Sport Equipment Pressure Sensors | Response Time 1ms

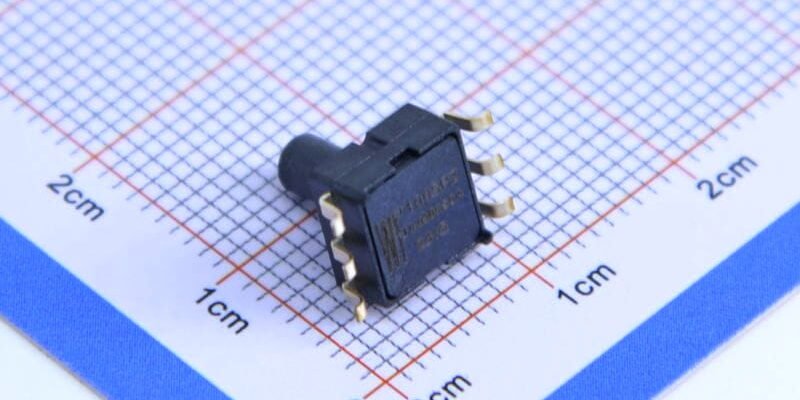

Integrating high accuracy pressure sensors into sports equipment not only enables real-time capture of instantaneous pressure changes but also dynamically adjusts device status based on the environment. With an ultra fast 1ms response time, it provides precise and stable intelligent control support for sports gear.