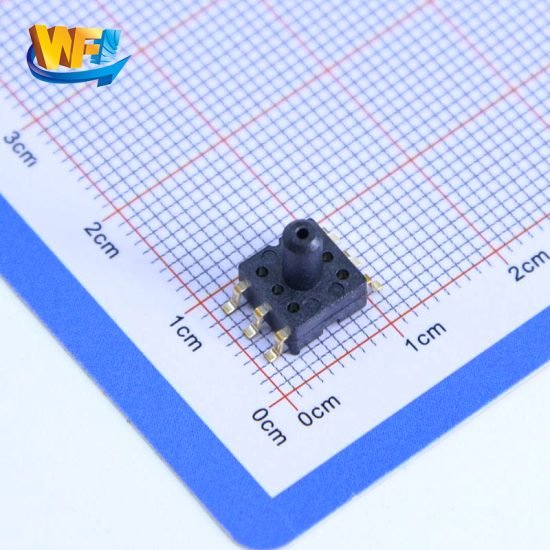

Pressure sensors play a pivotal role in breath alcohol testing. They not only ensure the quality of gas sampling during the testing process but also provide robust data support for the accurate determination of alcohol concentration. This article focuses on the WF100SPZ Датчик давления, examining its high precision, outstanding stability, rapid response, and exceptional reliability.

Каталог

Начнем разбираться!

Введение

Breath alcohol testers primarily determine whether a driver is under the influence by analyzing the alcohol concentration in exhaled breath. Their core technology depends on the precise acquisition and processing of sensor data. Traditional testing devices often encounter issues such as insufficient sample volume or unstable airflow. The introduction of a pressure sensor effectively resolves these challenges. Among them, the WF100SPZ—a high-performance pressure sensor—plays a critical role in ensuring the accuracy of breath data and the overall stability of the device.

Ключевые особенности WF100SPZ

2.1 High-Precision Measurement

The WF100SPZ offers extremely high measurement accuracy, capable of detecting minute changes in exhaled pressure. This precise pressure data provides a solid foundation for subsequent alcohol concentration calculations, significantly enhancing the accuracy of test results.

2.2 Excellent Stability

Regardless of varying environmental temperatures, humidity conditions, or extended continuous operation, the WF100SPZ maintains a stable working state. This stability ensures consistent, reliable pressure data in complex scenarios such as roadside checks and workplace testing.

2.3 Rapid Response

The sensor can quickly detect changes in exhaled pressure and convert them into electrical signals in a very short time. This rapid response not only improves testing efficiency and reduces wait times but also enhances user experience, making the detection process smoother.

2.4 Outstanding Reliability

Having undergone rigorous quality and durability testing, the WF100SPZ demonstrates high reliability and a long service life. This feature helps reduce maintenance costs and replacement frequency for applications requiring frequent and large-scale alcohol testing.

3. Working Principle & Сценарии приложения

3.1 Working Principle

In a breath alcohol tester, the pressure sensor primarily monitors the pressure changes when a user exhales. The WF100SPZ ensures that the user provides an adequate and stable breath sample, thus guaranteeing the completeness and accuracy of the data. Once the sensor captures the pressure data and converts it into electrical signals, these signals are compared and processed with data from a fuel cell or semiconductor sensor, ultimately enabling precise measurement of alcohol concentration.

3.2 Application Scenarios

- Придорожный DUI проверяет: In traffic enforcement, the WF100SPZ continuously monitors the drivers breath pressure in real time, ensuring each test meets the standard exhalation requirement.

- Инспекции безопасности на рабочем месте: In corporate or industrial settings, the pressure sensor quickly and accurately determines whether employees are at risk of working under the influence.

- Личные устройства тестирования: As personal health monitoring devices become more widespread, the WF100SPZ is increasingly used in portable breath alcohol testers, offering users a timely means of self-assessment.

Технические преимущества & Будущий перспективы

The WF100SPZ high precision, stability, rapid response, and reliability make it stand out in current breath alcohol testing, while also laying the groundwork for more intelligent and refined devices in the future. As sensor technology continues to advance, we can anticipate even higher levels of automation and intelligence in data acquisition and processing, further enhancing road safety and public health.

Заключение

As a trusted ally in breath alcohol testing, the WF100SPZ pressure sensor delivers stable and accurate data thanks to its outstanding performance and technical specifications. Whether under harsh environmental conditions or in frequent-use scenarios, it maintains highly efficient and reliable operation, significantly boosting overall testing device performance. Looking ahead, as detection technology and sensor technology evolve, the WF100SPZ and similar products will play an even greater role in driving more precise and intelligent alcohol testing, safeguarding public safety.

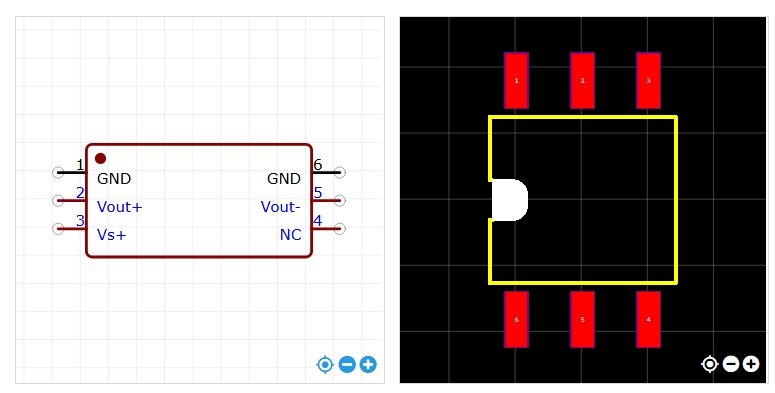

Technical Parameter Comparison: WF100SPZ vs. US9411-100

Below is a comparison of the main technical parameters between two popular models in the Alcohol test instrument sensor series (WF100SPZ ). The table shows that while they share similar supply voltage, linearity, and temperature ranges, they differ in pressure range, making them suitable for different detection needs.

| Модель | Pressure Range (Gauge) | Напряжение снабжения | Режим вывода | Эксплуатационная температура | Хранение температура | Линейность |

|---|---|---|---|---|---|---|

| WF100SPZ | 0 ~ 0.72 PSI (5 KPa) | 5В | Аналоговый выход | -20 ~ 85°C | 40 ~ 125°C | 0.3% |

| WF100SPZ | 0 ~ 1.45 PSI (10 KPa) | 5В | Аналоговый выход | -20 ~ 85°C | 40 ~ 125°C | 0.3% |

Note:

- PSI (pound-force per square inch) and KPa (kilopascal) are common pressure units used for various measurement and calibration environments.

- A smaller linearity value indicates that the sensor’s output curve is closer to an ideal linear curve over the pressure range, thus improving overall measurement accuracy.

- The operating temperature range refers to the ambient temperature in which the sensor can function normally, while the storage temperature range refers to the temperature range the sensor can withstand when not in operation.

As shown in the table, the WF100SPZ excels at detecting subtle pressure changes within a lower range, making it especially suitable for monitoring the small pressure variations required in breath alcohol testing. Meanwhile, the WF100SPZ is designed for higher accuracy pressure requirements. Selecting the appropriate model based on the actual application scenario can better ensure device performance and detection accuracy.

Вышеупомянутое введение лишь поверхностно коснулось области применения технологии датчиков давления. Мы продолжим изучать различные типы сенсорных элементов, используемых в различных продуктах, их работу, их преимущества и недостатки. Если вам нужна более подробная информация о том, что здесь обсуждается, вы можете просмотреть соответствующий контент далее в этом руководстве. Если у вас мало времени, вы также можете нажать здесь, чтобы загрузить подробную информацию об этом руководстве. Данные датчика давления воздуха PDF.

Для получения дополнительной информации о других сенсорных технологиях, пожалуйста, Посетите нашу страницу датчиков.