Katalog

Let’s start understanding!

Why do draft beer dispensers need pressure sensors?

The modern draft beer dispenser is more than just a simple liquid dispensing device; it is a system that requires a high degree of precision control. Whether its a commercial bar or restaurant, or a homebrewing facility, ensuring that the flow rate of the beer, the ratio of foam, and the level of carbonation are consistent is a core factor in the user experience. Pressure sensors play a vital role in this process.

How do sensors optimize draft beer dispenser performance?

The core function of a pressure sensor is to monitor the pressure of a gas or liquid in real time to ensure optimal hydrodynamic parameters. In draft beer dispenser applications, it is used in the following areas:

- Carbonation control: to ensure that CO2 pressure is kept in the appropriate range to maintain optimal bubble quality.

- Flow rate regulation: avoiding too fast or too slow flow of beer and ensuring smooth pouring.

- Foam Management: Control foam formation to minimize waste and improve the taste of the beer.

- Backflow and leakage prevention: Avoid beer backflow or leakage by detecting abnormal pressure changes, reducing maintenance costs.

Select the Right Pressure Sensor: Analog vs Digital

There are two main types of pressure sensors on the market today: analog sensors (amplified) dan digital sensors. In draft beer dispenser applications, analog sensors are often preferred due to their fast response time, low cost, and simple construction.

Advantages of analog sensors:

- Low power consumption for long running equipment.

- High accuracy, up to 0.4%FS level, to meet the precise regulation needs of draft beer dispensers.

- Suitable for 3.3~5.5V power supply environment, compatible with a variety of circuit designs.

- Standard voltage output or proportional voltage output, easy to integrate.

- Fast response time, suitable for real-time monitoring and control.

- Simple structure, high reliability, easy to maintain and replace.

In contrast, digital sensors are suitable for more sophisticated intelligent control systems, but are more costly and may have slightly less response time than analog sensors. As a result, analog sensors remain the dominant choice in most commercial or home draft beer dispensers.

Analysis of key parameters: How to select the right sensor?

Select the right pressure sensor requires focusing on the following core parameters according to the specific application needs of the draft beer dispenser:

Measuring range:

-100kPa to 100kPa, covering the pressure needs of different draft beer dispensers.

Accuracy (0.4%FS):

Affects the reliability of pressure measurement and directly determines the accuracy of flow rate and foam control.

Gauge pressure type design:

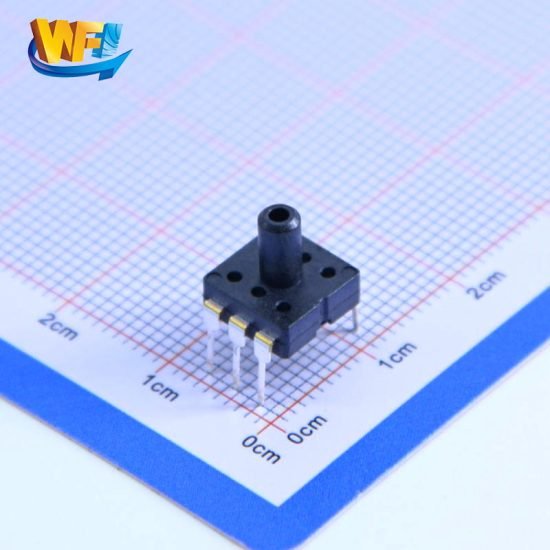

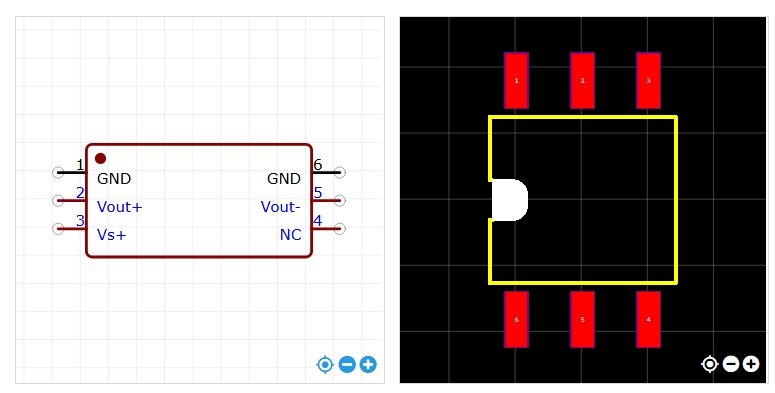

DIP6 package, suitable for non-corrosive gases, ensuring long-term stable operation.

Temperature drift:

the effect of temperature change on measurement accuracy, especially suitable for bars or outdoor scenes with large fluctuations in ambient temperature.

Output offset and sensitivity:

Determines the signal quality of the sensor and affects the responsiveness of the control system.

Balancing Cost and Performance

For draft beer dispenser manufacturers, cost control is a key factor in product design. Analog sensors offer a cost advantage over digital sensors, while still providing sufficient accuracy and stability. Choosing the right sensor not only improves product competitiveness, but also reduces maintenance costs and enhances the user experience.

Kesimpulan

Pressure sensors are an integral core component of modern draft beer dispensers. By choosing the right analog sensor, manufacturers can reduce costs and increase the competitiveness of their products in the marketplace while ensuring precise control. Whether it’s a commercial or home draft beer dispenser, accurate pressure control results in a smoother pouring experience, more consistent foam management, and longer equipment life. Optimizing the selection of pressure sensors is a critical step in improving product quality for draft beer dispenser manufacturers who want to increase user satisfaction.

Pengenalan di atas hanya menggaru permukaan aplikasi teknologi sensor tekanan. Kami akan terus meneroka pelbagai jenis elemen sensor yang digunakan dalam pelbagai produk, bagaimana mereka bekerja, dan kelebihan dan kekurangan mereka. Jika anda ingin lebih terperinci mengenai apa yang dibincangkan di sini, anda boleh menyemak kandungan yang berkaitan kemudian dalam panduan ini. Sekiranya anda ditekan untuk masa, anda juga boleh klik di sini untuk memuat turun butiran panduan ini Data PDF Produk Sensor Tekanan Udara.

Untuk maklumat lanjut mengenai teknologi sensor lain, sila Lawati Halaman Sensor kami.