Katalog

Modern water meter systems increasingly demand precise pressure monitoring, with MEMS-manufactured miniaturized pressure sensors becoming the core technical solution. These sensors achieve complete calibration of range, sensitivity, and temperature compensation through advanced microelectromechanical systems processes, providing an ideal technology platform for water meter integration. This article analyzes the technical characteristics, integration advantages, and practical application effects of MEMS pressure sensors in water meter applications.

1. Technical Foundation of MEMS Pressure Sensors

1.1 Microelectromechanical Systems Manufacturing Process

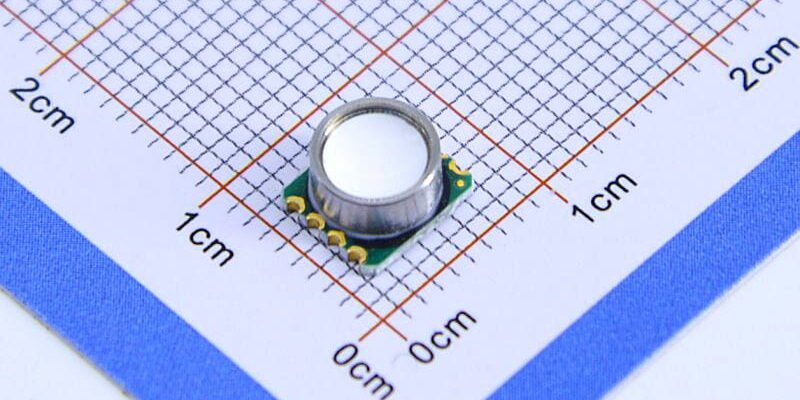

MEMS pressure sensors utilize silicon-based micromachining technology, manufactured through precise lithography, etching, and thin-film deposition processes. The sensor chip size typically ranges within several millimeters, effectively responding to pressure changes and generating corresponding electrical signal outputs. This manufacturing process ensures excellent consistency and reliability while significantly reducing production costs. The inherent characteristics of silicon-based materials allow sensors to maintain stable performance over extended use, particularly in water meter applications requiring continuous monitoring.

1.2 Sensor Structure Design Features

Modern MEMS pressure sensors typically employ diaphragm-based structural designs, with the core sensing element being a silicon diaphragm. When external pressure acts, the diaphragm undergoes minute deformation, converting mechanical deformation into resistance changes through integrated piezoresistive elements. The sensor packaging uses miniaturized design with standardized electrical interfaces, facilitating integration with water meter circuit systems. This structural design ensures high-precision pressure measurement while providing good media compatibility, allowing direct contact with water media without affecting measurement accuracy.

2. Technical Advantages of Water Meter Integration

2.1 Mini Integration Benefits

The miniaturization characteristics of MEMS pressure sensors enable seamless integration within the limited space of water meter internals. The compact sensor design doesn’t affect the overall water meter structure and water flow channels while providing flexible installation options. This integration approach achieves precise collection of temperature, pressure, flow velocity, and flow rate information for pipeline domestic water, providing reliable data support for pipeline network leakage detection and location. Miniaturized design also reduces water meter manufacturing costs and complexity, improving product market competitiveness.

2.2 Precision and Stability Assurance

MEMS pressure sensors integrated within water meters undergo complete calibration, including precise adjustment of range, offset, and nonlinearity characteristics. The sensors possess excellent repeatability, linearity, and long-term stability, maintaining consistent measurement accuracy under different operating conditions. This high-precision characteristic enables sensors to accurately monitor and record pressure pipeline water pressure changes, meeting strict requirements for water supply and drainage construction sites and related pressure pipeline water pressure testing.

2.3 Temperature Compensation Technology Implementation

MEMS pressure sensors incorporate built-in temperature compensation functionality, eliminating temperature change effects on measurement accuracy through combined hardware and software approaches. Sensors undergo multi-point temperature calibration before factory shipment, establishing precise temperature compensation models. This compensation technology ensures sensor stability across wide temperature ranges, particularly suitable for outdoor water meter applications facing temperature variation challenges.

3. Smart Water Meter System Integration Solutions

3.1 Signal Processing and Data Transmission

Integrated MEMS pressure sensors directly connect to water meter electronic control units, enabling real-time pressure signal processing and data transmission. Sensor analog outputs undergo amplification, filtering, and digitization processing, converting to standard digital signal formats. This integration solution supports multiple communication protocols, facilitating connection with host systems and IoT platforms. Sensors can receive control signals from water meters while providing real-time pressure monitoring data to systems, achieving bidirectional communication functionality.

3.2 Automated Control Functions

When pressure sensors electrically connect to electric pressure pumps, systems can automatically control pump startup and shutdown based on monitored water pressure and preset test pressure. This automated control functionality significantly improves water pressure testing efficiency and accuracy, reducing human operation errors. The sensor’s rapid response characteristics ensure control system real-time performance, enabling timely response to pressure changes and executing corresponding control actions.

3.3 Fault Diagnosis and Early Warning

Integrated pressure sensors possess self-diagnostic capabilities, detecting sensor operational status and measurement system abnormalities. When detecting pressure abnormalities, sensor failures, or system communication interruptions, systems automatically trigger warning mechanisms, notifying operators through displays or remote communication methods. This intelligent fault diagnosis functionality improves water meter system reliability and maintenance efficiency.

4. Practical Application Effect Analysis

4.1 Pipeline Network Leakage Detection Capability

Smart water meters with integrated MEMS pressure sensors can monitor pipeline pressure changes in real-time, identifying pipeline network leakage conditions through pressure fluctuation pattern analysis. The sensor’s high sensitivity characteristics enable detection of minute pressure changes, providing technical support for early leakage discovery. This detection capability effectively solves technical challenges in small-diameter pipeline network leakage analysis for water distribution systems, improving water supply system operational efficiency.

4.2 Multi-parameter Comprehensive Monitoring

Modern water meter systems achieve comprehensive monitoring of temperature, pressure, flow velocity, and flow rate through integrated multiple sensors. MEMS pressure sensors, as core components, work synergistically with other sensors to provide comprehensive water quality and quantity monitoring data. This multi-parameter monitoring capability provides more comprehensive and accurate information support for water supply management, helping optimize water supply system operational strategies.

4.3 Commercial Application Prospects

The technological maturity and cost advantages of MEMS pressure sensors enable widespread application in water meters, industrial control, commercial gas meters, small appliance pressure applications, and laser equipment fields. With IoT technology development and smart city construction advancement, smart water meters with integrated pressure sensors will become important components of urban infrastructure, with very broad market prospects.

5. Technology Development Trends

5.1 Integration Enhancement

Future MEMS pressure sensors will develop toward higher integration levels, integrating multiple sensing functions like pressure, temperature, and humidity on single chips. This system-level integration approach will further reduce sensor size, lower costs, and improve overall system performance. Simultaneously, integrated signal processing circuits will possess stronger computational capabilities, supporting more complex data analysis and processing algorithms.

5.2 Enhanced Intelligence Functions

Next-generation MEMS pressure sensors will possess stronger intelligence functions, including adaptive calibration, machine learning algorithms, and predictive maintenance. These functions will enable sensors to autonomously learn and adapt to different working environments, providing more accurate and reliable measurement results. Enhanced intelligence functions will further improve water meter system automation levels and operational efficiency.

5.3 Communication Technology Integration

With the development of next-generation communication technologies like 5G, NB-IoT, and LoRaWAN, MEMS pressure sensors will possess stronger wireless communication capabilities. This communication technology integration will enable water meter systems to achieve more flexible and efficient data transmission, supporting large-scale IoT applications.

Slutsats

Mini MEMS pressure sensors integrated within water meters represent an important development direction for modern water meter technology. These sensors achieve high-precision, high-stability, and high-reliability pressure measurement functions through advanced microelectromechanical systems manufacturing processes. Complete calibration of range, offset, and nonlinearity characteristics, combined with advanced temperature compensation technology, ensures excellent sensor performance under various operating conditions. Miniaturized design enables seamless sensor integration within water meter internals, providing core technical support for smart water meter systems. With continuous technological development, these sensors will play increasingly important roles in smart city construction and water supply management modernization processes.

Ovanstående introduktion repor bara ytan på tillämpningarna av trycksensorteknologi. Vi kommer att fortsätta utforska de olika typerna av sensorelement som används i olika produkter, Hur de arbetar, och deras fördelar och nackdelar. Om du vill ha mer detaljer om vad som diskuteras här, Du kan kolla in det relaterade innehållet senare i den här guiden. Om du är pressad i tid, Du kan också klicka här för att ladda ner detaljerna i dessa guider Lufttryckssensor Produkt PDF -data.

För mer information om andra sensorteknologier, behaga Besök vår Sensors -sida.