Cycling Computer with Air Pressure Sensor for Real-Time Wind Speed

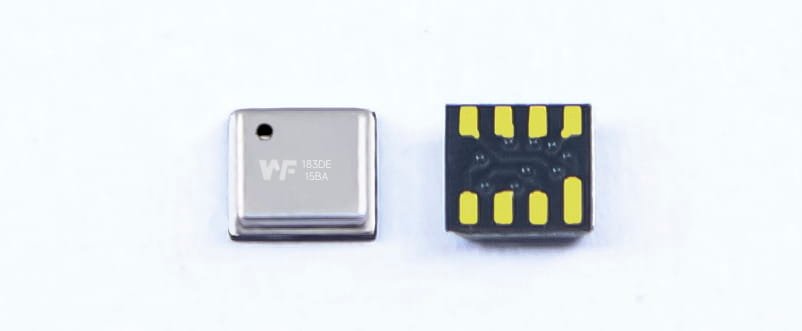

MEMS air pressure sensor enables precise wind speed measurement in bicycle computers using resistive technology, featuring low power consumption, waterproof design, and temperature compensation for reliable real-time environmental data.

-e1747998312687.jpg)