Catalogare

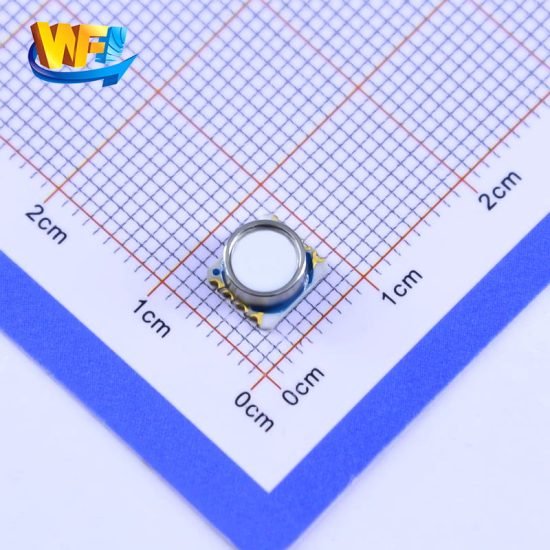

MEMS pressure sensors are redefining intelligent standards in instrumentation through microelectromechanical systems technology, achieving unprecedented measurement accuracy and response speed.

1. Intelligent Breakthrough in Pressure Range and Accuracy

Tecnologia di adattamento dinamico a gamma completa

MEMS pressure sensors demonstrate intelligence through wide pressure range coverage from 0.1kPa to 10MPa. Dynamic adaptation enables instruments to automatically adjust measurement ranges without manual intervention, significantly improving monitoring continuity and reliability.

Precisione relativa e ottimizzazione della risoluzione

Intelligent processing of relative accuracy represents the core advantage of MEMS sensors. Built-in temperature compensation algorithms and nonlinear correction ensure stable relative accuracy under different environmental conditions.

2. Temperature Compensation and Working Environment Adaptability

Meccanismo intelligente di compensazione della temperatura

Temperature compensation functionality is key technology for intelligent monitoring. Built-in temperature sensing elements monitor environmental temperature changes in real-time, automatically adjusting pressure measurements through digital signal processing chips.

Gestione intelligente della tensione di lavoro

Intelligent voltage management allows MEMS sensors to adapt to different power supply environments. Wide voltage operation from 3.3V to 5V, combined with low power design, enables instruments to work normally under battery power or unstable power conditions.

3. Response Speed and Noise Control Technology

Risposta ad alta velocità ed elaborazione in tempo reale

Fast response characteristics of MEMS pressure sensors provide important foundation for intelligent monitoring. Millisecond-level response time enables instruments to track pressure changes in real-time, crucial for dynamic process monitoring.

Soppressione del rumore e ottimizzazione del segnale

Low noise characteristics represent important manifestation of MEMS sensor intelligence. Advanced signal processing technology controls noise levels within extremely low ranges, ensuring measurement data reliability.

4. Wide Pressure and Bidirectional Pressure Monitoring

Riconoscimento intelligente ad ampio intervallo di pressione

Wide pressure monitoring capability allows MEMS sensors to handle full-range pressure measurement from vacuum to high pressure. Intelligent recognition algorithms automatically judge current pressure states and adjust measurement parameters.

Monitoraggio bidirezionale della pressione positiva e negativa

Bidirectional monitoring of positive and negative pressure is an important feature of MEMS sensor intelligence. Sensors accurately distinguish pressure directions and provide corresponding measurement data.

5. Digital Integration and Intelligent Decision Making

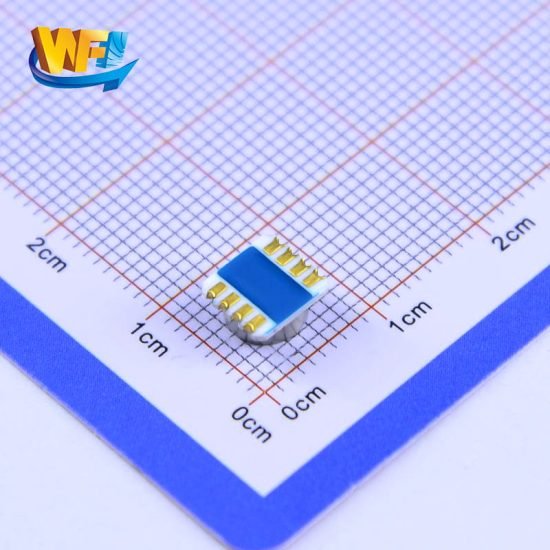

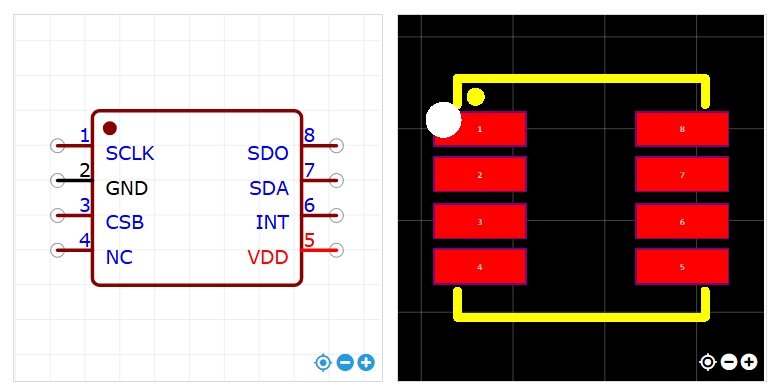

Interfaccia digitale e integrazione di sistema

Digital interface design of MEMS pressure sensors enables easy integration into modern intelligent instrument systems. Through I2C, SPI standard communication protocols, sensors connect directly with microcontrollers.

Algoritmi intelligenti e analisi predittiva

Integrated intelligent algorithms enable MEMS sensors to provide real-time pressure data and perform trend analysis and anomaly detection. Machine learning algorithms learn normal working mode pressure characteristics.

Conclusione

MEMS pressure sensors are driving instrumentation monitoring technology to higher levels through excellent technical characteristics and intelligent functions. These technological advances not only improve measurement accuracy and reliability but provide solid technical foundation for intelligent manufacturing in Industry 4.0 era.

L'introduzione di cui sopra scalfisce solo la superficie delle applicazioni della tecnologia dei sensori di pressione. Continueremo a esplorare i diversi tipi di elementi sensore utilizzati nei vari prodotti, come funzionano e i loro vantaggi e svantaggi. Se desideri maggiori dettagli su ciò che viene discusso qui, puoi consultare il contenuto correlato più avanti in questa guida. Se hai poco tempo, puoi anche fare clic qui per scaricare i dettagli di queste guide Dati PDF del sensore del sensore di pressione dell'aria.

Per ulteriori informazioni su altre tecnologie di sensori, per favore Visita la nostra pagina dei sensori.