Diferansiyel basınç sensörleri negatif basınç yara tedavisinde akıllı deneyimi arttırır

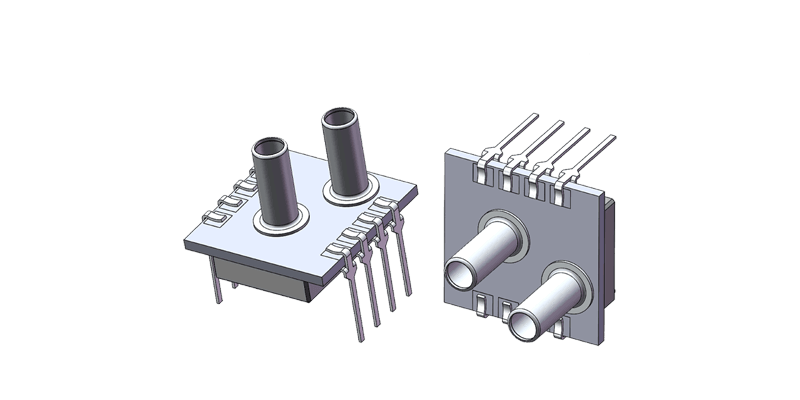

Negative Pressure Wound Therapy (NPWT) as a vital modern medical technology relies directly on precise pressure control for treatment effectiveness. Differential pressure sensors serve as core monitoring components, ensuring treatment safety and efficacy through real-time negative pressure monitoring. This article analyzes the critical role of MEMS differential pressure sensors in NPWT devices, explaining technical principles, application advantages, and significant improvements to patient treatment experience.