With the popularity of smart homes and consumers increasing requirements for kitchen environment quality, range hoods have gradually transformed from traditional exhaust equipment to core kitchen equipment with intelligent control. The application of датчики тиску in range hoods not only effectively improves the performance of range hoods, but also provides accurate basic data for intelligent control.

Почнемо розбиратися!

Каталог

Pressure sensor work principle

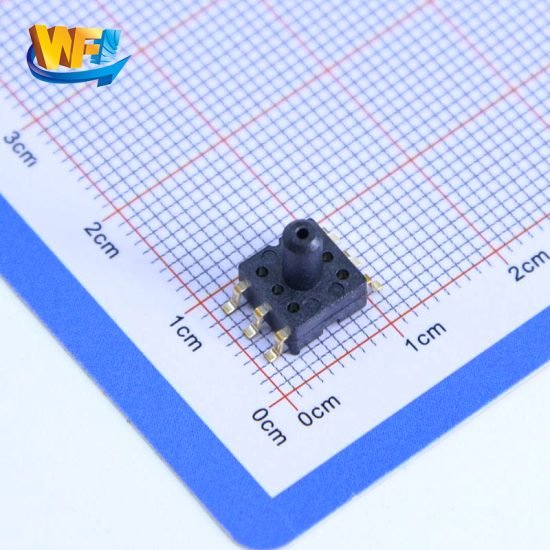

The pressure sensor senses the pressure change of the air flow inside the system and converts it into an electrical signal output. Commonly used sensor types include gauge pressure sensor and differential pressure sensor. Gauge pressure sensor measures the pressure relative to the atmosphere, while differential pressure sensor is suitable for monitoring the pressure difference between the inside and outside of the oil fume duct.

pressure sensors in range hoods Functions

Flue blockage detection

If a blockage occurs in the fume duct, the internal pressure will increase abnormally. The pressure sensor monitors the duct pressure in real time. When the pressure exceeds the set threshold, the range hood can automatically sound an alarm to remind the user to clean the duct.

Intelligent wind speed adjustment

The amount of fume generated is related to the cooking method. The pressure sensor can sense the changes in the airflow pressure in the flue and adjust the fan speed in real time to achieve efficient smoke exhaust and reduce energy consumption.

Filter cleaning reminder

When the filter of the range hood is blocked by oil, the airflow resistance increases, causing the pressure to rise. By monitoring this change with the pressure sensor, the system can determine whether the filter needs to be cleaned and remind the user.

Suction optimization

In different environments (such as high-rise buildings or different seasons), changes in external air pressure may affect the exhaust effect of the range hood. Through the feedback of the pressure sensor, the range hood can automatically adjust the fan working mode to ensure the best suction.

Technical selection suggestions

Sensor type selection

- Gauge pressure sensor: suitable for conventional kitchen environments, relatively inexpensive.

- Differential pressure sensor: suitable for range hood systems that require high-precision airflow monitoring.

Pressure range selection

- For household range hoods, sensors with a pressure range of 0-500Pa are usually sufficient.

Anti-oil design

The oil concentration in the fume environment is high, and the sensor should have an anti-oil coating or diaphragm design to ensure long-term stable operation.

Signal output type

Select an output type that is compatible with the range hood control system, such as I2C or 4-20mA.

Design considerations

Installation location optimization:

The sensor should be installed away from locations with high oil concentration to extend its service life.

Data filtering:

Since the airflow in the kitchen environment may fluctuate, it is necessary to introduce a data filtering algorithm into the system to ensure the stability of the monitoring results.

Environmental adaptability design:

Ensure that the sensor can adapt to kitchen environmental factors such as high temperature and humidity.

Висновок

The application of pressure sensors in range hoods has effectively improved the level of intelligent control, and realized functions such as flue blockage detection, automatic wind speed adjustment, and filter cleaning reminders. Through reasonable sensor selection and design optimization, not only can the performance of range hoods be improved, but also a more intelligent and convenient user experience can be provided to users.

WFсенсори діапазон hood related pressure sensors are used in range hoods to accurately sense flue pressure changes. They have obvious performance advantages, can quickly respond to pressure fluctuations, automatically adjust suction, and efficiently exhaust smoke; they have high-precision measurements and accurately reflect flue conditions; they are highly stable, anti-interference, durable and reliable, and improve the use effect and life of range hoods.

Наведене вище введення лише дряпає поверхню застосування технології датчиків тиску. Ми продовжимо досліджувати різні типи сенсорних елементів, які використовуються в різних продуктах, як вони працюють, а також їхні переваги та недоліки. Якщо вам потрібна додаткова інформація про те, що тут обговорюється, ви можете переглянути відповідний вміст далі в цьому посібнику. Якщо у вас немає часу, ви також можете клацнути тут, щоб завантажити докладну інформацію про ці посібники Дані датчика тиску повітря PDF.

Для отримання додаткової інформації про інші сенсорні технології, будь ласка Відвідайте нашу сторінку датчиків.

Very good information. Lucky me I came across your site by chance (stumbleupon).

I’ve book marked it for later!

Good way of describing, and fastidious post to take facts on the

topic of my presentation subject, which i am going

to present in university.

Thank you for another fantastic post. Where else could anybody

get that kind of information in such a perfect means of writing?

I’ve a presentation subsequent week, and I’m at the look for such info.

Great goods from you, man. I’ve remember your stuff prior to and you’re simply

too wonderful. I actually like what you’ve bought right here, really like what you’re saying and the way in which in which

you say it. You make it entertaining and you continue to take care of to stay it wise.

I cant wait to read far more from you. This is actually a terrific website.

Hi there! Someone in my Facebook group shared this site with us so

I came to take a look. I’m definitely enjoying the information. I’m bookmarking and will be

tweeting this to my followers! Fantastic blog and superb

design.

Thanks for another informative website. The place else may

just I am getting that kind of information written in such an ideal way?

I’ve a undertaking that I am just now working on, and I have been at the glance out for

such information.

I like the helpful info you provide in your articles.

I’ll bookmark your blog and check again here regularly.

I am quite sure I will learn many new stuff

right here! Good luck for the next!

Hello, just wanted to mention, I liked this blog post.

It was helpful. Keep on posting!

Great delivery. Sound arguments. Keep up the amazing work.