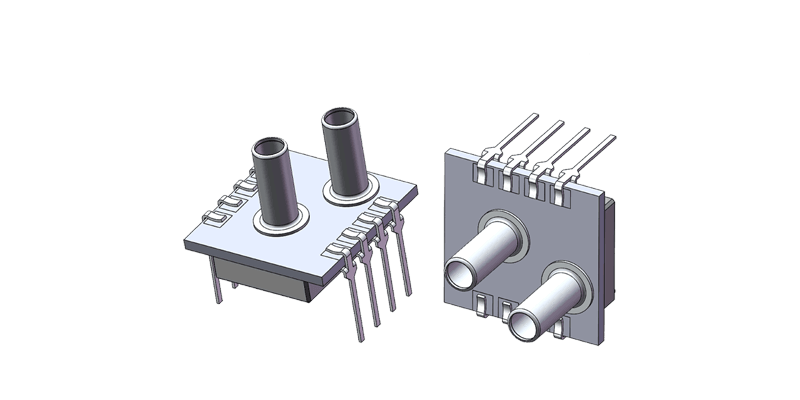

Sensores piezoresistivos para TPMS direto: medição precisa da pressão dos pneus

A direct tyre pressure monitoring system measures the pressure inside each tyre with sensors mounted on the wheel and transmits that data wirelessly to an in-cabin receiver. Compared with indirect systems, it can show the instantaneous absolute pressure for every tyre. Sensitivity and resolution determine whether the system will alert early enough.

Sensores piezoresistivos para TPMS direto: medição precisa da pressão dos pneus Leia a postagem »