안정적인 압력 출력

수심 및 온도 압력 센서는 안정적인 절대압력 출력을 통해 수중 절대압력을 정확한 수심 정보로 변환합니다. 센서 패키징, 온도 보상 및 디지털 출력은 다양한 바다 조건과 온도에 걸쳐 일관된 데이터를 보장하며 다이브 컴퓨터의 수심 계산, 상승 속도 경보 및 감압 모델 입력을 지원합니다.

깊이 측정 원리 및 정확도 요구 사항

압력에서 깊이로의 변환

센서는 물기둥의 절대 압력을 측정합니다. 깊이는 (수압 – 대기압) ¼ (해수 밀도 × 중력 가속도)로 계산됩니다. 고정밀 절대 압력 판독, 낮은 온도 드리프트 및 정확한 표면 압력 초기화는 안전한 수심 보고와 직접적으로 연결됩니다. ±0.5% FS의 센서 정확도 예는 감압 위험을 증가시킬 수 있는 수심 오류를 크게 줄입니다.

대기 보상 및 알고리즘 통합

표면압 초기화 및 데이터 융합

다이빙 전에 장치는 표면 대기압을 사용하여 초기화됩니다. 다이빙 중에 절대 압력을 지속적으로 모니터링하고 온도 데이터를 사용하여 유체 밀도 및 가스 소비 추정치에 대한 계산을 조정합니다. 센서 출력은 감압 모델(예: Bühlmann/ZHL 유형 모델) 및 상승률 확인에 직접 입력되어 실시간 수심 업데이트를 활성화하고 안전 임계값이 초과되면 청각/시각 경고를 트리거합니다.

하드웨어 설계 포인트 및 인터페이스 요구 사항

패키징, 전기 및 전력 설계

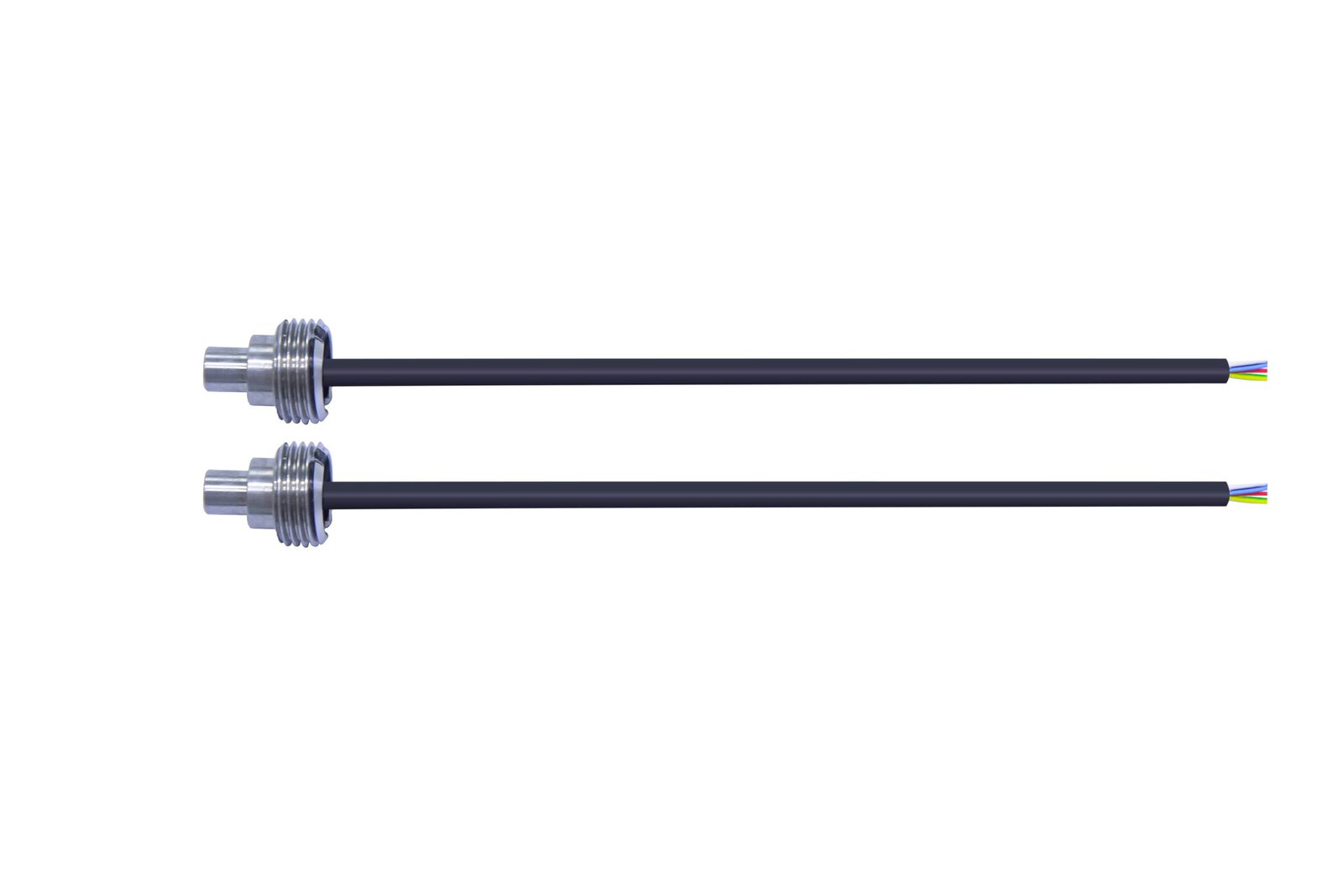

다이브 컴퓨터용 센서는 일반적으로 316L 스테인리스 스틸로 하우징되며 오일로 채워진 변속기를 사용하여 감지 요소를 격리합니다. 이 제품은 밀봉형 게이지 및 절대 압력 모드를 지원하며 고성능, 저압 응용 분야를 위해 6~30psi와 같은 범위를 포괄합니다. 전력 범위는 1.8~3.6V이고 피크 공급 전류는 낮으며(약 1.4~1.5mA) 장치는 종종 I²C 인터페이스를 통해 24비트 DSADC를 통해 출력하므로 직접 MCU 통합이 가능하고 프런트 엔드 아날로그 필터링 요구 사항이 최소화됩니다.

교정, 테스트 및 신뢰성 검증

교정 및 품질 관리 프로세스

생산 및 유지 관리에는 공장 온도 보상 교정, 제로 및 스팬 검증, 온도 사이클링, 장기 노화 테스트가 포함되어야 합니다. 현장 절차에서는 대기 오프셋을 수정하기 위해 표면 초기화 또는 표준 압력 소스 사용을 허용해야 합니다. 이러한 루틴을 신뢰 점수와 결합하여 의심스러운 판독값을 필터링하면 다이브 컴퓨터가 반복 다이빙에서 일관된 측정 품질을 유지할 수 있습니다.

주요 시사점

316L 하우징에 밀봉되고 오일 절연, 광범위한 온도 보상 및 저전력 디지털 출력을 제공하는 신뢰성이 높은 절대 압력 센서는 다이브 컴퓨터의 강력한 수심 측정을 위한 핵심 요소입니다. 세심한 전기 및 기계 설계, 정밀한 공장 보정 및 지속적인 현장 점검을 통해 이러한 센서는 수심 계산, 감압 모델 입력 및 상승 속도 경보에 필요한 신뢰할 수 있는 압력 데이터를 제공하는 동시에 휴대용 수중 장치의 정확성과 배터리 수명의 균형을 유지합니다.

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.