Katalog

Consumer electronics demand for vacuum measurement continues growing, from smartphone barometric sensing to home cleaning device suction control. Modern MEMS technology enables sensors to achieve high-precision measurement within extremely small packages, meeting strict requirements for miniaturization, low power consumption, and high reliability.

1. Core Performance Parameter Requirements

Measurement Range Adaptation for Diverse Applications

Vacuum sensor measurement range directly determines applicability in consumer electronics. Typical applications require coverage from atmospheric pressure to high vacuum levels, usually from -100kPa to near 0 kPa absolute pressure. Different scenarios have varying range requirements.

Resolution and Sensitivity Balance Design

High resolution and excellent sensitivity are key performance indicators for vacuum sensors in consumer electronics applications. Modern MEMS sensors detect minute pressure changes, typically achieving Pa-level resolution for precise vacuum system fluctuation capture.

Precision and Linearity Strict Control

Precision and linearity are key quality indicators for vacuum sensors. Quality sensors typically achieve ±0.35%FS accuracy levels, ensuring measurement errors don’t exceed 0.35% of full scale throughout the entire measurement range.

2. Environmental Adaptability and Material Compatibility

Wide Temperature Range Adaptability

Consumer electronics face complex working environments where temperature variation is a major factor affecting sensor performance. Quality vacuum sensors must maintain stable performance across -40°C to +125°C temperature ranges through precise material selection and structural design.

Medium Compatibility and Protection Design

Sensor material chemical compatibility is crucial for long-term stable operation. Sensors require corrosion-resistant, low-outgassing materials preventing chemical reactions or contamination with measurement medium. IP65-level protection design ensures effective resistance against external dust and liquid intrusion.

Vibration and Shock Resistance

Consumer electronics frequently face vibration and shock challenges, particularly in portable devices and mobile applications. Vacuum sensors must possess excellent vibration and shock resistance, ensuring normal operation under mechanical stress through optimized packaging structure and shock-absorbing design.

3. Signal Interface and System Integration

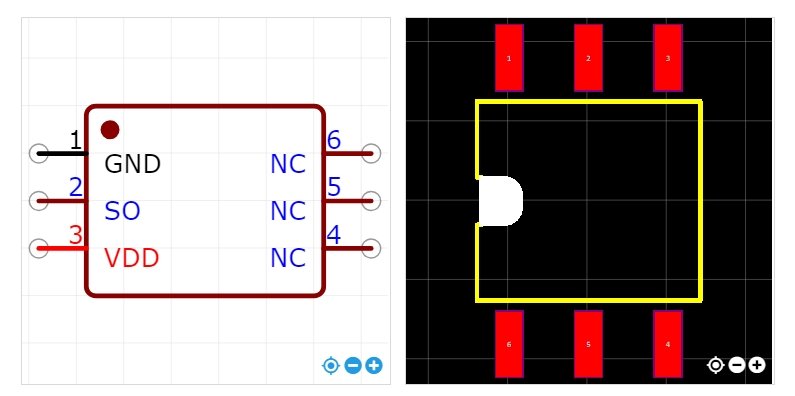

Diversified Electrical Interface Options

Modern vacuum sensors offer multiple electrical interface options to adapt to different system integration requirements. Analog output interfaces typically use 0-10V or mV-level voltage signals suitable for traditional analog control systems. Digital interfaces like I2C and SPI provide convenient communication methods for modern microcontroller systems.

Dynamic Response Time Optimization

Fast response time is an important characteristic for vacuum sensors in dynamic applications. Sensors must quickly track pressure changes in vacuum systems, providing real-time feedback for control systems. Modern MEMS sensors achieve millisecond-level response times through optimized structural design and signal processing algorithms.

4. Reliability and Maintenance Characteristics

Long-term Stability Assurance

Consumer electronics have strict requirements for sensor long-term stability. Quality vacuum sensors ensure stable performance during extended use through precise manufacturing processes and strict quality control. Repeatability error and long-term drift are key indicators for evaluating sensor stability.

Calibration and Maintenance Convenience

Modern vacuum sensor design considers calibration and maintenance convenience. Field calibration support enables sensors to adjust precision in actual operating environments, adapting to different working conditions. Temperature calibration ensures measurement accuracy across different geographical locations and environmental conditions.

5. Technical Development Trends and Application Prospects

Miniaturization and Integration Development

As consumer electronics develop toward miniaturization, vacuum sensors continuously reduce size while improving integration. New generation MEMS sensors adopt advanced manufacturing processes, achieving smaller package sizes while maintaining high performance.

Intelligence and Networking Features

Modern vacuum sensors are developing toward intelligence, integrating more signal processing and communication functions. Built-in microprocessors enable complex data processing and diagnostic functions, improving system intelligence levels.

Slutsats

Vacuum sensor applications in consumer electronics continue deepening, with technical development showing high-precision, miniaturization, and intelligence trends. From precise measurement range matching to comprehensive environmental adaptability consideration, from diversified signal interface selection to long-term reliability assurance, every technical detail directly affects final product performance. Engineers and technical decision-makers must comprehensively consider application requirements, environmental conditions, and system architecture during selection processes.

Ovanstående introduktion repar bara ytan på tillämpningarna av trycksensorteknologi. Vi kommer att fortsätta att utforska de olika typerna av sensorelement som används i olika produkter, hur de fungerar och deras fördelar och nackdelar. Om du vill ha mer information om vad som diskuteras här kan du kolla in det relaterade innehållet längre fram i den här guiden. Om du är tidspressad kan du också klicka här för att ladda ner detaljerna i denna guide Lufttryckssensor Produkt PDF -data.

För mer information om andra sensorteknologier, vänligen Besök vår Sensors -sida.