Katalog

A dual-measurement MEMS pressure sensor with two pressure ports and integrated ASIC captures pitot (total) and static pressure, providing digital outputs and temperature compensation. The device achieves total error within 0.5%FS across −25°C to 85°C, with a differential range of 10–100 mbar and an absolute range of 200–1200 mbar. Single-supply operation (1.8–5.5 V) supports dry air and non-corrosive gases. This article focuses on how the sensor improves accuracy and reliability for airspeed, barometric altitude, and vertical speed measurements in aviation applications.

1. Design and Core Technologies

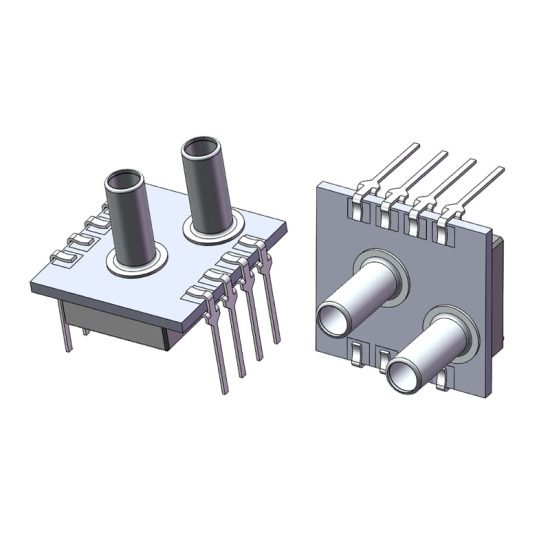

Sensor architecture and dual-port layout

The sensor uses two pressure ports—one for total pressure and one for static pressure—so the ASIC can perform front-end amplification, filtering, and A/D conversion and output calibrated digital pressure values. The dual-port layout directly captures pitot/static signals, removing diaphragm lag and wear issues and improving consistency and repeatability of airspeed and altitude data. This design simplifies direct interfacing with flight-control buses or standalone processors.

2. Signal Conditioning and Temperature Compensation

Signal conditioning and temperature compensation implementation

An on-chip ASIC implements programmable temperature compensation across −25°C to 85°C, keeping total error under 0.5%FS. The ASIC handles amplification, linearization, and drift correction, and digital outputs reduce analog interference. The single-supply 1.8–5.5 V design eases power management and fits embedded flight controllers and data loggers.

3. Application Value in Aviation Measurements

How differential and absolute channels work together for airspeed and altitude

By reading total and static pressure simultaneously and computing dynamic pressure (total − static), the sensor yields more accurate airspeed references (indicated and true airspeed). The absolute channel directly provides atmospheric pressure for altitude estimation and barometric altimeters. High sampling rates and low drift make vertical speed (rate of climb/descent) calculations smoother and more responsive, supporting timely flight-control decisions.

4. System Integration and Reliability

Mechanical and electrical integration considerations

The device supports through-hole PCB mounting and standard mechanical interfaces. Differential range is 10–100 mbar; absolute range is 200–1200 mbar. It is compatible with dry air and non-corrosive gases. Vibration, thermal cycling, and pressure cycling tests validate device stability. Digital interfaces enable direct connection to flight-control ASICs or microcontrollers, reducing the need for extra signal-conditioning hardware and improving system integration and maintainability.

5. Calibration, Testing, and Deployment Recommendations

Calibration and verification approach for flight and test environments

Perform initial system-level calibration and environmental assessment, and tune the temperature-compensation curve and filtering to match operational flight conditions. For wind-tunnel tests or in-flight use, verify the dynamic pressure calculations and altitude derivations across the full signal chain so sensor outputs align with flight-control algorithms and system expectations.

Summary points: Dual differential and absolute measurement provides the complete pitot/static solution; integrated ASIC and temperature compensation achieve ±0.5%FS over a wide temperature range; digital output and single-supply operation simplify flight-control integration; ranges and interfaces meet wind-tunnel and airborne test requirements; high sample rate and low drift improve airspeed, altitude, and vertical-speed reliability.

Kesimpulan

Using a dual-measurement MEMS sensor for aviation pressure sensing preserves the core pitot measurement principle while removing mechanical weaknesses. Temperature compensation, ASIC signal conditioning, digital output, and compatible supply voltage enable higher accuracy and consistent outputs for airspeed, barometric altitude, and vertical-speed measurements, making the sensor straightforward to deploy in flight-control systems and test benches.

Pengenalan di atas hanya menggaru permukaan aplikasi teknologi sensor tekanan. Kami akan terus meneroka pelbagai jenis elemen sensor yang digunakan dalam pelbagai produk, bagaimana mereka bekerja, dan kelebihan dan kekurangan mereka. Jika anda ingin lebih terperinci mengenai apa yang dibincangkan di sini, anda boleh menyemak kandungan yang berkaitan kemudian dalam panduan ini. Sekiranya anda ditekan untuk masa, anda juga boleh klik di sini untuk memuat turun butiran panduan ini Data PDF Produk Sensor Tekanan Udara.

Untuk maklumat lanjut mengenai teknologi sensor lain, sila Lawati Halaman Sensor kami.