Каталог

Agricultural weather stations rely on accurate pressure data, but barometric sensors often face harsh outdoor conditions (rain, dust, frost, agrochemicals). Waterproof digital on-board pressure sensors can improve system reliability in such environments. Written from the customer’s perspective, this article covers key considerations when replacing older sensors: environmental requirements, digital interface benefits, installation practices, and pre-production testing. The information is based on public sources (e.g. Wikipedia) and industry experience, to help engineers and decision-makers make informed choices.

1. Special Requirements for Pressure Sensors in Agricultural Meteorological Monitoring

Agricultural weather stations operate in harsh outdoor environments. Sensors are exposed to sunlight, rain, humidity, dust, agrochemicals, and wide temperature swings. Robust packaging and corrosion-resistant materials (e.g. stainless steel housing and IP67-rated seals) are mandatory to prevent water or debris ingress that could cause drift or failure

The sensor must provide accurate atmospheric pressure readings in the relevant range. Typical sea-level pressure is about 300–1100 hPa. The U.S. National Weather Service specifies standard barometers covering about 16.9–31.5 inches of mercury (≈570–1070 hPa) with resolutions down to 0.003 inches (≈0.1 hPa). Sensors for agricultural use should therefore offer high precision and stability over that range, including built-in compensation for temperature and humidity variations.

2. Technical Advantages of Digital On-Board Pressure Sensors

Digital on-board pressure sensors convert the pressure signal directly into a digital output. They include built-in 24-bit sigma-delta ADCs and temperature compensation, providing high precision measurements without external components. These sensors communicate via standard I²C or SPI interfaces, which simplifies integration and reduces signal noise. By eliminating the need for external A/D conversion, they make system design cleaner and more robust.

Key advantages include:

High precision and integration: On-chip 24-bit ADCs and internal compensation yield very high resolution and accuracy, simplifying calibration.

Digital interface simplifies integration: Standard I²C/SPI buses make it easy to connect the sensor to microcontrollers or data acquisition systems, streamlining system design.

Low power and maintenance: Digital sensors often support sleep modes and have lower overall power consumption. They can also be updated with software adjustments instead of replacing hardware

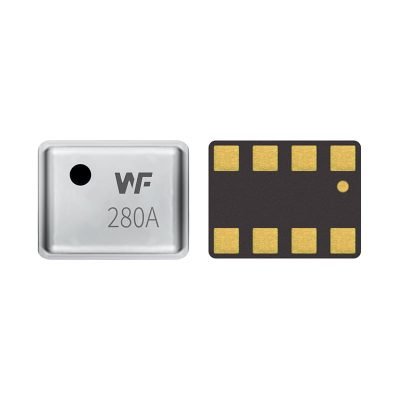

In addition to the advantages of the WF5805C sensor, the WF280A sensor also offers its own distinctive technical strengths. The WF280A comes in an ultra-compact 8-pin LGA metal package (approximately 2.0×2.5×1.0 mm), making it ideal for space-constrained meteorological monitoring devices. It integrates a MEMS silicon piezoresistive sensing element with a high-resolution 24-bit ΔΣ ADC, enabling high-precision digital pressure output (typical relative accuracy around ±0.12 hPa) to meet the stringent requirements of pressure and altitude measurements.

The sensor supports a standard I²C digital interface, simplifying communication with the host MCU and streamlining data acquisition. An ultra-low-power design is another highlight of the WF280A: at a 1 Hz sampling rate, the typical operating current is only about 5.4 μA, making it well suited for solar- or battery-powered outdoor monitoring systems. In addition, the WF280A can operate reliably over a wide temperature range from –40 °C to +85 °C and features a sealed package design that effectively prevents moisture and dust ingress. These characteristics enable the WF280A to maintain reliable performance in harsh outdoor environments, providing a high-precision, low-power pressure measurement solution for agricultural meteorological monitoring.

3. Installation and Soldering Considerations for Pressure Sensors

Proper assembly is critical for sensor performance. Key points include:

Solder paste and stencil: Use no-clean solder paste to avoid the need for cleaning. Apply the correct amount of paste (thickness 3.5–6 mil is recommended) to prevent solder from flowing into the sensor port.

Placement technique: If the sensor has a top-side pressure port, use standard pick-and-place equipment and avoid touching the port with a vacuum nozzle. Do not solder the sensor by hand to prevent overheating or mechanical stress.

Port protection: After soldering, inspect the port for any blockage from flux or debris. If a conformal coating is applied, mask the pressure port to keep it clear, so that the sensor only responds to environmental pressure.

4. Testing and Measurement Process Before Mass Production

Before full production, sensors should undergo rigorous testing to ensure quality. Important steps include:

Pressure calibration: Use a precision pressure source (deadweight tester or regulator) to apply known pressures at multiple points (e.g. 0%, 50%, 100% of full scale). Measure the output and adjust calibration coefficients for offset and scale.

Temperature cycling: Test the sensors in an environmental chamber across the operating range (e.g. −20°C to +60°C) to evaluate temperature effects on output and verify internal compensation.

Batch consistency: Perform statistical testing on batches of sensors, comparing zero offset, sensitivity, nonlinearity, etc., to ensure devices meet specs uniformly. Discard any units that fall outside tolerance.

Long-term stability (drift): Conduct aging tests (such as holding sensors at near-full-scale pressure for an extended period) and compare readings before/after to quantify drift.

- Interface and EMI/ESD testing: Verify digital communication (I²C/SPI) works correctly and check EMI/ESD immunity, ensuring the sensor functions reliably in the target system.

5. Ensuring Long-Term Stability in Agricultural Applications

To maintain accuracy over years of use, focus on both design and maintenance:

High-quality materials and sealing: Use corrosion-resistant materials (such as stainless steel or plated housing) and reliable seals to block humidity, dust, and chemicals. Sturdy design (IP67-rated) guards against environmental degradation wfsensors.com.

Production burn-in and aging: Perform accelerated aging tests during production (for example, hold sensors at high pressure for an extended time) to measure and compensate for long-term drift.

Temperature compensation: Rely on internal temperature compensation and linearization algorithms to minimize the impact of ambient temperature changes. Additional software-level compensation can further correct any residual drift.

Periodic recalibration: Implement a maintenance schedule to recalibrate sensors and check zero offset/sensitivity over time, ensuring any gradual shifts are corrected.

Redundancy and monitoring: For critical applications, consider redundant sensors or trend analysis. Monitor pressure readings for unexpected changes so that sensors can be serviced or replaced before failures occur.

Заклучок

Agricultural weather monitoring places high demands on pressure sensor reliability and accuracy. When replacing older sensors, engineers should focus on practical requirements: environmental protection, interface compatibility, and performance specifications. Using modern digital MEMS sensors with waterproof, corrosion-resistant packaging can simplify system integration and improve stability. Coupled with robust installation practices and thorough testing, this approach ensures long-term dependable operation. The right selection and maintenance strategy will keep agricultural monitoring equipment providing accurate pressure data to support decision-making.

Горенаведениот вовед само ја гребе површината на апликациите на технологијата на сензорот за притисок. Ќе продолжиме да ги истражуваме различните типови на сензорски елементи што се користат во различни производи, како тие функционираат и нивните предности и недостатоци. Ако сакате повеќе детали за она што се дискутира овде, можете да ја проверите поврзаната содржина подоцна во ова упатство. Ако сте притиснати за време, можете исто така да кликнете овде за да ги преземете деталите за овој водич Податоци за производ на сензорот за притисок на воздухот PDF.

За повеќе информации за други технологии на сензори, ве молиме Посетете ја страницата на нашите сензори.