Safety and metering accuracy are always two of the most critical factors when we talk about gas use in homes or industry. In this regard, the application of Sensores de pressão do ar in gas meters plays a crucial role. They not only help to detect gas pressure to ensure the safe operation of the piping system, but also improve the accuracy of metering to ensure that the user’s bill is accurate.

Catálogo

Vamos começar a entender!

Gas transmission and distribution

Gas transmission, distribution and supply system is a complex and huge network, in which the safe operation of gas pipeline is the key to ensure the stability and reliability of the whole system. In the process of gas transportation, gas pipelines are affected by various factors, such as pressure fluctuations, temperature changes, etc., which may lead to cracks, leaks and other safety hazards.

In order to monitor the safety of gas pipelines in real time, pressure sensors are widely used in gas systems. These sensors are able to accurately measure pressure changes within the pipeline and transmit the data to a central control system for analysis. Once the pressure exceeds the preset safety range, the pressure sensors will immediately sound an alarm, alerting staff to take emergency measures to prevent accidents.

Sensores de pressão play an integral role in gas safety. Through real-time monitoring and early warning, they are able to detect and deal with safety hazards in the gas system in a timely manner, ensuring the safety of our lives and property. With the continuous progress of technology, the application of pressure sensors will be more extensive and in-depth, bringing more safety and convenience to our lives. If there is insufficient or excessive gas pressure in the equipment, the pressure sensor will send out a signal in time to remind the user or maintenance personnel to deal with it and avoid safety accidents caused by gas supply problems.

The core function of the air pressure sensor

Flow Detection

Air pressure sensors are able to accurately measure gas flow by monitoring pressure changes as the gas flows. This is important for accurate metering, as the flow rate directly affects the cost of gas usage. Combined with the pressure data, the air pressure sensor is able to compensate for deviations in the flow measurement and provide more accurate billing data.

Wireless Meter Reading

Many gas meters have now realized the wireless meter reading function. Through the combination of air pressure sensors and intelligent systems, operators can remotely read the pressure and flow data of gas meters. This not only improves work efficiency, but also avoids the trouble of manual meter reading and reduces the error rate.

Gas Pressure Detection

Gas pressure is the basis for safe operation. The air pressure sensor can monitor the pressure situation in the gas meter in real time. If the pressure exceeds or falls below the set threshold, the sensor can automatically alarm to remind the user or operator to take timely measures to avoid danger.

Alarm when gas leakage pipeline pressure is low

Air pressure sensors are also able to detect abnormal pressure in gas pipes. If a leak occurs in the pipeline, the air pressure will drop significantly, the sensor will immediately send an alarm signal to remind the user or relevant personnel to take emergency measures to effectively prevent accidents.

Pressure-compensated flow measurement

Some high-end gas meters are able to pressure compensate the flow measurement by air pressure sensor. Under different environmental conditions, the volume of gas may change, and through accurate pressure compensation, the gas meter can always provide accurate flow measurement, ensuring that every gas bill is calculated more fairly and accurately.

Technical characteristics of gas meter pressure sensors

1. I2C digital interface

Modern gas meters use the I2C digital interface to communicate with microcontrollers (MCU). This interface not only supports high-speed data transfer, but also ensures efficient collaboration between the sensor and the gas meter system, providing real-time feedback of pressure data for easy monitoring by users and operators.

2. Internal calibration and temperature compensation

To ensure accurate measurements, the air pressure sensor has built-in temperature compensation. This means that the sensor automatically adjusts its measurements to changes in ambient temperature, preventing temperature fluctuations from interfering with the data. In addition, the sensor is factory calibrated to ensure accuracy and reliability.

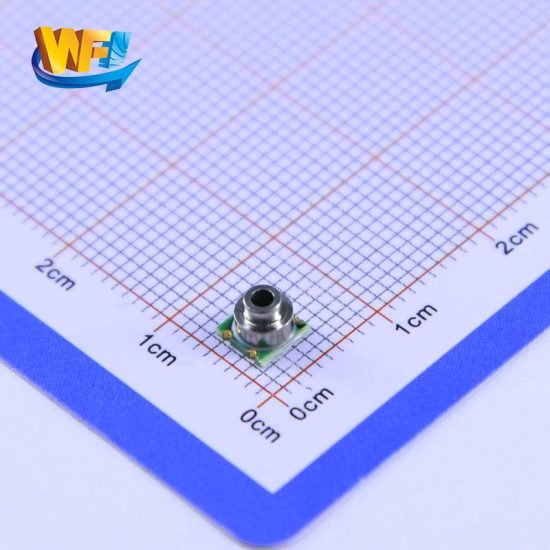

3. Waterproof design

Given that gas meters are often installed outdoors or in wet environments, waterproofing is critical. Modern air pressure sensors feature a waterproof design that enables them to work stably in inclement weather, unaffected by external moisture.

4. Highly Accurate Pressure Measurement

Air pressure sensors typically have a pressure accuracy of ±0.3kPa (±3.0mbar) @ 25°C, which means it can accurately measure the pressure inside the gas meter, ensuring accurate operation of billing and safety systems.

5. Low voltage operation

Gas meter pressure sensors typically operate from a supply voltage range of 1.8V to 3.6V (3V typical). This low voltage design allows the sensor to consume very little power for long term operation and eliminates the need for frequent battery replacements, making it ideal for use in smart gas meters.

6. RoHS Compliant

As an environmental requirement, the material of the gas meter pressure sensor is RoHS compliant and halogen-free, which means it contains no harmful heavy metals or halogens, and is environmentally friendly, safe and reliable.

Gas meter pressure sensor selection:

Choosing the right air pressure sensor is very critical, I believe you have already made a wise choice by reading this, the following elements can help you pick the most suitable product or reference:

Measuring range and pressure (how many Bar for accurate measurement)

For gas meters, the pressure range that usually needs to be measured is 0 to 5 Bar (i.e., 0 to 500 kPa), and sometimes higher ranges are needed, especially in industrial applications. To ensure accuracy, it is important to select a sensor with an adequate pressure range. For example, common pressure sensors typically offer measurement ranges of 0-1 Bar, 0-5 Bar, or 0-10 Bar. Choosing the right pressure range ensures that the sensor can cope with all possible pressure fluctuations.

Interfaces and Data Transfer

Selecting an air pressure sensor that supports the I2C interface greatly improves compatibility with the MCU, which is essential for integration into a smart gas meter system.The I2C interface provides faster data transfer speeds and ensures that pressure data is fed back in real time.

Environmental Protection and Certification

Ensuring that the selected sensor is RoHS compliant and halogen-free not only complies with environmental regulations, but also ensures its long-term stability in various applications.

Water and Weather Resistance

Since gas meters are often used outdoors, the devices need to be waterproof and heat resistant. Ensuring that the air pressure sensor has a good waterproof rating (e.g. IP65 or higher) is essential.

How to reduce costs and maintain value for money?

When choosing an air pressure sensor, cost effectiveness is an important point of consideration in every purchasing decision. Here are a few tips to help you keep costs down while ensuring the quality and consistency of your sensors:

1. Choose long-term reliable suppliers: Look for suppliers who have long-term industry experience and can provide quality products. Long-term cooperation can lead to more competitive prices, and high-quality suppliers usually provide better after-sales service and technical support.

2. Purchase in volume: By purchasing in bulk, you can get a lower unit price. Many sensor suppliers offer bulk order discounts, which is especially beneficial for gas meter manufacturers who purchase air pressure sensors in bulk.

3. Balancing Accuracy and Cost: For general applications, choosing a slightly less accurate sensor doesn’t mean sacrificing too much performance. If your application doesn’t require much accuracy, you can choose a lower-cost sensor, but still make sure it meets minimum accuracy standards.

4. Select the right material and design: The material and design of the sensor can have a significant impact on cost. Select the right material for your needs and simplifying the design can reduce costs without compromising the overall performance and stability of the product.

Why are air pressure sensors so important in gas meters?

The air pressure sensor is the core component of a modern smart gas meter. It is not only directly related to the accuracy of billing, but also to the safety of gas usage. By monitoring gas pressure in real time, the air pressure sensor effectively prevents leaks, broken pipes and other potential safety risks, providing a safer environment for users. It also ensures accurate calculation of gas costs by compensating for pressure variations in flow measurements, allowing users to enjoy fair billing.

Selection of invasive pressure sensors

Range: -50mmHg to 300mmHg

- The sensors can be adapted to a wide range of blood pressure monitoring needs, covering ranges as low as -50mmHg to 300mmHg, and are suitable for a variety of clinical scenarios.

Gauge Pressure Types

- The sensor supports gauge pressure types to ensure that the measurement data meets clinical needs, especially for monitoring ambulatory blood pressure changes.

MEMS Technology

- Adopting advanced MEMS technology, the sensor is able to provide high-precision, low-power and long-life performance to meet the high requirements of medical devices.

Calibration and Compensation

Conclusão: Medição precisa, suporte confiável

The use of air pressure sensors in gas meters brings increased safety and metering accuracy. They ensure pipeline safety by accurately monitoring gas pressure, avoiding leaks and optimizing flow metering. In addition, choosing the right supplier and sensor type ensures performance and value for money while reducing costs. As technology continues to advance, air pressure sensors will play an increasingly important role in gas management. Hopefully, this article will help you better understand the importance of air pressure sensors in gas meter pressure detection!

A introdução acima apenas arranha a superfície das aplicações da tecnologia de sensores de pressão. Continuaremos a explorar os diferentes tipos de elementos sensores usados em vários produtos, como funcionam e suas vantagens e desvantagens. Se desejar mais detalhes sobre o que é discutido aqui, você pode verificar o conteúdo relacionado posteriormente neste guia. Se você está sem tempo, também pode clicar aqui para baixar os detalhes deste guia Dados PDF do produto do sensor de pressão de pressão de ar.

Para obter mais informações sobre outras tecnologias de sensores, por favor Visite nossa página de sensores.