Catalogare

Depth detection sensors work on the basis of hydrostatic pressure. With compact MEMS devices like the WF5805-05BA, plus sealing and signal electronics, pressure is quickly converted into reliable depth readings. For underwater robots, diving systems and control platforms, these sensors are critical to achieving precise positioning and stable control.

1. Sensor and hardware traits

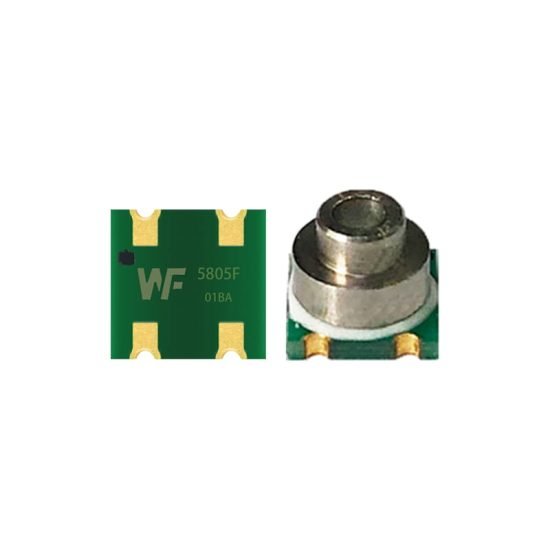

WF5805-05BA and similar MEMS sensors

The WF5805-05BA is part of a family of high-precision MEMS absolute/relative pressure sensors, usually in small SMD packages with a metal port on top. The silicon element inside is micro-machined for high sensitivity and low temperature drift, while the pins and sealing materials make it reliable in long-term use. These features suit ROVs, AUVs and diving gear where repeatability and linearity are vital.

2. Operating principle and depth conversion

From water pressure to depth

What the sensor measures is static water pressure. The physics is simple: pressure rises with depth, ΔP = ρ·g·Δh. The sensor’s voltage or digital signal is corrected using calibration factors, local density and gravity, then converted into depth. For accuracy, systems also allow for temperature and salinity changes that affect water density, adding those as compensation terms.

3. Packaging, sealing and interface design

Packaging for deployment in the field

A depth sensor for underwater work has to balance pressure tolerance, corrosion resistance and electrical isolation. WF5805-05BA types often use a metal port or isolation diaphragm, sealed with epoxy, in a solder-mount package. Design considerations include avoiding blockage, preventing electrochemical corrosion, and controlling drift over long immersion periods.

4. Data handling, sampling and accuracy assurance

From raw sensor output to usable depth

Accurate depth control depends on sampling stability, clean signal amplification and precise ADC conversion. Key points are choosing a sampling rate that balances bandwidth with filter delay, adding compensation for temperature and salinity, and building error budgets and drift monitoring into firmware. Calibration of zero, span and curve makes sure depth readings stay within engineering tolerance.

5. Precision control in underwater engineering

How sensors improve control and execution

Integrating accurate depth feedback into a control loop boosts the fine-tuning of thrusters and rudders, cutting overshoot and oscillation. For operations like pipeline laying, survey marker positioning or close-to-seabed work, stable sensor readings reduce convergence time and steady-state error. In short, better sensor stability allows tighter gain settings and more robust fault tolerance in controllers.

Conclusione

Depth detection sensors built on MEMS pressure elements, combined with robust packaging and solid data handling, turn water pressure into reliable depth data. For underwater projects, selecting the right device (such as the WF5805-05BA), optimising sealing and interfaces, and enforcing calibration are the foundation of accurate and stable control.

L'introduzione di cui sopra scalfisce solo la superficie delle applicazioni della tecnologia dei sensori di pressione. Continueremo a esplorare i diversi tipi di elementi sensore utilizzati nei vari prodotti, come funzionano e i loro vantaggi e svantaggi. Se desideri maggiori dettagli su ciò che viene discusso qui, puoi consultare il contenuto correlato più avanti in questa guida. Se hai poco tempo, puoi anche fare clic qui per scaricare i dettagli di queste guide Dati PDF del sensore del sensore di pressione dell'aria.

Per ulteriori informazioni su altre tecnologie di sensori, per favore Visita la nostra pagina dei sensori.