostra pagina dei sensori.

Penso che l'amministratore di questo sito web stia davvero lavorando duro a favore

della sua pagina web, poiché qui ogni informazione è basata sulla qualità.