Katalog

MEMS pressure sensors are redefining intelligent standards in instrumentation through microelectromechanical systems technology, achieving unprecedented measurement accuracy and response speed.

1. Intelligent Breakthrough in Pressure Range and Accuracy

Full-Range Dynamic Adaptation Technology

MEMS pressure sensors demonstrate intelligence through wide pressure range coverage from 0.1kPa to 10MPa. Dynamic adaptation enables instruments to automatically adjust measurement ranges without manual intervention, significantly improving monitoring continuity and reliability.

Relative Accuracy and Resolution Optimization

Intelligent processing of relative accuracy represents the core advantage of MEMS sensors. Built-in temperature compensation algorithms and nonlinear correction ensure stable relative accuracy under different environmental conditions.

2. Temperature Compensation and Working Environment Adaptability

Intelligent Temperature Compensation Mechanism

Temperature compensation functionality is key technology for intelligent monitoring. Built-in temperature sensing elements monitor environmental temperature changes in real-time, automatically adjusting pressure measurements through digital signal processing chips.

Working Voltage Intelligent Management

Intelligent voltage management allows MEMS sensors to adapt to different power supply environments. Wide voltage operation from 3.3V to 5V, combined with low power design, enables instruments to work normally under battery power or unstable power conditions.

3. Response Speed and Noise Control Technology

High-Speed Response and Real-Time Processing

Fast response characteristics of MEMS pressure sensors provide important foundation for intelligent monitoring. Millisecond-level response time enables instruments to track pressure changes in real-time, crucial for dynamic process monitoring.

Noise Suppression and Signal Optimization

Low noise characteristics represent important manifestation of MEMS sensor intelligence. Advanced signal processing technology controls noise levels within extremely low ranges, ensuring measurement data reliability.

4. Wide Pressure and Bidirectional Pressure Monitoring

Wide Pressure Range Intelligent Recognition

Wide pressure monitoring capability allows MEMS sensors to handle full-range pressure measurement from vacuum to high pressure. Intelligent recognition algorithms automatically judge current pressure states and adjust measurement parameters.

Positive and Negative Pressure Bidirectional Monitoring

Bidirectional monitoring of positive and negative pressure is an important feature of MEMS sensor intelligence. Sensors accurately distinguish pressure directions and provide corresponding measurement data.

5. Digital Integration and Intelligent Decision Making

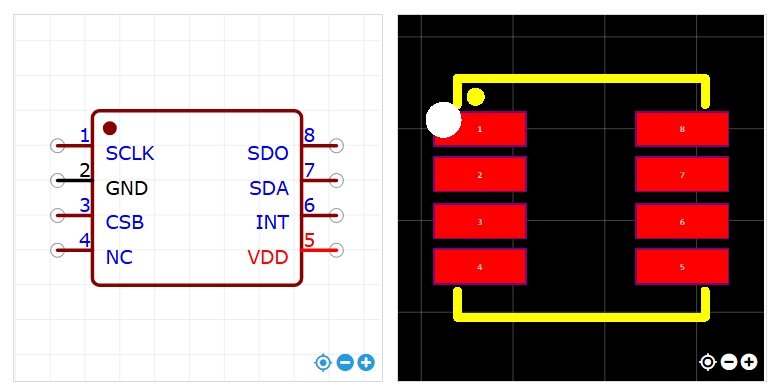

Digital Interface and System Integration

Digital interface design of MEMS pressure sensors enables easy integration into modern intelligent instrument systems. Through I2C, SPI standard communication protocols, sensors connect directly with microcontrollers.

Intelligent Algorithms and Predictive Analysis

Integrated intelligent algorithms enable MEMS sensors to provide real-time pressure data and perform trend analysis and anomaly detection. Machine learning algorithms learn normal working mode pressure characteristics.

Slutsats

MEMS pressure sensors are driving instrumentation monitoring technology to higher levels through excellent technical characteristics and intelligent functions. These technological advances not only improve measurement accuracy and reliability but provide solid technical foundation for intelligent manufacturing in Industry 4.0 era.

Ovanstående introduktion repar bara ytan på tillämpningarna av trycksensorteknologi. Vi kommer att fortsätta att utforska de olika typerna av sensorelement som används i olika produkter, hur de fungerar och deras fördelar och nackdelar. Om du vill ha mer information om vad som diskuteras här kan du kolla in det relaterade innehållet längre fram i den här guiden. Om du är tidspressad kan du också klicka här för att ladda ner detaljerna i denna guide Lufttryckssensor Produkt PDF -data.

För mer information om andra sensorteknologier, vänligen Besök vår Sensors -sida.