In general, before digital processing, датчики давления часто описывают такие особенности, как гистерезис (pressure, temperature), линейность, температурный коэффициент, and other characteristic parameters in the product specifications. However, after digital processing, pressure sensors or transmitters typically no longer describe these parameter indicators when detailing output signal characteristics; instead, they provide overall measurement accuracy parameters. This difference is not because digital processing can eliminate characteristics like hysteresis, but because after digital processing it becomes difficult to distinguish whether certain characteristics such as hysteresis are caused by the sensor element’s measurement signal or by the firmware processing itself. Therefore, it is generally more reasonable to combine the measurement errors caused by гистерезис, temperature characteristics, and the quantization process into the final measurement accuracy, error, and long-term stability specifications of the product.

Каталог

Ошибки датчиков

Пока есть измерения, неизбежно будут ошибки. Для конкретных приложений, даже если ошибки существуют, они в определенном смысле относительны. Пока ошибка находится в допустимых пределах, ее можно терпеть, и профессиональные пользователи обычно следуют принципу “достаточность, затем предпочтение” when selecting sensors. In pressure sensor applications, the characteristics of concern include, but are not limited to, the following:

- Диапазон измерения давления: FSO-kPa (differential pressure/static pressure, gauge pressure/sealed gauge pressure, absolute pressure)

· Ошибка измерения давления: ±kPa

· Разрешение измерения: kPa/bit

· Рабочее напряжение/ток

· Диапазон хранения и рабочих температур, measurement medium

· Характеристики отклика давления, повторяемость, долгосрочная стабильность

Beneath these pressure parameters lie the sensor’s core or module that can convert pressure into an electrical signal. There are multiple principles for measuring pressure, but not every principle can cover all types and ranges of pressure. These principles include:

- Пьезорезист

- Разбрызгивая тонкая пленка

- Силиконовый резонанс

- Емкостный

- Вихревый ток

- Force Balance, Melted Quartz Bourdon Tube

- Датчик напряжения …

Ниже приведен краткий анализ ошибок для датчиков давления на основе пьезорезистивный principle.

Figure-1: От кремниевый чип к Различные упаковочные приложения из Пьезорезизитивные датчики давления

In Figure-1, several typical forms are listed that are widely used in various fields based on Пьезорезизитивные датчики давления from bare dies to several types of packaging. Some product types only have external packaging; some have analog signal outputs within the corresponding range that are temperature compensated and calibrated for interchangeability; some further amplify the analog signal; and others perform digital processing before outputting. There are also pressure transmitters that, after digital calibration, use corresponding interface protocols that are widely applied in industry, as well as integrated modules that include other sensors such as temperature or gas sensors for automotive, medical, and other industries. Additionally, some devices use the pressure characteristics of the medium being measured to determine other physical quantities—for example, flow sensors based on low Датчики дифференциального давления used in ventilators.

Generally speaking, before digital processing, датчики давления часто описывают такие особенности, как гистерезис (pressure, temperature), линейность, and температурный коэффициент in their specification sections. After digital processing, however, pressure sensors or transmitters typically do not describe these indicators when detailing the output signal characteristics, but instead provide overall Точность измерения parameters. This difference is not because digital processing can eliminate characteristics like гистерезис, but because it becomes difficult after digital processing to distinguish whether the characteristics (e.g., hysteresis) are caused by the sensor element’s measurement signal or by the firmware processing itself. Therefore, the measurement errors caused by гистерезис and temperature characteristics, along with quantization errors, are generally combined into the final product specifications for Точность измерения, error, and long-term stability.

Digital conditioning often seldom addresses the symmetry of the sensor bridge. If one considers the effect of the компенсировать распределение в точке нулевой нагрузки Пьезорезизивный датчик давления on the gain of the front-end amplification circuit, as well as the impact of the subsequent ADC on the effective signal (FSO) resolution due to gain variations, a comprehensive approach is required. After digital processing, unless necessary, the компенсировать is calculated from the specified zero point.

Analog compensation and calibration, before the ADC participates in processing, can significantly enhance product interchangeability by improving symmetry (0-point компенсировать output approaching 0V), Чувствительность к температуре, and output consistency. Therefore, both methods have their characteristics. In the subsequent error analysis of pressure sensors, only pressure products that have undergone temperature compensation and calibration using resistor networks will be discussed, rather than those after digital processing.

На основе характеристик Пьезорезизитивные датчики давления, the error treatment is generally divided into two types:

- Компенсируемые ошибки (generally caused by temperature effects and are repeatable)

- Некомпенсируемые ошибки (generally caused by pressure, temperature, and packaging stress, and are non-repeatable)

Of course, even for the compensable portion of the error, different compensation methods can achieve varying degrees of error cancellation.

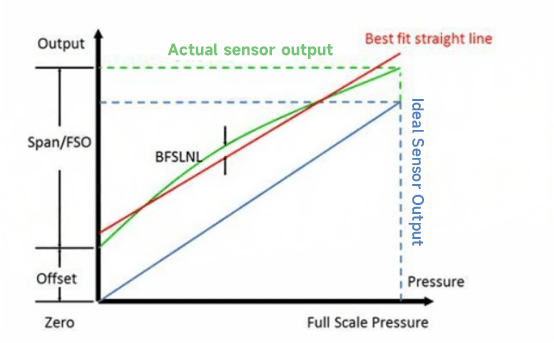

Фигура-2: Сравнение вывода характеристики (зеленый) of a piezoresistive pressure sensor at a зафиксированный температура с идеальный датчик давления выход (синий)

For the subsequent error analysis, Figure-2 shows the general output characteristics of a Пьезорезизивный датчик давления. The terms used in the figure are as follows:

- Ноль: Ideal reference zero point

- Компенсировать: Actual zero-load output deviation, i.e., the output voltage when zero load is applied

- FSO: Full Scale Output, the difference in output signal from the full scale pressure to the zero point

- Bfslnl: Non-Linearity relative to the Best Fit Straight Line

Характеристики датчика и анализ ошибок

Next, we take a detailed look at a medium-pressure 40kPa Пьезорезизивный датчик давления from WF brand. After packaging, calibration, and температурная компенсация using a 316L stainless steel pressure module, the parameters are as follows:

The data in the table (e.g. ±1% FS, etc.) is usually the final accuracy obtained “after calibration/compensation”, which has already corrected for most repeatable temperature errors, gain errors, zero bias, etc. The true “uncalibrated” deviation often takes into account various types of scatter including initial zero point, sensitivity, package stress, etc., which can easily add up to more than ±10% FS.

Истинное «некалибированные” deviation often takes into account various types of scatter, including initial zero, sensitivity, package stress, etc., which can easily add up to more than ±10% FS.

Therefore, many manufacturers only list the calibrated or compensated combined accuracy (e.g., 1% FS, 2% FS) in their “Окончательные спецификации”И не указывайте напрямую в конечном листе продукта, сколько ±% FS ошибка «Оригинал” may have.

Ошибка влияет на факторы

Типичные ошибки включают ссылку ошибки напряжения, Ошибки усилителя, Ошибки датчиков, and the effect of шум on measurement accuracy.

(1) Reference voltage error

Опорное напряжение используется для сравнения с фактическим значением измерения, so the actual value of this reference voltage is very important, and periodic calibration or software calibration of the reference voltage is required to correct this basic measurement error. A temperature coefficient of 100 ppm/°C at 0°C to 25°C will have an error of up to 2500 ppm, or 0.25% of the full scale range.

(2) Amplifier Error

Operational amplifiers can introduce errors due to their out-of-phase zero drift and other reasons. Sensor signal input operational amplifier that will affect the measurement accuracy. Such as pressure sensors, pressure sensors, for example, a 20mV full-scale signal will have a 5% offset, that is, 1mV input bias voltage. This input bias error can directly reduce the measurement accuracy, with sufficient dynamic range of the A/D converter is possible to use software to eliminate this error.

(3) Sensor Error

Sensors are unlikely to reach an ideal state because of processing, and errors can occur. It may be difficult to correct sensor errors. For example, in the case of pressure sensors, even if they are linearly calibrated during the manufacturing process, the amount of variation in the output scale factor between different devices in the application is still high. The reference voltage of the pressure sensor is usually generated by the excitation, which produces a proportional measurement method through a Whiston bridge, which eliminates the drift error to some extent, but there will still be a bias voltage generated because the bridge cannot be completely symmetrical to each other. Taking the pressure sensor as an example, the offset of 1 low pressure sensor, its bias error is largely caused by the bridge asymmetry.

(4) Noise effects

Noise has many sources, including coupled noise from nearby high-speed digital logic circuits, power supplies, fan motors, solenoid valves, and RF EMI. Noise can be reduced by proper grounding design, shielding methods and board layout. In addition, operational amplifiers can be selected that minimize introduced noise and have sufficient gain bandwidth. Operational amplifiers can be evaluated on the basis of the amount of introduced noise, which is determined from measurements of signals over an unrestricted bandwidth (wide bandwidth) or a defined bandwidth.

A/D Конвертеры

When using an A/D converter, background noise is a determining factor in the available measurement accuracy. When a device is rated for 24-bit resolution, the actual accuracy achieved by the converter is usually lower due to limitations caused by noise. A distinction needs to be made here between the effective bit and the very low noise value, where the effective bit specification is calculated from the noise level RMS value, and the very low noise value is based on the peak-to-peak value, which typically corresponds to as much as 6.6 times the statistical RMS value. Therefore, the very low noise specification indicates the effective resolution of the converter, which remains stable at LSB bits above the background noise. Special attention also needs to be paid to the limitations in the specification, such as the reference voltage and input range, which may vary from application to application, and the datasheet promises may differ considerably from the actual ratio.

Операционные усилители

Усилитель трудно достичь низкого шума и высокого усиления одновременно. It is then necessary to bring the noise level of the amplifier into the same range as its error. All semiconductor amplifiers have 1/f noise, also known as flicker noise, which is a fundamental phenomenon due to the material. Contrary to frequency, below a specific noise inflection point, the noise density increases exponentially and becomes very large at low frequencies. Few amplifiers can realize this combination of low noise and high gain characteristics in a single chip at low cost.

To achieve low noise and high gain, hybrid multi-amplifier circuits can be designed, using a combination of input amplifiers with a high input impedance, input error correction circuitry, and a second (or third) compensation amplifier to achieve the desired gain. Amplifiers that concentrate on one parameter often present serious problems in other areas.

Последние мысли

This is why, in practical applications, if we directly purchase an Неизвестный голый или Просто упакован piezoresistive pressure sensor and handle the circuit design and temperature compensation ourselves, we may face a значительное начальное смещение. However, if we buy a цифровой компенсации/калибровано pressure sensor or transmitter with built-in compensation, we can directly achieve the Меньшая общая ошибка (such as ±1% FS) indicated in the datasheet.

Вышеупомянутое введение лишь поверхностно коснулось области применения технологии датчиков давления. Мы продолжим изучать различные типы сенсорных элементов, используемых в различных продуктах, их работу, их преимущества и недостатки. Если вам нужна более подробная информация о том, что здесь обсуждается, вы можете просмотреть соответствующий контент далее в этом руководстве. Если у вас мало времени, вы также можете нажать здесь, чтобы загрузить подробную информацию об этом руководстве. Данные датчика давления воздуха PDF.

Для получения дополнительной информации о других сенсорных технологиях, пожалуйста, Посетите нашу страницу датчиков.