Temperature Compensation and Calibration Advantages

Compensation Structure Explanation

The die integrates a thick-film resistor network on a ceramic substrate to complete factory zero calibration and wide-range temperature compensation. This approach significantly reduces temperature-induced drift across -40°C to +125°C, lowering field recalibration frequency and improving long-term stability of transmitters in industrial environments.

Impact on Manufacturing and Maintenance

Factory calibration reduces post-production trimming and test workloads for manufacturers, while end users benefit from longer calibration intervals and lower maintenance costs. These gains translate into clear economic and operational advantages for high-volume and high-reliability deployments.

Robust Mechanical Design and Easy Integration

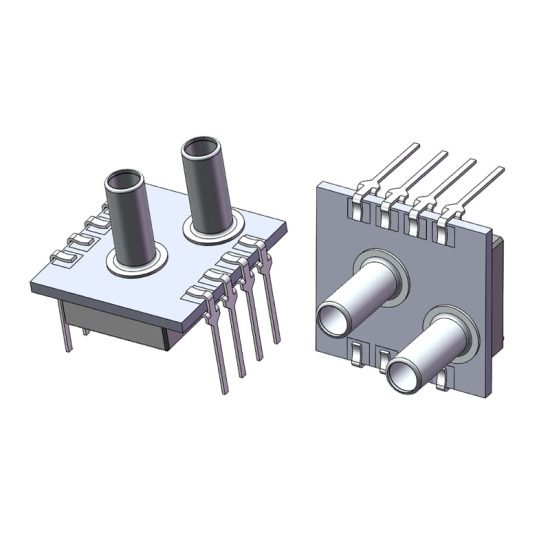

Packaging and Mechanical Strength

The die uses a dual-inline (DIP) package with the sensitive silicon chip mounted on a 1 mm ceramic substrate. This structure offers high overload resistance and effective protection for the silicon element, improving transmitter resistance to shock, vibration and overpressure common in industrial settings.

Assembly and Production Efficiency

The standard DIP form factor allows direct PCB soldering, which simplifies SMT or through-hole assembly steps, shortens production cycles, and reduces labor and rework costs. The compact layout supports modular transmitter designs and cost-controlled mass production.

Accurate Gas Measurement and Wide Applicability

Range and Media Matching

The die is optimized for a 10 kPa range and dry, noncorrosive gases (наприклад, air). That range fits differential measurements on orifices, venturi tubes, and ducts, covering filter monitoring, gas flow measurement, and building HVAC pressure control in industrial and building automation contexts.

Signal Compatibility

Designed for constant-current excitation, the die’s output is compatible with standard amplifier and A/D front ends. This ensures linearity and repeatability, enabling transmitters to maintain consistent calibration processes and stable long-term outputs.

Electrical Matching and Quality Contro

Electrical Design Considerations

To achieve high resolution and low noise, the front end should pair constant-current excitation with low-noise amplification and a high-resolution A/D converter. Proper PCB routing, grounding and filtering maximize die performance and reduce the impact of temperature drift and external interference on readings.

Production Testing and Traceability

Production tests should include zero-drift checks, temperature cycling, long-term aging, and batch traceability records. Integrating these test results into yield analysis helps detect consistency issues early and guides supply-chain and process improvements, ensuring long-term field reliability.

Key Takeaways

Differential-pressure die sensors provide a factory-calibrated, temperature-compensated, mechanically robust, and electrically compatible core for differential-pressure transmitters. With proper mechanical and electrical integration and strict production testing, these dies convert component-level advantages into stronger, more reliable end products. Choosing the right die means choosing stability and accuracy, and it equips a measurement system with dependable core capability.

Наведене вище вступ лише дряпає поверхню застосування технології датчика тиску. Ми продовжуватимемо вивчати різні типи сенсорних елементів, що використовуються в різних продуктах, Як вони працюють, та їх переваги та недоліки. Якщо ви хочете більше детально про те, що тут обговорюється, Ви можете перевірити відповідний вміст пізніше в цьому посібнику. Якщо вас натискають на час, Ви також можете натиснути тут, щоб завантажити деталі цих посібників Дані датчика тиску повітря PDF.

Для отримання додаткової інформації про інші технології датчиків, будь ласка Відвідайте нашу сторінку датчиків.