What should we pay attention to when using pressure sensors?

Selection Tips

1. When selecting a model, please note that the measured medium must be compatible with the part of the product that contacts the medium.

2. Many piezoresistive sensor elements can only support dry, non-corrosive gases.

Precautions for use

1. Soldering Since this product has a small structure with low heat capacity, please minimize the influence of heat from the outside. Otherwise, it may be damaged due to thermal deformation and cause changes in characteristics. Please use non-corrosive rosin-type flux. In addition, since the product is exposed to the outside, be careful not to allow flux to penetrate into the inside.

1) Hand soldering – Use a soldering iron with a tip temperature of 260°C (30 W) and perform the work within 5 seconds. – When applying a load to the terminal for soldering, the output may change, so be careful. – Please clean the tip of the soldering iron thoroughly.

2) DIP soldering (DIP terminal type) – Perform the work within 5 seconds in a DIP solder bath at a temperature of 260°C or less. – When mounted on a substrate with a small heat capacity, thermal deformation may occur, so pay attention to temperature control.

3) After mounting the sensor, be careful not to generate stress on the soldered part when cutting and bending the substrate.

4) Since the sensor terminals are exposed, abnormal output may occur if metal pieces touch the terminals. Be careful not to touch them with metal pieces or hands. Prevent electrostatic breakdown.

5) After soldering, when coating to prevent insulation deterioration of the substrate, be careful not to allow chemicals to adhere to the sensor.

Cleaning requirements

1) Since the product is open, be careful not to allow the cleaning fluid to enter the inside.

2) When using ultrasonic cleaning, it may cause product failure, so please avoid using ultrasonic cleaning.

Storage and Transportation

1) This product is not drip-proof, so do not use it in places where it may be splashed with water.

2) Do not use it in an environment where condensation occurs. In addition, if the moisture attached to the sensor chip freezes, it may cause changes in sensor output or damage.

3) The pressure sensor chip is structurally exposed to light, and the output will change. Especially when applying pressure through a transparent cover, please avoid light from contacting the sensor chip.

4) Normally packaged pressure sensors can be transported by ordinary transportation tools. Please note: The product should be protected from moisture, impact, sunburn and pressure during transportation.

Other precautions for use

Other precautions for use

1) If the installation method is incorrect, it may cause an accident, so be careful.

2) Please avoid using methods that apply high-frequency vibrations such as ultrasonic waves.

3) The only pressure medium that can be used directly is air. Other media, especially when used in corrosive gases (organic solvent gas, sulfurous acid gas, hydrogen sulfide gas, etc.), foreign matter media, will cause malfunctions and damage, so

Please avoid using it in the above environment.

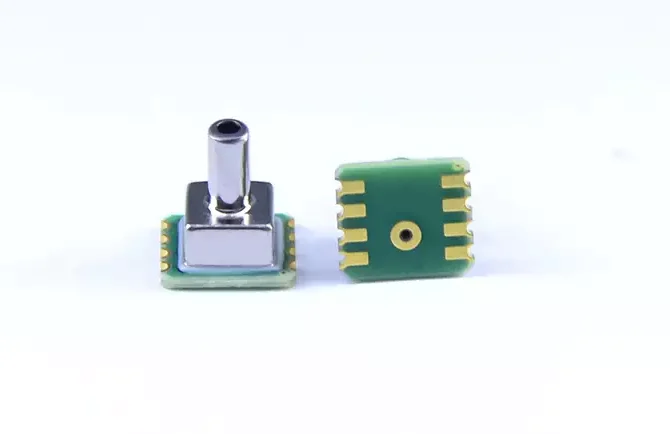

4) The pressure inlet is equipped with a pressure sensor chip. If a foreign object such as a needle is inserted from the pressure inlet, the chip will be damaged and the inlet will be blocked, so please absolutely avoid the above operations. In addition, please avoid blocking the atmospheric inlet when using it.

5) Regarding the operating pressure, please use it within the rated pressure range. If used outside the range, it will cause damage.

6) Since it may be damaged by static electricity, please be careful when using it: please ground the charged objects on the table and the operator to discharge the surrounding static electricity safely.

7) Depending on the pressure used, please pay full attention to the fixing and selection of the product and the sleeve and inlet tube.

8) This product is made using semiconductor components for general electronic equipment (communication equipment, measuring equipment, machine tools, etc.). Products using these semiconductor components may malfunction and fail due to external interference and surges, so please confirm the performance and quality under actual use. To be on the safe side, please perform safety design on the device (installation of protection circuits such as fuses and circuit breakers, multiple devices, etc.) so that even if a malfunction occurs, it will not harm life, body, property, etc.

Safety Precautions

To prevent injuries and accidents, please be sure to follow the following:

· The drive current and voltage should be used below the rated value.

· Please wire according to the electrical definition. In particular, reverse connection of the power supply may cause accidents due to circuit damage such as heating, smoke, and fire, so please be careful.

· Please be careful when fixing the product and connecting the pressure inlet.