Water level indicators are widely used in daily life and industrial scenes, and their accuracy and stability directly affect the normal operation of the equipment. The application of pressure sensors in liquid level measurement provides a more efficient and reliable solution to the traditional measurement method. However, the use of pressure sensors as core components often leads to the following problems:

- Is the accuracy of the pressure sensor sufficient for level measurement?

- How to install the pressure sensor to ensure the stability of the measurement?

- Do I need to calibrate the pressure sensor periodically for long-term use?

Let’s start understanding!

ລາຍການ

What is Pressure Sensor?

Pressure sensor ແມ່ນອຸປະກອນທີ່ປ່ຽນສັນຍານຄວາມກົດດັນເປັນສັນຍານໄຟຟ້າທີ່ສາມາດວັດແທກໄດ້. ໃນຄໍາຮ້ອງສະຫມັກຕົວຊີ້ວັດລະດັບນ້ໍາ, ເຊັນເຊີຄິດໄລ່ລະດັບຄວາມສູງທີ່ສອດຄ້ອງກັນໂດຍການກວດສອບການປ່ຽນແປງຂອງຄວາມກົດດັນຂອງແຫຼວ. ວິທີການນີ້ແມ່ນມັກສໍາລັບໂຄງສ້າງທີ່ງ່າຍດາຍແລະການຕິດຕັ້ງງ່າຍຂອງມັນ.

ຫຼັກການເຮັດວຽກຂອງເຊັນເຊີຄວາມກົດດັນ:

ເຊັນເຊີຄວາມກົດດັນຄວາມຮູ້ສຶກການປ່ຽນແປງຂອງຄວາມກົດດັນພາຍນອກໂດຍຜ່ານອົງປະກອບທີ່ລະອຽດອ່ອນພາຍໃນ, ເຊັ່ນ: ຊິບ piezoresistive ຫຼືໂຄງສ້າງ capacitive, ແລະປ່ຽນເປັນສັນຍານແຮງດັນເສັ້ນ. ຄວາມກົດດັນຂອງຂອງແຫຼວແມ່ນເປັນເສັ້ນທີ່ກ່ຽວຂ້ອງກັບຄວາມເລິກຂອງມັນ, ດັ່ງນັ້ນໂດຍການກວດສອບຄວາມກົດດັນສາມາດສະທ້ອນເຖິງລະດັບຂອງແຫຼວໄດ້ຢ່າງຖືກຕ້ອງ.

ເປັນຫຍັງຕ້ອງເລືອກເຊັນເຊີຄວາມດັນ:

- ຄວາມຖືກຕ້ອງສູງ: ຄວາມຜິດພາດການວັດແທກຂອງເຊັນເຊີຄວາມກົດດັນປົກກະຕິແລ້ວສາມາດຄວບຄຸມພາຍໃນ± 0.5%, ເຫມາະສົມສໍາລັບສະຖານະການວັດແທກລະດັບນ້ໍາຫຼາຍທີ່ສຸດ.

- ຄວາມທົນທານ: ເຊັນເຊີຄວາມກົດດັນລະດັບອຸດສາຫະກໍາຈໍານວນຫຼາຍແມ່ນຢູ່ໃນສະແຕນເລດ, ເຊິ່ງທົນທານຕໍ່ການກັດກ່ອນສູງແລະເຫມາະສົມສໍາລັບການນໍາໃຊ້ໃນໄລຍະຍາວ.

- ຄ່າໃຊ້ຈ່າຍຕ່ໍາ: ເມື່ອປຽບທຽບກັບວິທີການວັດແທກລະດັບອື່ນໆ (ເຊັ່ນ: ເຄື່ອງວັດແທກລະດັບ ultrasonic ຫຼື radar), ຄ່າໃຊ້ຈ່າຍໂດຍລວມຂອງເຊັນເຊີຄວາມກົດດັນແມ່ນເອື້ອອໍານວຍຫຼາຍ.

ສະຖານະການຄໍາຮ້ອງສະຫມັກເຊັນເຊີຄວາມກົດດັນໃນຕົວຊີ້ວັດລະດັບນ້ໍາ

ການກວດຫາລະດັບຖັງນໍ້າໃນຄົວເຮືອນ

In household water tanks, pressure sensors are used to measure water pressure changes at the bottom of the tank to get a real-time view of the water level. Such applications require less accuracy, but need to ensure that the sensor is waterproof.

Industrial Tank Level Monitoring

In industrial production, the level of chemical or fuel storage tanks needs to be accurately monitored. The use of pressure sensors allows real-time transmission of liquid level data and remote monitoring through industrial control systems, greatly improving work efficiency.

Agricultural irrigation systems

ໃນຊົນລະປະທານກະສິກໍາ, ການເກັບຮັກສານ້ໍາມັກຈະຖືກນໍາໃຊ້ໂດຍສົມທົບກັບຕົວຊີ້ວັດລະດັບສໍາລັບການນໍາໃຊ້ນ້ໍາທີ່ມີປະສິດທິພາບ. ເຊັນເຊີຄວາມກົດດັນແມ່ນການແກ້ໄຂທີ່ຕ້ອງການສໍາລັບລະບົບຊົນລະປະທານເນື່ອງຈາກການບໍລິໂພກພະລັງງານຕ່ໍາແລະຄຸນສົມບັດທີ່ມີປະສິດທິພາບດ້ານຄ່າໃຊ້ຈ່າຍ.

ຈຸດສໍາຄັນສໍາລັບການຕິດຕັ້ງເຊັນເຊີຄວາມກົດດັນ

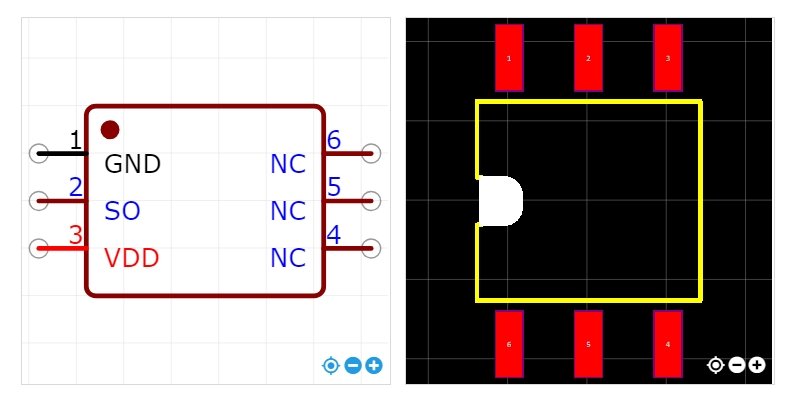

ເຊັນເຊີຄວາມດັນໃນຕົວຊີ້ວັດລະດັບນ້ໍາບໍ່ໄດ້ຕິດຕັ້ງຢູ່ໃນລັກສະນະ flanged, threaded ຫຼື suspended, ແຕ່ແມ່ນ mounted ໂດຍກົງໃນ PCB ໂດຍການ soldering. ການອອກແບບນີ້ມີຂໍ້ດີດັ່ງຕໍ່ໄປນີ້:

- ປັບປຸງຄວາມຫນ້າເຊື່ອຖື: ວິທີການຕິດຕັ້ງ solder ຫຼຸດຜ່ອນການແຊກແຊງຂອງການສັ່ນສະເທືອນພາຍນອກກ່ຽວກັບຄວາມຖືກຕ້ອງຂອງການວັດແທກ.

- ຄ່າໃຊ້ຈ່າຍທີ່ຫຼຸດລົງ: ບໍ່ຈໍາເປັນຕ້ອງມີສ່ວນແກ້ໄຂເພີ່ມເຕີມ, ຫຼຸດຜ່ອນຄ່າໃຊ້ຈ່າຍໃນການຕິດຕັ້ງ.

- ຄວາມງ່າຍຂອງການບໍາລຸງຮັກສາ: ການຕິດຕັ້ງ PCB ເຮັດໃຫ້ມັນງ່າຍຕໍ່ການປ່ຽນຫຼືສ້ອມແປງເຊັນເຊີໃນຂັ້ນຕອນຕໍ່ມາ.

ກ່ຽວກັບ Calibration

ໃນສະຖານະການຄໍາຮ້ອງສະຫມັກຫຼາຍທີ່ສຸດ, ໄດ້ ເຊັນເຊີຄວາມກົດດັນ ໄດ້ຮັບການປັບທຽບເບື້ອງຕົ້ນຢູ່ໃນໂຮງງານຜະລິດແລະບໍ່ມີການປັບເພີ່ມເຕີມແມ່ນຕ້ອງການໂດຍຜູ້ໃຊ້. ຢ່າງໃດກໍ່ຕາມ, ຖ້າໃຊ້ໃນສະຖານະການທີ່ມີຄວາມແມ່ນຍໍາສູງ, ແນະນໍາໃຫ້ມີການກວດສອບຈຸດສູນແລະໄລຍະເປັນໄລຍະເພື່ອຮັບປະກັນຄວາມຫມັ້ນຄົງຂອງການວັດແທກໃນໄລຍະຍາວ.

FAQ

①ວິທີການເລືອກລະດັບຂອງເຊັນເຊີຄວາມກົດດັນ?

ຊ່ວງຂອງເຊັນເຊີຄວນໄດ້ຮັບການເລືອກຕາມຄວາມສູງສູງສຸດຂອງລະດັບນ້ໍາ. ຕົວຢ່າງ, ສໍາລັບຖັງທີ່ມີຄວາມເລິກສູງສຸດ 4 ແມັດ, ແນະນໍາໃຫ້ເລືອກເຊັນເຊີຄວາມກົດດັນທີ່ມີລະດັບ 0 ~ 40kPa.

② ສິ່ງສົກກະປົກໃນນ້ໍາຈະມີຜົນກະທົບຕໍ່ການວັດແທກບໍ?

ໂດຍທົ່ວໄປແລ້ວ, ຄວາມບໍ່ສະອາດໃນນ້ໍາບໍ່ມີຜົນກະທົບໂດຍກົງຕໍ່ຄວາມຖືກຕ້ອງຂອງການວັດແທກຂອງເຊັນເຊີຄວາມກົດດັນ. ຢ່າງໃດກໍ່ຕາມ, ແນະນໍາໃຫ້ເຮັດຄວາມສະອາດພອດກວດຫາຂອງເຊັນເຊີເປັນປົກກະຕິເພື່ອຫຼີກເວັ້ນການອຸດຕັນທີ່ມີຜົນກະທົບຕໍ່ຄວາມຫມັ້ນຄົງຂອງຂໍ້ມູນ.

③ ເຊັນເຊີຄວາມດັນສາມາດປ່ຽນແທນດ້ວຍວິທີອື່ນໄດ້ບໍ?

Ultrasonic level gauges or capacitive level sensors can be used as alternatives, but their cost and complexity are usually higher than that of pressure sensors, and they have higher requirements for the installation environment.

ສະຫຼຸບ

The application of pressure sensors in water level indicators has become the preferred solution for level measurement by virtue of its efficiency, accuracy and low cost. In actual use, the service life and measurement stability of the sensor can be significantly improved through proper installation and maintenance.