Katalog

Invasive blood pressure sensors serve as core technology in modern medical monitoring, playing an irreplaceable role in vital sign surveillance for critically ill patients. This article provides in-depth analysis of MEMS-based silicon piezoresistive pressure sensors’ application value in hemodynamic monitoring, focusing on technical principles, performance characteristics, and clinical implementation solutions.

1. Silicon Piezoresistive Sensor Technology Core

Piezoresistive Effect Mechanism

Silicon piezoresistive pressure sensors utilize unique physical properties where silicon material resistance changes predictably under mechanical stress. The sensor employs single-crystal silicon wafers and Wheatstone bridge configuration.

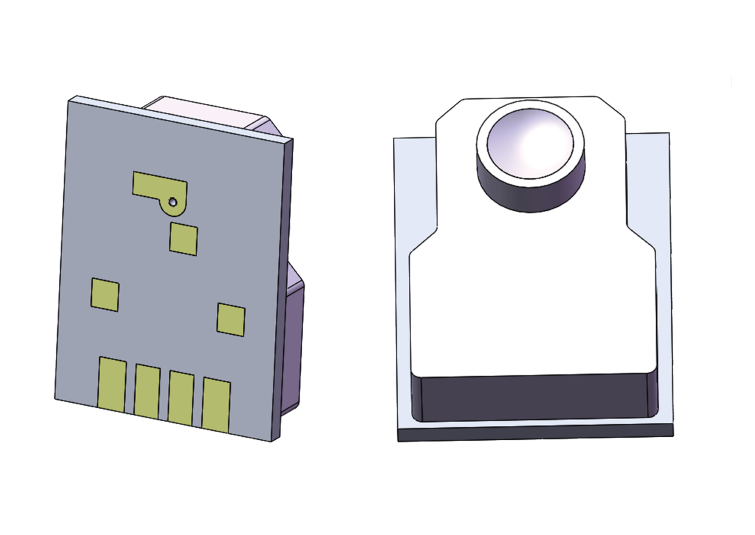

Sensor Structure Design Features

Modern invasive blood pressure sensors use ceramic substrate packaging technology, providing mechanical stability and excellent temperature characteristics. Protective gel layers effectively isolate contaminants while maintaining pressure transmission accuracy.

Signal Processing and Compensation Technology

Integrated thick-film circuits provide signal amplification, temperature compensation, and linearization processing. Using supply voltage as reference, the system outputs standardized voltage signals, ensuring stable measurement accuracy within 15℃-40℃ operating range.

2. Medical Application Performance Advantages

Measurement Accuracy and Reliability

Compared to traditional strain-gauge sensors, silicon piezoresistive sensors demonstrate superior sensitivity, detecting minute pressure changes within -50 to 300mmHg range. Excellent linearity reduces backend signal processing complexity.

Real-time Response Characteristics

Invasive blood pressure monitoring requires rapid sensor response to capture instantaneous pressure changes. Silicon piezoresistive sensors’ miniaturized structure design enables extremely short response times for real-time arterial pressure tracking.

Biocompatibility Design

Medical-grade invasive sensors must meet strict biosafety requirements. Sensors manufactured with medical-grade materials feature surface treatments compliant with biocompatibility standards, designed for single-use with 168-hour continuous operation capability.

3. Clinical Monitoring Solution Implementation

Hemodynamic Parameter Acquisition

Invasive blood pressure monitoring systems place sensors directly into arteries via catheters, establishing connections between vessels and monitoring equipment. Sensors detect real-time intravascular pressure changes.

Multi-parameter Comprehensive Monitoring

Modern systems extend beyond pressure measurement, obtaining cardiac output, peripheral resistance, and vascular compliance through waveform analysis. High-precision pressure data provides reliable foundation for derived parameter calculations.

Automated Integration Applications

Sensor design considers automated production requirements, with standardized packaging forms facilitating mechanical batch assembly. This approach reduces manufacturing costs while improving product consistency and reliability.

4. Technical Specifications and Performance Indicators

Core Technical Parameters

Technical specifications strictly follow AAMI blood pressure monitor standards. Pressure measurement range covers -50 to 300mmHg, fully meeting clinical monitoring requirements within 15℃-40℃ operating temperatures.

Electrical Performance Characteristics

Sensors utilize standard power supply methods with voltage signal outputs, facilitating interface compatibility with various monitoring devices. Low-power design extends operating time while excellent electromagnetic compatibility ensures stable operation.

Mechanical Strength Design

Ceramic substrate selection provides superior insulation and mechanical strength. Sensors withstand various mechanical stresses during transportation, installation, and use while maintaining long-term stable performance.

5. Quality Control and Standards Compliance

Medical Device Standards Adherence

Product development strictly follows international medical device standards including ISO 13485 quality management and ISO 14971 risk management. Comprehensive quality control measures ensure consistency and reliability.

Calibration and Verification Procedures

Each sensor undergoes rigorous calibration and verification before shipment. Multi-point calibration using standard pressure sources ensures accuracy compliance across entire measurement ranges.

Traceability Management

Comprehensive product traceability systems maintain detailed records from raw materials to end users, satisfying medical device regulatory requirements while supporting rapid quality issue resolution.

Slutsats

Invasive blood pressure sensors represent essential components of modern medical monitoring technology. MEMS-based silicon piezoresistive designs provide reliable solutions for clinical hemodynamic monitoring with superior measurement accuracy, real-time response, and biocompatibility, making them ideal choices for critical patient monitoring and surgical surveillance.

Ovanstående introduktion repar bara ytan på tillämpningarna av trycksensorteknologi. Vi kommer att fortsätta att utforska de olika typerna av sensorelement som används i olika produkter, hur de fungerar och deras fördelar och nackdelar. Om du vill ha mer information om vad som diskuteras här kan du kolla in det relaterade innehållet längre fram i den här guiden. Om du är tidspressad kan du också klicka här för att ladda ner detaljerna i denna guide Lufttryckssensor Produkt PDF -data.

För mer information om andra sensorteknologier, vänligen Besök vår Sensors -sida.