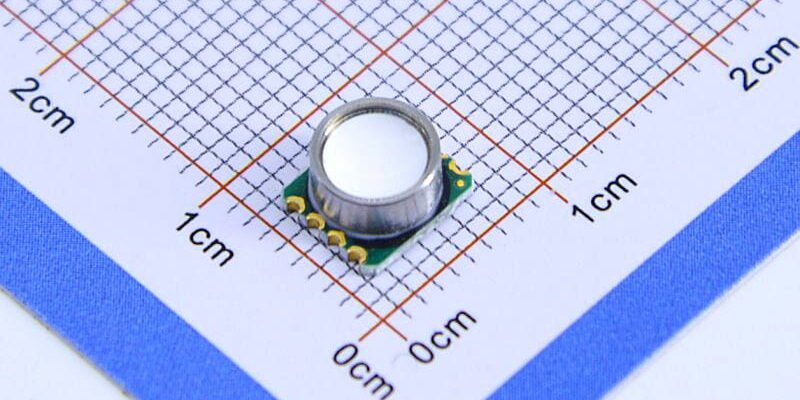

Minyatür Hava Basıncı Sensörünün Çalışma Prensibi ve Kalibrasyon Yöntemi

Min air pressure sensors, because of their high accuracy and small size, are essential to ensure the reliability and measurement accuracy of the sensors. The basic principles of calibration include comparison, range, temperature and long-term stability calibration. The calibration procedure covers preparation, data collection, data processing and record reporting.

Minyatür Hava Basıncı Sensörünün Çalışma Prensibi ve Kalibrasyon Yöntemi Yazıyı Oku »