Integrated pneumatic valves demand fast, reliable pressure feedback. Gauge sensors strike a balance between range and resolution, and digital outputs that speak directly to an MCU simplify hardware and boost noise immunity. This write-up focuses on using small, easy-to-install, and calibrated digital pressure sensors to achieve multi-point sampling, I²C bus sharing and closed-loop control based on pressure feedback, emphasising practical engineering steps and system stability.

Каталог

1. Design starting points and system requirements

Sampling needs centred on closed-loop stability

In an integrated pneumatic valve, the stability of the primary pilot chamber directly affects repeatability and response time. The design should first define the minimum pressure resolution and update rate the closed-loop controller needs — in other words, the smallest change that must be detected within the control period. Gauge sensors measure pressure relative to atmosphere, so they’re well suited to multi-chamber, multi-point sampling and make it straightforward for a PID controller to decide on fine charge/discharge actions. That leads to smaller steady-state error and faster suppression of disturbances.

2. Sensor selection and key specifications

Balancing range, resolution and the digital interface

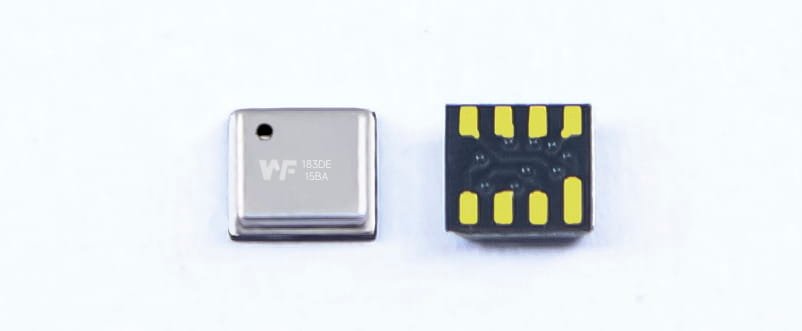

Pick sensors that meet range, accuracy and simplicity requirements. For this project, the −100 kPa to 1000 kPa span covers negative and mid-to-high pressures, while a 24-bit ADC delivers the resolution needed for the controller to notice subtle drifts. A digital I²C output reduces analogue front-end complexity and improves immunity to interference. From a packaging perspective, the WF100DPZ-style SOP form factor is compact and easy to mount on the board; it contains the sensing die and signal-processing IC inside the housing, supports temperature compensation and calibration, and suits volume production with consistent performance.

3. Hardware integration and peripheral circuitry

Multi-sensor I²C sharing and chip-select implementation

When I²C addresses are limited, use four sensors with a data selector (or an I²C multiplexer) and control chip-select with MCU GPIOs to manage multiple devices on a single bus. The MCU toggles the multiplexer’s A0/A1 pins (or sets GPIO levels) to pick the desired sensor, then uses I²C to send commands and read results. This reduces PCB footprint and wiring complexity and simplifies firmware. Still, power filtering, pull-ups and careful layout remain critical to maintain signal stability and noise immunity.

4. Closed-loop control and data handling essentials

PID loop using pressure feedback and disturbance handling

The closed-loop uses the pressure reading as feedback; PID gains must be tuned to cope with gas charge/discharge non-linearity and system delay. Apply filtering (simple low-pass or a Kalman filter) before using readings to strip high-frequency noise while keeping enough bandwidth for control. Put the sensor’s temperature compensation and calibration coefficients into firmware so readings remain consistent across temperatures. For sudden leaks or blocked fill lines, add threshold triggers that run safety logic and log diagnostics for maintenance and remote analysis.

5. Testing, calibration and performance acceptance

From single-point error to system-level stability checks

During debugging, use I²C to exchange commands between MCU and sensor module, then read and log the values for display. Test multiple pressure points to check linearity and accuracy. Example tests show at several points (e.g. 100, 200, 300, 400 kPa) errors remain within ±5%FS, meeting system design needs. Acceptance should include individual sensor calibration, temperature-cycle checks, and system-level tests for closed-loop response time and steady-state error to ensure the valve holds the set pressure within required bounds in target conditions.

Висновок

Using gauge-type digital pressure sensors (−100 kPa to 1000 kPa, 24-bit ADC, I²C output, WF100DPZ-style packaging) together with I²C multiplexing, MCU chip-select and appropriate filtering plus PID control enables compact, fast and stable closed-loop pressure control for integrated pneumatic valves. The solution simplifies hardware, improves noise immunity and speeds engineering implementation, easing production and maintenance.

Наведене вище введення лише дряпає поверхню застосування технології датчиків тиску. Ми продовжимо досліджувати різні типи сенсорних елементів, які використовуються в різних продуктах, як вони працюють, а також їхні переваги та недоліки. Якщо вам потрібна додаткова інформація про те, що тут обговорюється, ви можете переглянути відповідний вміст далі в цьому посібнику. Якщо у вас немає часу, ви також можете клацнути тут, щоб завантажити докладну інформацію про ці посібники Дані датчика тиску повітря PDF.

Для отримання додаткової інформації про інші сенсорні технології, будь ласка Відвідайте нашу сторінку датчиків.