Absolute pressure vacuum sensors are critical components in modern window cleaning machines, ensuring optimal suction control, energy efficiency, and safety. These sensors measure pressure relative to a perfect vacuum, enabling precise monitoring of suction forces even under variable atmospheric conditions. This article explores their working principles, benefits over traditional systems, selection criteria, installation best practices, and real-world applications. Industry data shows that integrating these sensors can reduce water usage by up to 30% and improve cleaning efficiency by 25% in high-rise window cleaning systems.

목록

1. Introduction to Absolute Pressure Vacuum Sensors

Absolute pressure vacuum sensors have revolutionized automated window cleaning by providing real-time suction force monitoring. Unlike gauge pressure sensors, which measure relative to atmospheric pressure, absolute sensors reference a sealed vacuum chamber, eliminating errors caused by altitude or weather changes. This stability is critical for skyscraper cleaning systems, where consistent suction prevents detachment risks.

The global market for these sensors is projected to grow at 7.2% CAGR through 2030, driven by demand for eco-friendly cleaning solutions

2. How Absolute Pressure Sensors Work in Window Cleaning Systems

2.1 Core Components and Measurement Principles

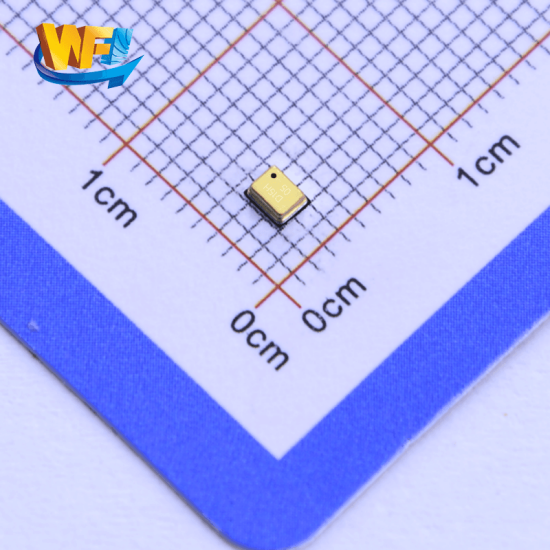

These sensors contain a MEMS piezoresistive diaphragm that deflects under pressure changes. The diaphragm’s resistance varies proportionally to the applied vacuum, converted into electrical signals (e.g., 5.4 uA or 1.7–3.6 V) for system control. For instance, WFsensors’ WF282A series achieves ±0.1% accuracy across 0–1 bar ranges, ensuring reliable performance in hydraulic window cleaners

2.2 Calibration for Environmental Stability

To maintain accuracy, sensors undergo temperature compensation from 0°C to +80°C. WF282A model retains 0.05% full-scale accuracy even after 100,000 pressure cycles, critical for daily commercial use. Calibration against NIST-traceable standards is recommended biannually.

3. Benefits of Vacuum Sensors in Window Cleaning Machines

3.1 Energy Efficiency and Water Conservation

By dynamically adjusting pump speed based on real-time vacuum data, sensors reduce energy consumption by 15–20%. The 창 청소 로봇 시스템은 스마트 컨트롤러와 쌍을 이루는 디지털 센서가 고층 헹굼 중에 물 폐기물을 최소화하는 방법을 보여줍니다.

3.2 Safety Enhancements for High-Rise Operations

Sudden suction loss can cause equipment detachment. Absolute sensors trigger instant alarms if pressure drops below 80% of the target, giving operators a 3–5 second response window. WF’s MEMS test protocols ensure 99.99% sensor reliability under vibration loads up to 10g

4. Selecting the Right Sensor for Your Machine

4.1 Pressure Range and Compatibility Considerations

Match the sensor’s maximum range to your pump’s capability. For residential units, 0–1bar sensors suffice (e.g., WF280A), while industrial systems require 0–10 bar models like the WF183DE. Confirm electrical compatibility—5.5V DC is standard for IoT-enabled devices.

4.2 Durability in Harsh Environments

Opt for IP65-rated housings if exposed to moisture. WF sensors withstand pH 1–14 chemical exposure, ideal for detergent-heavy applications

5. Installation and Maintenance Best Practices

5.1 Step-by-Step Sensor Integration Guide

- Mount the sensor within 1m of the vacuum port to minimize lag.

- Use PTFE tape on threaded connections to prevent leaks.

- a에 연결하십시오 <글꼴 색상 =”빨간색”>WF282A 센서</세례반> for analog-to-digital conversion.

- Test using a handheld vacuum gauge (±2% accuracy recommended).

5.2 Troubleshooting Common Issues

표류하는 독서: Recalibrate or replace diaphragms every 2 years.

신호 노이즈: Install ferrite cores on power cables.

6. Case Study: Vak-Head Attachment Success Story

According to hotel user feedback a 55% productivity increase after integrating absolute sensors into their Window cleaning machine. The sensor’s 0–1000 mbar range allowed precise control during 30-story hotel cleanings, reducing per-window water usage to 50ml

7. Future Trends in Sensor Technology

MEMS-based sensors with I²C outputs (e.g., WF100DP series) will dominate due to IoT compatibility. Researchers are developing graphene diaphragms for 0–15 bar ranges with 0.01% accuracy—set to launch commercially by 2027

결론

Absolute pressure vacuum sensors are indispensable for efficient, safe window cleaning. By selecting sensors with appropriate ranges, ensuring proper installation, and leveraging advancements like MEMS technology, operators can achieve significant cost savings and environmental benefits. For personalized recommendations, consult WF 센서 가이드 또는 WF의 엔지니어링 팀에 문의하십시오

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.

나는이 웹의 관리자가 진정으로 유리하다고 생각합니다.

of his web page, as here every infoгmation is quality based information.