Teach everyone to understand the digital display air pump sensor, that is, the application of air pressure sensor in the air pump

OVERVIEW

In recent years, along with the rapid development of science and technology, our daily life continues to be intelligent, digital and convenient. One of the “core souls” supporting these intelligent lifestyles is sensors. Sensors can help us transform information that is difficult to visualize and judge into more visual, accessible and accurate data, thus building the cornerstone of our new lifestyle.

There are many types of sensors, and the range of applications extends from the industrial field to all walks of life.

CATÁLOGO

- 1.The working principle of inflatable pump:

- 2. Air pump display mode is divided into traditional pointer type and digital display

- 3. Digital display inflatable pump overall part

- 4. What is the difference between the two kinds of air pressure sensors

- 5.Summary

1.The working principle of inflatable pump:

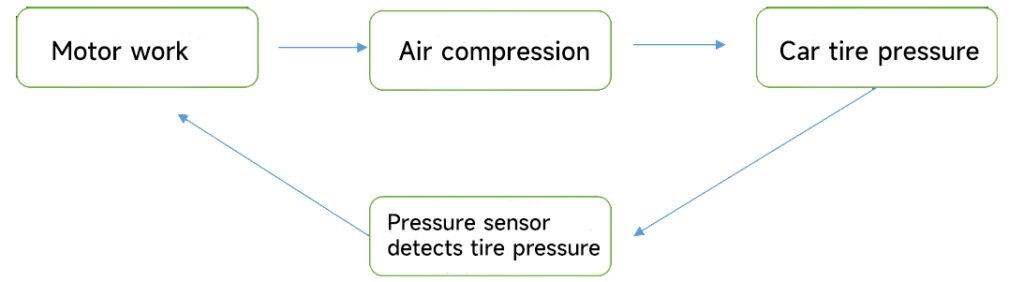

Inflatable pump, also called inflator, pump, works through the operation of the motor, is a kind of inflatable tool. Its working principle: the motor runs, when pumping, the valve of the connecting device is flushed open by the air pressure of the atmosphere, and the gas enters the air cylinder, and when pumping to the tire, the valve is closed by the air pressure inside the air cylinder, and the gas enters the tire, the use of the principle of gas compression, the compression of the air or other gases into a high-pressure gas, which can be used for the inflating of tires of transportation vehicles (e.g., bicycles, cars), basketballs, footballs and so on. The principle of electronic air pump is to use mechanical or electric force to compress the gas to reduce its volume and increase the pressure, so as to achieve the purpose of inflation.

Electronic air pump is mainly composed of Sensor de pressão, microprocessor, low noise motor, charger and other parts. When the air cushion or gas container needs to be inflated, the pressure sensor of the intelligent inflatable pump will automatically sense the current gas pressure and feed back to the microprocessor. Under the control of the microprocessor, the low-noise motor starts working to compress the gas and send it into the air mattress or container. During the inflation process, the pressure sensor of the electronic air pump will constantly monitor the change of gas pressure, and when the pressure reaches the set value, the electronic air pump will automatically stop working to prevent the tire pressure from being too high and leading to a flat tire.

According to its working principle, it can be seen that the switching of pressure in the inflation pump is crucial, so the pressure sensor plays a key role in it. A high sensitivity pressure sensor can make the inflation pump work more smoothly and precisely.

2. Air pump display mode is divided into traditional pointer type and digital display

1. The following pictures are of an inflatable pump using a traditional pointer gauge.

The air pump of the traditional pointer barometer will use the analog air pressure sensor 1100kPa/11bar

2. Digital display will be more intuitive, and set the working mode, air pressure reaches the set value, you can automatically stop, to prevent over-inflation leading to flat tires; display intuitive, easy to use.

Digital inflatable pumps use air pressure sensors. Nowadays, the general range of the inflatable pump is 150PSI ≈ 1034Kpa, which can meet most of the use scenarios, you can choose WF183DE 1100Kpa or 1500Kpa two ranges of Sensor de pressão do ar.

Air pressure unit: 1bar = 100,000 Pa = 0.98692327 atm

1psi = 6.895kPa = 0.0689476bar = 0.006895MPa

3. Digital display inflatable pump overall part

It includes control chip, digital display screen and air pressure sensor (pressure sensor), air pump assembly.

The cost of the pump assembly is the most expensive organization, accounting for about 1/3 ratio, and the pump assembly is particularly critical to the inflatable pump air volume indicators.

The most important part of the function of the digital inflatable pump is the air pressure sensor. The project is good or bad, high or low precision indicators, will be affected by the air pressure sensor, so to speak, to do a good job of inflatable pumps, if the sensor does not understand that will suffer a big loss, believe it or not, you try to know! How many digital inflatable project of the abortive cause is from the air pressure sensor. Now take you focus on the air pressure sensor in the air pump in the general situation. Digital inflatable pumps now have two solutions, analog air pressure sensor (WF162L) and digital air pressure sensor (WF183DE). More than 80% of the market now are analog air pressure sensors, which can also be called piezoresistive sensors.

4. What is the difference between the two kinds of air pressure sensors

The following is focused on analyzing the difference between the two types of barometric pressure sensors, the cost of what is probably the case.

1. Analog barometric pressure sensor, WF162L LGA8 package, for example, the cost is about 0.15USD or so, if the accuracy needs to be done within 2%, 24-bit AD that is the first choice, the master also needs to be with differential signals of the dual-channel AD, but also need to be with the op-amp, if you want to eliminate the power management IC, that is, you have to more than 1 road AD, this type of master in the market is less, and the price are relatively high; Analog air pressure air pressure there is a more complex calibration process, I looked at many factories calibration environment, are very unstandardized, unprofessional. Calibration of the pressure controller used is only an air compressor plus air pressure gauge, no precision to speak of;

2. Digital barometric pressure sensor to WF183DE LGA8 package, for example, the cost is more than twice as high as the analog sensor, about 0.3usd or so, because the digital output for the IIC communication, you can directly use the IO to simulate the IIC directly using the choice of the master does not need to be with the AD, pure IO can be, choose the model is easy, inexpensive, and the most important thing is the digital barometric pressure sensor with temperature Output, this function is indispensable in the field of inflatable pumps, many inflatable pumps is because of the inflatable process of high temperature leads to air pressure value drift, the controller has no way to accurately let the pump shut down. This program also has the advantage that the user is free of calibration, no calibration, means the factory has been calibrated, inflatable pump manufacturers do not need to use the production line calibration!

3. The only consistent advantage is: both models are protected by waterproof gel, which can effectively prevent moisture, ensure high linearity, high sensitivity, low temperature drift and high reliability, with miniaturization, high precision, high sensitivity, high reliability and so on. The core part is a silicon piezoresistive pressure sensitive chip processed by MEMS technology, when there is pressure acting on the chip, it will produce a voltage output signal that is linearly proportional to the added pressure, which can be widely used in the measurement of products related to air pressure.

Summary:

In summary, CNC inflatable pumps if precision is required, digital air pressure sensor should be the best solution, in fact, the two ways to calculate by BOM and production costs, digital air pressure sensor will not be higher than analog sensors, because many analog sensors are now used in the application of the addition of the NTC to achieve temperature compensation, in line with the RoHS standard, so the generation of difficulty is constantly increasing, and the chances of a bad Therefore, it is becoming more and more difficult to produce and the chance of failure will also increase.

Source: Sensores WF