Biological Safety Cabinets (BSC), as important equipment in the laboratory environment, are widely used in the handling of high-risk biological samples. In order to ensure the safety of workers, a vacuum environment needs to be maintained in a biosafety cabinet to prevent the escape of harmful gases or microorganisms. Vacuum pressure sensors play a vital role in this process by monitoring the negative pressure value in real time to ensure the normal operation of the equipment and the safety of the environment.

For engineers, there may be questions:

- What is the importance of vacuum monitoring in biosafety cabinets for laboratory safety?

- How to choose the right pressure sensor for vacuum monitoring?

- How to ensure the accuracy and stability of the vacuum monitoring system?

Let’s start understanding!

แคตตาล็อก

Significance of Vacuum Monitoring in Biological Safety Cabinets

One of the core functions of a biosafety cabinet is to protect the laboratory environment from the spread of hazardous substances through vacuum. Vacuum monitoring is the key to ensure that the internal pressure of the cabinet is lower than the external pressure. Only through a stable vacuum system can we effectively prevent the leakage of germs, viruses, bacteria or chemicals.

Critical role of vacuum monitoring in biosafety cabinets:

Protecting operators from harmful substances

Vacuum monitoring ensures that the air flow inside the biosafety cabinet is always maintained from the outside, preventing harmful substances from leaking outside the laboratory.

Ensure a safe laboratory environment

By monitoring the pressure difference between the inside and outside of the cabinet in real time, changes in pressure can be detected in a timely manner to prevent leakage of hazardous substances due to insufficient vacuum.

Improve equipment reliability and maintenance

Through accurate vacuum monitoring, the operating status of the equipment can be adjusted in real time to improve the efficiency of the equipment and minimize the occurrence of malfunctions.

Common Vacuum Monitoring Methods

Mechanical Pressure Switches

Mechanical pressure switches are often used for basic vacuum monitoring, but their slow response time and limited accuracy make them suitable for applications that do not require high accuracy.

Electronic Pressure Sensors

Electronic pressure sensors provide more accurate pressure data and are suitable for vacuum monitoring in biosafety cabinets where high accuracy is required. They can transmit data to the monitoring system in real time, helping staff to make timely adjustments to the status of the equipment.

Differential Pressure Sensors

Differential Pressure Sensors can simultaneously monitor the pressure difference between the inside and outside of the cabinet, providing a more comprehensive vacuum monitoring solution. Differential pressure sensors are commonly used in environments where high precision is required to ensure that the required vacuum is maintained in the biosafety cabinet at all times.

Components of a vacuum monitoring system

เซ็นเซอร์ความดัน

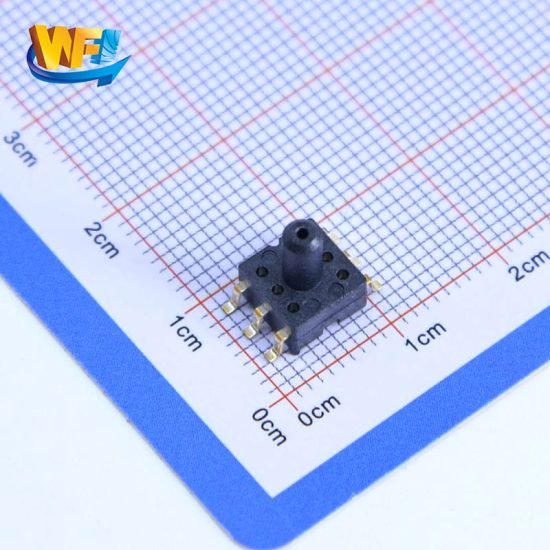

As the core component, WF 100E pressure sensor is responsible for detecting the pressure difference between the inside and outside of the biosafety cabinet in real time and feeding the data back to the control system.

Control System

The control system regulates the vacuum of the biosafety cabinet according to the data from the sensor to ensure a stable working environment.

Alarm system

Once the vacuum value is detected to have deviated from the preset range, the alarm system will immediately send out an alarm to remind the operator to make adjustments.

How to choose the right pressure sensor?

Choosing the right pressure sensor is crucial as it directly affects the accuracy and stability of the vacuum monitoring system. The following are some of the key factors to consider when selecting a pressure sensor:

Range and accuracy

Choose a sensor that fits the vacuum range of the biosafety cabinet, while ensuring that its accuracy meets the laboratorys requirements. A range that is too large or too small may result in inaccurate data.

Corrosion resistance

Hazardous gases and chemicals are often handled in biosafety cabinets, so sensors should have good corrosion resistance to ensure long-term stability.

Response Time

In a laboratory environment, vacuum monitoring requires a quick response to pressure changes, so the response time of the sensor is an important factor to consider when selecting a model.

Compatibility

Selecting sensors that are compatible with existing monitoring systems ensures stable and accurate data transmission.

Maintenance of the vacuum monitoring system

Regular Calibration of Sensors

Pressure sensors are calibrated regularly to ensure accuracy and stability and to avoid data deviation after long-term use.

Cleaning and Maintenance

Keep the sensors and monitoring equipment clean to prevent dust or dirt from affecting the measurement accuracy of the sensors.

Check piping connections

Ensure that all piping connections are secure and free of leaks to avoid affecting the performance of the vacuum monitoring system.

FAQ

Are there any errors in the vacuum monitoring system of a biosafety cabinet?

Under certain circumstances, vacuum monitoring systems may be inaccurate, especially when sensors age or environmental factors change. Therefore, regular calibration and maintenance are important measures to ensure the accuracy of the monitoring system.

Is it necessary to redirect or recalibrate the pressure sensors?

For most biosafety cabinets, pressure sensors do not need to be redirected, but they do need to be calibrated according to the actual situation to ensure their accuracy.

What should I do if there is insufficient vacuum in a biological safety cabinet?

When there is a drop in vacuum, first check that the pressure sensor is functioning correctly. If the sensor is not malfunctioning, check the sealing of the cabinet to ensure that there are no air leaks.

Conclusion:

The vacuum monitoring system of a biosafety cabinet is crucial to laboratory safety. Through proper selection and regular maintenance, pressure sensors can effectively ensure the vacuum status inside a biosafety cabinet, thus preventing the leakage of hazardous substances and protecting the safety of operators. Vacuum monitoring of biosafety cabinets requires not only accurate equipment support, but also sound management and maintenance in order to maximize its effectiveness.