Katalog

Under the backdrop of rapidly growing market demand for electronic control systems in vehicles (as illustrated), automotive sensor technology continues to advance. The overall trends for future automotive sensors include:

Intelligence: Sensors with on-board processing and decision-making capabilities.

Miniaturization: Smaller form factors for easier integration and lower cost.

Integration: Combining multiple sensing functions or electronics into a single package.

Multifunctionality: One device measuring several physical parameters.

New Materials & Processes: Novel sensor structures enabled by advanced materials and manufacturing techniques.

MEMS-based sensors have become the core components in modern automotive sensing.

Classification of Automotive Sensors

Based on system context and function, automotive sensors can be grouped into:

Powertrain Control System MEMS

Body Electronics System MEMS

Safety Electronics System MEMS

ADAS (Advanced Driver-Assistance System) MEMS

1. Powertrain Control System MEMS

Air Mass Flow Meter – intake control

Knock Sensor – engine management

Ride-Height Sensor – suspension control

Smart Battery Sensor – battery management

Oxygen Sensor – exhaust emission monitoring and control

Pedal Position Sensor – start-stop / auto-hold functions

Angle & Position Sensors – engine control / steering control

Trycksensorer – engine, transmission, turbocharger, and fuel-injection control

2. Body Electronics System MEMS

Ambient Light Sensor – automatic headlamp control

Window Lift Speed Sensor – pinch-guard for power windows

Rain Sensor – automatic windshield wipers

Trycksensorer – central locking system

Air Quality Sensor – HVAC air intake

Temperature Sensor – HVAC

Humidity Sensor – HVAC

3. Safety Electronics System MEMS

High-Pressure Sensor – ESC (Electronic Stability Control)

Steering-Wheel Angle Sensor – ESC

Accelerometer – airbags / ABS

Seat Occupancy Sensor – airbags

Gyro (Yaw-Rate) Sensor – airbags

Wheel Speed Sensor – ABS

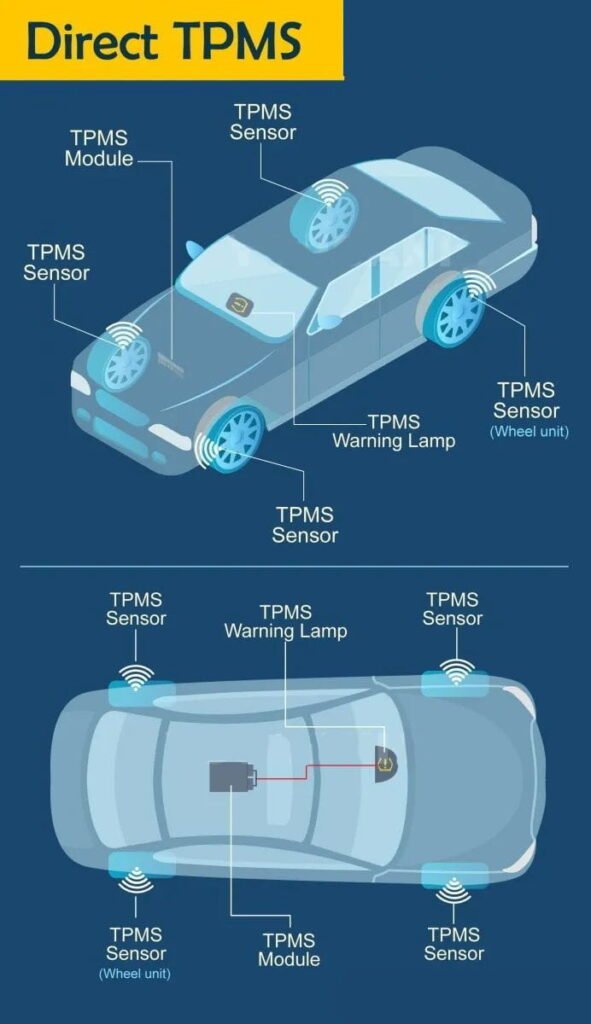

Trycksensor – TPMS (Tire-Pressure Monitoring System)

Temperature Sensor – TPMS

4. ADAS MEMS

CMOS Image Sensor – lane-keeping / 360° surround view

Long-Range Millimeter-Wave Radar – adaptive cruise control / collision warning

LiDAR – collision warning / autonomous driving

Short-Range Millimeter-Wave Radar – blind-spot assist

Ultrasonic Sensor – parking aid

Infrared Sensor – night vision

Applications of Automotive MEMS

The automotive market is a major application field for sensors. MEMS automotive sensors serve as critical information sources for vehicle electronic control systems, providing real-time, accurate measurements of temperature, pressure, position, speed, acceleration, vibration, and more. A typical family sedan now carries nearly 100 sensors; luxury vehicles can have up to 200.

Beyond MEMS, the automotive sensor market includes classic active sensors such as odometer sensors, intake/oil pressure sensors, coolant-temperature sensors, air-flow meters, TPMS sensors, chemical sensors, inertial sensors, magnetic sensors, ultrasonic sensors, image sensors, radar, and LiDAR.

Key Sensor Types and Functions

Odometer (Mileage) Sensor

Principle: Hall-effect or photoelectric detection.

Function: Calculates vehicle speed and distance using wheel/axle rotational speed (ω) and known tire radius (r):

Distance=r×ω×t.

Design: Gear-drive style with two bearings on the driveshaft, reducing torque and friction. Connector sits on the transmission housing.

Intake-Manifold Pressure Sensor

Function: Measures absolute pressure in the intake manifold, outputs voltage to ECU to determine base fuel injection quantity.

Common Types: Semiconductor piezoresistive sensors.

Ansökningar: Used on vehicles such as the Audi 100 (V6 engine), Santana 2000, Jeep Cherokee 2.5 L, Toyota Crown 3.0 L, etc.

Oil-Pressure Sensor

Function: Monitors engine oil pressure, signals the driver when oil pressure falls below safe levels.

Types: Silicon piezoresistive and silicon-capacitive MEMS sensors, integrating sensing element, signal conditioning, and interface electronics.

Coolant-Temperature Sensor

Internal Element: Semiconductor thermistor—resistance decreases as temperature rises.

Location: Installed in engine block or cylinder-head water jacket.

Role: Provides ECU with coolant-temperature data for fuel-injection and ignition timing corrections.

Air-Flow Sensor (MAF)

Function: Converts intake-air mass or volume flow into an electrical signal for the ECU’s fuel-injection calculation.

Types:

Vane-type (e.g., Toyota Previa),

Vortex-shedding (e.g., Lexus LS400),

Hot-wire (e.g., Nissan Sunny VG30E),

Hot-film (volumetric and mass-flow models).

ABS Wheel-Speed Sensor

Location: Mounted on brake caliper near the rotor.

Principle: Inductive coil senses a toothed tone ring on the wheel hub; generates a quasi-sine AC signal proportional to wheel speed, sent to the ABS ECU.

Airbag Crash (Impact) Sensor

Types:

Trigger Sensors: Detect rapid deceleration during collision and initiate airbag deployment.

Safing Sensors: Prevent false deployment in non-collision events.

Technologies: Resonant-type and non-resonant accelerometers (piezoelectric or magnetostrictive).

Exhaust-Gas Oxygen Sensor

Purpose: Measures O₂ concentration in exhaust to control the air-fuel ratio.

Variants:

Zirconia ceramic sensor (–40 °C to 900 °C, ±1% accuracy),

Zirconia concentration-cell sensor (300 °C to 800 °C),

Solid-electrolyte oxygen sensor (0 °C to 400 °C, ±0.5% accuracy),

TiO₂ semiconductor sensor (robust against lead contamination).

Position & Speed Sensors

Functions: Monitor crankshaft/camshaft angles, throttle position, vehicle speed, acceleration/deceleration.

Types: Alternator-type, magnetoresistive, Hall-effect, reed-switch, optical, and transistor-magnetic sensors.

Throttle-Position Sensor: Detects throttle-plate angle via mechanical linkage—switch, variable-resistor, or integrated designs.

Crankshaft Position Sensor: Provides top-dead-center, crank angle, and speed signals. Types include inductive, Hall-effect, and optical variants.

Knock Sensor: Mounted on engine block to detect knock via vibration—magnetostrictive or piezoelectric.

Vehicle Speed & Motor RPM Sensors (EV)

Motor RPM Sensor: Inductive, optical, or Hall-effect, non-contact measurement for safety and precision.

Vehicle-Speed Sensor: Electromagnetic, optical, variable-reluctance, or Hall-effect to measure driving speed.

Market Overview

The automotive sensor segment has become a major application area for MEMS devices. Pressure sensors, accelerometers, gyroscopes, and flow sensors together represent 99% of automotive MEMS applications, with five-year growth rates of 3–12%. MEMS pressure sensors are the most widely used, priced around $5–7 each. In 2018, automotive MEMS pressure-sensor revenue reached $1.8 billion, accounting for 74% of the total MEMS-sensor industry revenue. Key growth drivers include TPMS, ESC brake sensors, side-airbag systems, stricter emissions controls (EGR pressure), and ambient-pressure monitoring.

Top Five Automotive MEMS Applications by Revenue

Electronic Stability Control (ESC)

Airbag Systems

Manifold Absolute Pressure (MAP)

Tire-Pressure Monitoring (TPMS)

Rollover Detection

Notable MEMS Applications

High-volume, high-precision, low-cost MEMS are ideal for automotive ECUs.

MEMS accelerometers are replacing legacy electromechanical accelerometers in airbag and ABS systems.

MEMS gyros in high-end vehicles support active suspension and rollover protection.

MEMS pressure sensors embedded in TPMS transmit tire pressure, temperature, and wheel speed wirelessly.

Multi-point MAP sensors improve fuel economy and emissions in EFI systems.

Silicon MEMS pressure sensors are replacing ceramic capacitive sensors in EGR systems.

China, as the world’s largest automotive producer and consumer, has become the largest market for automotive sensor applications. According to IMARC Group, the global automotive-sensor market reached $29.2 billion in 2024 and is projected to grow to $72.1 billion by 2033 (CAGR 10.04% from 2025–2033). MEMS technology is steadily displacing traditional sensors as the mainstream for automotive sensing.

China, as the world’s largest automotive producer and consumer, has become the largest market for automotive sensor applications. According to IMARC Group, the global automotive-sensor market reached $29.2 billion in 2024 and is projected to grow to $72.1 billion by 2033 (CAGR 10.04% from 2025–2033). MEMS technology is steadily displacing traditional sensors as the mainstream for automotive sensing.

Slutsats

In summary, the rapid expansion of automotive electronic control systems has driven continuous advancement in sensor technologies. Future automotive sensors will be characterized by increased intelligence, miniaturization, integration, multifunctionality, and the adoption of novel materials and processes. MEMS-based sensors are now the backbone of vehicle sensing, spanning powertrain control, body electronics, safety systems, and ADAS. As vehicles become more connected, autonomous, and electrified, the demand for high-performance, reliable, and cost-effective MEMS sensors will only grow. By 2030, global and Chinese automotive sensor markets are poised to see substantial growth, solidifying MEMS technology as the predominant choice for next-generation vehicle sensing applications.

Ovanstående introduktion repar bara ytan på tillämpningarna av trycksensorteknologi. Vi kommer att fortsätta att utforska de olika typerna av sensorelement som används i olika produkter, hur de fungerar och deras fördelar och nackdelar. Om du vill ha mer information om vad som diskuteras här kan du kolla in det relaterade innehållet längre fram i den här guiden. Om du är tidspressad kan du också klicka här för att ladda ner detaljerna i denna guide Lufttryckssensor Produkt PDF -data.

För mer information om andra sensorteknologier, vänligen Besök vår Sensors -sida.

I blog frequently and I seriously thank you for your information. This great article has truly peaked my interest. I will take a note of your blog and keep checking for new information about once per week. I subscribed to your RSS feed too.