The SOP6-package based pressure sensor for nebulizer applications highlights how signal quality and measurement accuracy can be improved by integrating an analog amplified sensor. The sensor used in this nebulizer employs MEMS and ASIC technology and features a wide pressure measurement range (-100 to 350kPa to 1000kPa), temperature compensation, and standard or proportional voltage outputs, making it suitable for monitoring non-corrosive gases. By cooperating with the amplified sensor (analog), the system can effectively enhance the signal processing capability to ensure accurate and stable data output, adapting to the high-precision requirements of atomizers.

Let’s start understanding!

แคตตาล็อก

Product Features Overview

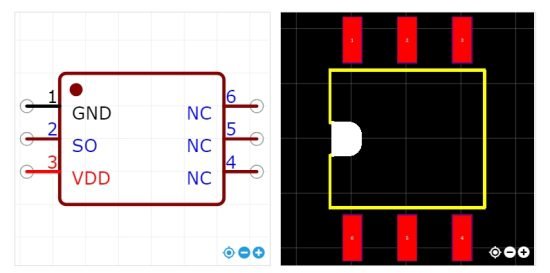

ที่ เซ็นเซอร์ความดัน is packaged in SOP6 package and integrates a MEMS pressure sensitive chip and an ASIC chip. The ASIC chip temperature compensation for parameters such as offset, sensitivity, temperature drift and non-linearity of the pressure sensitive chip, ensuring that a calibrated, temperature compensated standard voltage signal is output at the supply voltage reference. This enables the sensor to maintain a high degree of stability and accuracy in a dynamic operating environment.

product Main features:

Measuring range: -100 ~ 350 kPa, up to 1000 kPa, covering a wide range of application scenarios;

Package: SOP6 package, small size, easy to be integrated into a compact design;

Type: Gauge Pressure, suitable for most of the nebulizers in the monitoring of gas pressure;

Structural design: gas nozzle with an anti-detachment structure, to ensure a solid and long-term reliability of the installation;

Applicable media: Designed for non-corrosive gases, suitable for common atomizing media;

Power supply requirements: 3.3 ~ 5.5 V, suitable for low-power systems;

Output form: standard voltage output or proportional voltage output, easy to match the system and data processing.

Amplified Sensor (Analog) Integration

In order to meet the higher requirements for signal accuracy and dynamic response in nebulizers, an amplified sensor (analog) has been introduced into the system. This module amplifies the signal after the initial weak signal is collected by the sensor and has the following advantages:

Signal Amplification and Filtering

Amplification Sensor (Analog) pre-amplifies the low-amplitude signals from the MEMS chip, and at the same time cooperates with the filtering circuitry to suppress the noise and ensure the stability and accuracy of the data during the subsequent digital conversion.

Temperature Compensation Consistency

Working in conjunction with the internal ASIC compensation algorithm, the amplifier (analog) module ensures that the amplification process does not introduce additional temperature drift errors, so that the output signal always maintains a high degree of linearity and temperature stability.

Standard Voltage Output

The amplified signal is precision-conditioned and output as a standard voltage, providing accurate pressure data for the nebulizer control system and helping to achieve real-time atomization adjustment.

Easy to integrate

The amplification (analog) module uses printed circuit board (PCB) mounting for small size and low power consumption, allowing it to be seamlessly embedded into compact nebulizer designs while efficiently matching the microcontroller and ADC module.

Technology Principles and Compensation Mechanisms

The heart of a pressure sensor is its digital compensation technology. The integrated ASIC chip utilizes internal algorithms to digitally correct the MEMS pressure sensitive element’s intrinsic offset, sensitivity change, temperature drift, and nonlinear error in real time. Using the supply voltage as a reference, the sensor outputs a set of tightly calibrated and temperature-compensated voltage signals, providing reliable and accurate data to support the atomizer control system.

This design not only improves system response speed, but also effectively reduces errors due to ambient temperature changes and fluctuations in operating conditions, providing robust technology for demanding atomization applications.

Advantages of application in nebulizer

1. Precise control of atomization pressure

In nebulizers, gas pressure directly affects the atomization effect. Through the standard voltage signal output from this sensor, the system can monitor and adjust the internal pressure in real time to ensure that the atomized particles are uniform and fine, thus improving the quality of the spray and work efficiency.

2. Wide measurement range

Whether it is a small atomization unit in a low-pressure environment or a large-scale atomization system requiring high-pressure output, the sensor covers a measurement range of -100 ~ 350 kPa to 1000 kPa can meet the design requirements, providing flexible options for a variety of application scenarios.

3. Compact and Highly Integrated

The SOP6 package makes the sensor extremely small, making it easy to fit into the tight spaces of nebulizers. At the same time, the anti-degassing nozzle design ensures that no accidental dislodgement occurs during vibration or long-term operation, ensuring the long-term stability of the system.

4. Low Power Consumption and System Compatibility

The 3.3~5.5V operating voltage design adapts to the needs of modern low-power atomization systems, and with standard or proportional voltage outputs, it is easy to interface seamlessly with microcontrollers and data acquisition modules.

Application Practice and Design Considerations

Environmental Suitability:

Ensure that the gas medium in the nebulizer is a non-corrosive gas to avoid damage to the sensor. If the temperature of the application environment varies greatly, we need to pay attention to the effect of temperature compensation.

Integration design:

In the overall design of the nebulizer, rational planning for the installation of the sensor location, to avoid high humidity, strong vibration areas, to ensure the accuracy of data collection and equipment life.

Power supply matching:

Strictly in accordance with the 3.3 ~ 5.5V power supply requirements for the design of the power supply module, to ensure stable power supply to the system, and reduce the impact of voltage fluctuations.

Output signal processing:

Choose standard voltage or proportional voltage output according to the needs of the control system, the design should be matched with the corresponding signal conditioning and filtering circuits to eliminate interference and improve data accuracy.

บทสรุป

In atomizer applications, the choice of pressure sensor is critical. The high-performance sensor in SOP6 package with integrated MEMS and ASIC compensation technology not only provides accurate pressure data over a wide measurement range, but also ensures system stability in complex operating environments through temperature compensation technology. Through rational design integration and strict process control, the sensor will provide more accurate control and higher operational reliability for the nebulizer, helping intelligent nebulizing equipment to achieve excellent performance.

บทนำข้างต้นเป็นเพียงรอยขีดข่วนบนพื้นผิวของการประยุกต์ใช้เทคโนโลยีเซ็นเซอร์ความดันเท่านั้น เราจะสำรวจองค์ประกอบเซ็นเซอร์ประเภทต่างๆ ที่ใช้ในผลิตภัณฑ์ต่างๆ ต่อไป วิธีทำงาน ตลอดจนข้อดีและข้อเสีย หากคุณต้องการรายละเอียดเพิ่มเติมเกี่ยวกับสิ่งที่กล่าวถึงที่นี่ คุณสามารถดูเนื้อหาที่เกี่ยวข้องได้ในภายหลังในคู่มือนี้ หากคุณมีเวลาจำกัด คุณสามารถคลิกที่นี่เพื่อดาวน์โหลดรายละเอียดของคู่มือนี้ได้ ข้อมูลผลิตภัณฑ์เซ็นเซอร์ความดันอากาศ-

หากต้องการข้อมูลเพิ่มเติมเกี่ยวกับเทคโนโลยีเซ็นเซอร์อื่นๆ โปรด เยี่ยมชมหน้าเซ็นเซอร์ของเรา-