목록

1. Needs and scenario analysis

The core demands for agricultural water-level measurement are continuity, reliability and compatibility: wells, reservoirs, channels and underground pipes all present different liquid conditions, and measurement points often face sediment, corrosive fluids and electromagnetic interference. In engineering terms, sensor readings must be converted into actionable control signals to drive pumps, valves and scheduling logic, so that water is supplied on demand, waste is reduced and crop water needs are kept stable. Selection must also weigh installation convenience, maintenance cost and compatibility with existing controllers, ensuring sensors give immediate data while maintaining accuracy over the long term.

2. Core sensor features and selection

Sensor selection key points

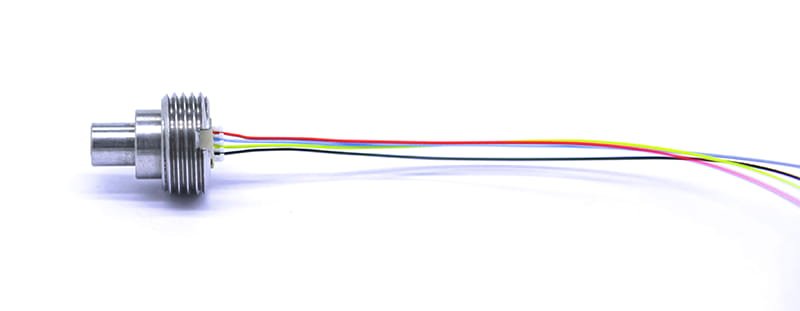

Sensor choice should centre on measurement range, output types and environmental rating. For agricultural level measurement, favour modular devices that cover 1 to 400 PSI and offer both analogue and digital outputs; prefer standard configurations available to buy online and models certified for hazardous areas so they can handle various liquids and gases. Look for sensors that can measure gauge, sealed and absolute pressure and, when needed, temperature or capacitance. Optional lightning protection and small-diameter variants help fit sensors into pipes and wells.

These features make it possible to match sensors to shallow and high-pressure scenarios, simplify interfacing with PLCs or remote nodes, and safely deploy in confined or risky locations.

3. Integration architecture and signal processing

Integration and signal consistency

At the integration level, the emphasis is on consistent outputs and sampling reliability. Using sensors that support both analogue and digital outputs simplifies signal conditioning; store calibration curves, include short-circuit and surge protection, and ensure sampling rates and filtering match the controller’s timing. When connecting to low-power telemetry or fieldbus, pay attention to protection ratings, grounding and electromagnetic compatibility to preserve steady long-term readings and fast response.

From an engineering perspective, plan the signal chain for impedance matching and interference rejection, use differential measurement or shielded cabling to cut environmental noise, and ensure the control loop receives regular, reliable data for threshold or PID actions.

4. Application implementation and control strategies

Control strategy and redundancy design

Control strategies should target precise water levels, combining threshold control with closed-loop PID or adaptive gain tuning to deliver staged irrigation and suppress oscillation. Sensors must provide sufficient resolution for tight error control; at critical points use multi-point measurements for redundancy and apply consistency checks and data fusion to reduce false alarms. Where site constraints demand it, opt for surge-protected or small-diameter sensors to fit tight installations, reducing downtime risk and improving water-use efficiency.

Key implementation elements include matching sampling rates to control cycles, setting sensible debounce and hysteresis parameters, and ensuring outputs are both analogue-friendly and ready for digital remote transmission so central monitoring and edge decisions can run in parallel.

5. Calibration, verification and reliability management

Before putting sensors into service, perform calibration and on-site comparisons to establish baseline response curves and error tolerances; during operation use periodic data comparisons and anomaly detection to spot drift or damage. At design stage, select appropriate protection ratings and corrosion-resistant materials. For hazardous or corrosive locations, prioritise certified models compatible with many liquids and gases. Optional lightning protection and small-diameter choices add installation flexibility and lower maintenance complexity and downtime costs.

결론

To make water-level pressure sensors the core sensing element in agricultural automation, select devices with range coverage (1–400 PSI), analogue and digital outputs, hazardous-area approvals, liquid/gas compatibility and optional surge protection or small-diameter variants. At system level, ensure signal consistency, match sampling rates and use multi-point redundancy; doing so materially improves irrigation and water-supply responsiveness and reliability, enabling tighter water control and better resource use.

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.