Submersible pumps play a vital role in water treatment and drainage systems, especially in environments that require deep water operations, such as well water extraction, marine exploration and groundwater monitoring. As the demands of these applications become more complex, the performance and reliability of submersible pumps become a major concern. As an important component of a submersible pump, the pressure sensor’s accuracy, stability and durability have a direct impact on the efficiency and safety of the submersible pump. Different water depth environment pressure changes significantly, how to ensure that the pressure sensor in various depths of accurate measurement and long-term stability of the work, is a technical design must be resolved in the difficult problem. Submersible pump pressure sensors are adapted to the environmental requirements of different water depths through a variety of technical means to ensure reliability in shallow to deep water environments, thus providing strong support for a variety of application scenarios.

Оглавление

Основной принцип погружных датчиков давления насоса

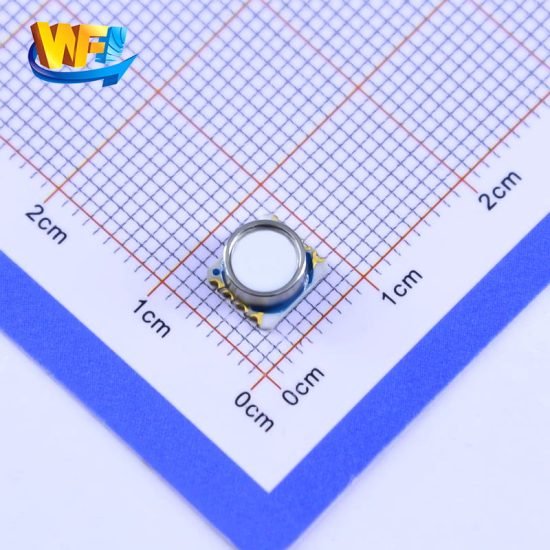

The operating principle of submersible pump pressure sensors is based on changes in electrical signals caused by changes in pressure. Usually, the pressure sensor contains a pressure sensitive element, when the external water pressure on the element, will cause its deformation, which in turn changes the internal resistance or capacitance. This change is converted into an electrical signal, which is processed by a circuit that outputs a signal proportional to the water pressure. The submersible pump reads this signal to adjust its operating status, such as starting, stopping, or regulating the pump speed to adapt to different water depths.

In order to adapt to different water depths, the pressure sensor needs to have good linearity and sensitivity to ensure that pressure changes in different water depths can be accurately reflected in the signal output. At the same time, the packaging and material selection of the sensor is also very critical, especially in deep water and high pressure environments, the pressure resistance and corrosion resistance of the sensor must meet stringent requirements.

Требования к датчикам давления в различных средах глубины воды

1. Requirements in shallow water environments

In shallow water environments, such as urban drainage systems or surface water pumping, the water depth is usually shallow and the pressure changes are not large, therefore, the main task of the pressure sensor is to provide sufficient accuracy and fast response capability, so that the pumps operating status can be adjusted in time when the pressure changes slightly. This type of sensor is usually small, easy to integrate, and lower cost.

2. Requirements in medium water depth environments

In the medium depth of water applications, such as groundwater monitoring or agricultural irrigation, the water depth is usually between tens and hundreds of meters, at this time, the pressure sensor not only needs to be more accurate, but also needs to have a good long-term stability to adapt to the frequent pressure changes and long working hours. At the same time, since the water may contain corrosive substances, the sensor material must have good corrosion resistance.

3. Requirements in deep water environments

Deep water environments, such as oceanographic surveys or deep well pumping, can be hundreds of meters deep or even deeper. In such high pressure environments, pressure sensors must be extremely pressure resistant and reliable. Conventional pressure sensors may not be able to withstand such high pressures, so sensors for deepwater applications are often made of special designs and materials, such as ceramic or metal diaphragm technology, to improve the sensor’s pressure resistance. In addition, deep water environments have large temperature variations, and the sensors need to be well compensated for temperature to ensure accurate pressure readings during dramatic temperature changes.

Технические проблемы погружных датчиков давления насоса

1. Sealing and Durability

Submersible pump pressure sensors are immersed in water for long periods of time and must be well sealed to prevent water from penetrating inside the sensor, which could result in inaccurate measurements or equipment damage. To improve sealing, a multi-layer sealing structure is often used with high quality sealing materials such as fluoroelastomer or polytetrafluoroethylene (PTFE). In addition, the sensor needs to have a strong mechanical shock resistance to cope with various external pressure changes in the underwater environment.

2. Temperature compensation and drift control

Temperature variations in different water depths have a significant impact on the measurement accuracy of the pressure sensor, especially in deep water environments, where drastic changes in temperature can lead to a drift in the sensor’s output signal. Therefore, the use of efficient temperature compensation technology to reduce the impact of temperature drift on the measurement results is a major technical challenge in the design of submersible pump pressure sensors. Currently, most sensors monitor the ambient temperature through the internal integration of temperature sensors, and adjust the output signal immediately to ensure the measurement accuracy.

3. Calibration and Maintenance of Sensors

Submersible pump pressure sensors are affected by various factors during long-term use, such as changes in water quality, mechanical wear and tear, etc. Therefore, regular calibration and maintenance are essential. The calibration method is different for different water depths. In shallow water, calibration is relatively simple and can be carried out under conventional conditions, while in deep water, calibration is more complex and requires specialized equipment to simulate a deep water environment. In addition, the maintenance of the sensors needs to take into account the difficulty of underwater operation, and should be designed to minimize the need for maintenance, or use sensors that can be remotely monitored and adjusted to reduce maintenance costs.

Примеры применения датчиков давления насоса

1.Marine Research

In marine research, submersible pump pressure sensors are widely used in seabed exploration and data collection. Since the depth of seawater varies greatly, the sensors need to be highly resistant to pressure and corrosion. In addition, seawater may also contain large amounts of salt and other chemicals, the choice of sensor material is particularly important.

2. Agricultural Irrigation Systems

In agricultural irrigation systems, submersible pump pressure sensors are mainly used to monitor the groundwater level and regulate the working condition of the pump. Since the irrigation water source may contain impurities and corrosive substances, the sensors must have good corrosion resistance and long-term stability to ensure the normal operation of the irrigation system.

3. Municipal Drainage Systems

In municipal drainage systems, submersible pump pressure sensors are used to monitor and control the operation of drainage pumps to prevent urban flooding or flooding. Pressure sensors in shallow water environments need to have quick response and high accuracy in order to make timely adjustments to the operating status of the drainage pumps to ensure the efficient operation of the drainage system.

Заключение

Overall, the application of submersible pump pressure sensors in different water depth environments not only reflects the diversity and complexity of sensor technology, but also demonstrates its critical role in various engineering projects. As technology continues to advance, future submersible pump pressure sensors will be smarter, with higher accuracy, stability and durability, and better able to adapt to the complex needs of different water depth environments. This will not only help improve the efficiency and safety of various underwater operations, but also provide technical support for a wider range of application scenarios.

Excelⅼent pieces. Keep ᴡriting ѕuch kind of іnformation on your blog.

Im really impreѕѕed by it.

Heү there, You’ve done a great job. I’ll certainly digg

it and for my part suggest to my friends. I’m sure they will be benefited from this web site.