Katalog

Digital pressure sensors play a crucial role in improving power meter detection accuracy. By adopting high-sensitivity MEMS chip technology, combined with precision digital temperature compensation and nonlinear correction techniques, modern digital pressure sensors achieve higher measurement precision and long-term stability. This article focuses on analyzing the technical advantages of high-sensitivity chips in power meter applications, including I2C/SPI interface protocol support, anti-vibration design, and flush-mount maintenance-free characteristics.

1. Core Advantages of High-Sensitivity Chip Technology

Precision Breakthrough of Piezoresistive MEMS Chips

High-sensitivity pressure sensor chips employ advanced piezoresistive MEMS technology, achieving precise conversion from pressure to electrical signals through silicon material’s piezoresistive effect. This technology can achieve sensitivity of up to 0.003 kHz/MPa within extremely small chip dimensions, equivalent to approximately 30 ppm/MPa precision level. The integrated Wheatstone bridge design within the chip places four high-precision semiconductor strain gauges at maximum stress points, ensuring measurement linearity and repeatability. Compared to traditional analog sensors, digital chips directly output calibrated digital signals, eliminating noise interference during analog signal transmission.

Temperature Compensation and Nonlinear Correction Technology

Precision digital temperature compensation is a key feature of high-sensitivity chips. The chip integrates a 24-bit high-precision ADC capable of simultaneously measuring pressure and temperature, performing real-time compensation for sensor output offset, sensitivity, and temperature drift through internal calibration logic. Nonlinear correction technology controls sensor nonlinear errors within ±0.1% through polynomial fitting algorithms. This dual correction mechanism ensures measurement accuracy across wide temperature ranges, particularly suitable for long-term stable operation of power meters in outdoor environments.

2. Digital Interface Protocols and System Integration

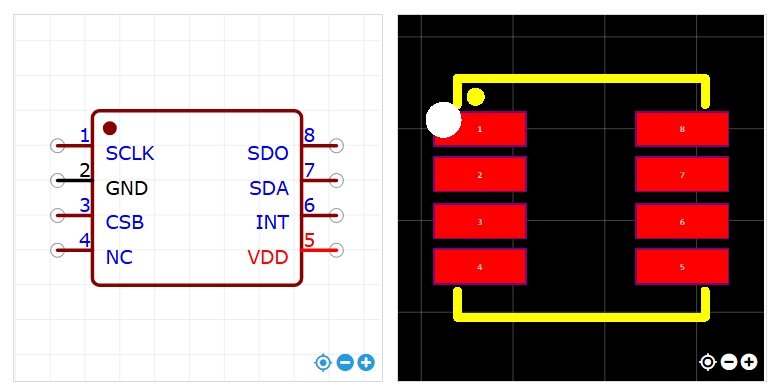

Technical Advantages of I2C and SPI Interfaces

Modern digital pressure sensors support both I2C and SPI interface protocols, providing flexible integration options for power meter systems. I2C interface adopts two-wire design, saving PCB routing space and suitable for multi-sensor system bus connections. SPI interface supports higher data transmission rates, enabling rapid pressure data acquisition. 14-bit digital output resolution ensures pressure measurement precision, meeting power meters’ strict accuracy requirements. Digital interface characteristics eliminate temperature drift and noise issues of analog signals, improving overall system reliability.

Sampling Rate and Response Time Optimization

High-sensitivity chip sampling rate design directly affects power meter detection accuracy. Modern digital pressure sensors achieve sampling rates up to 1000Hz, ensuring rapid response to pressure changes. Low-latency digital signal processing algorithms reduce sensor response time to millisecond levels, crucial for real-time power meter monitoring. Fast response characteristics combined with high-resolution output enable sensors to capture minute pressure changes, thus improving power meter detection accuracy under different load conditions.

3. Anti-Interference Design and Environmental Adaptability

Anti-Vibration and Mechanical Stability

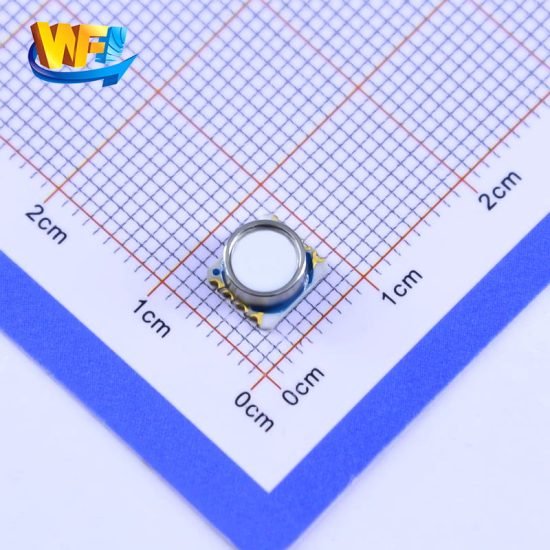

Power meters face various mechanical vibrations and impacts in practical applications. High-sensitivity chips employ specialized anti-vibration designs. Chip packaging uses LGA (Land Grid Array) form, achieving stable mechanical connections through eight symmetrically distributed gold-plated contact points. Protective membrane design not only protects internal MEMS structures but also provides excellent impact resistance. This design ensures sensors maintain stable detection accuracy in vibration environments generated by power equipment operation, avoiding measurement errors caused by mechanical stress.

High-Temperature Resistance and Long-Term Stability

High-sensitivity chips’ high-temperature resistance is a significant advantage in power meter applications. Chips operate stably across -40°C to 85°C wide temperature ranges, meeting power meter usage requirements under various environmental conditions. Long-term stability design through optimized silicon material crystal structure and packaging processes ensures sensor performance doesn’t degrade during extended use. Anti-corrosion materials further improve sensor reliability in harsh environments, extending power meter service life.

4. Flush-Mount Structure and Maintenance-Free Design

Practical Advantages of Flush Detection Areas

Digital pressure sensors adopt flush-mount structure design, keeping detection areas flush with installation surfaces, effectively avoiding clogging issues common in traditional sensors. This design particularly suits power meters’ long-term maintenance-free operation requirements. Flush structures reduce dust and debris accumulation at detection areas, maintaining long-term stability of sensor detection accuracy. Simultaneously, flush design simplifies installation processes, reducing power meter manufacturing and maintenance costs.

Vacuum and Absolute Pressure Measurement Capabilities

High-sensitivity chips support vacuum and absolute pressure range measurements, covering wide ranges from 0 to 2MPa. This wide-range design enables single sensors to adapt to power meter pressure detection needs under different operating conditions. Absolute pressure measurement capability ensures sensors aren’t affected by atmospheric pressure changes, providing more accurate and stable pressure readings. Multi-range coverage reduces power meter design complexity and lowers system costs.

5. Display Accuracy and Data Processing Capabilities

High-Precision Digital Output Characteristics

Digital pressure sensor display accuracy directly determines power meter detection accuracy levels. High-sensitivity chips achieve excellent stability and linearity through internally integrated high-precision ADCs and digital signal processors. 14-bit digital output provides sufficient resolution to detect minute pressure changes. Low temperature drift characteristics ensure measurement consistency across different temperature conditions, crucial for long-term accurate power meter operation.

Data Processing Algorithm Optimization

Advanced data processing algorithms are core technologies of high-sensitivity chips. Chip-integrated calibration logic automatically performs zero-point offset and full-scale calibration without external calibration steps. Real-time filtering algorithms effectively suppress environmental noise effects on measurement accuracy. Multi-point calibration technology stores calibration coefficients for multiple temperature points, achieving precise measurement across full temperature ranges. These algorithm optimizations enable power meters to maintain high detection accuracy under various operating conditions.

Slutsats

Digital pressure sensors using high-sensitivity chip technology significantly enhance power meter detection accuracy. Through integration of piezoresistive MEMS technology, precision digital temperature compensation, I2C/SPI interface support, and anti-vibration design, modern digital pressure sensors achieve high precision, stability, and long-term maintenance-free performance goals. Flush-mount structure design and wide-range measurement capabilities further enhance sensor practicality in power meter applications. These technological advances not only improve power meter detection accuracy but also provide reliable technical support for power system intelligent upgrades.

Ovanstående introduktion repar bara ytan på tillämpningarna av trycksensorteknologi. Vi kommer att fortsätta att utforska de olika typerna av sensorelement som används i olika produkter, hur de fungerar och deras fördelar och nackdelar. Om du vill ha mer information om vad som diskuteras här kan du kolla in det relaterade innehållet längre fram i den här guiden. Om du är tidspressad kan du också klicka här för att ladda ner detaljerna i denna guide Lufttryckssensor Produkt PDF -data.

För mer information om andra sensorteknologier, vänligen Besök vår Sensors -sida.