- 에 의해 WF센서

Smart wristband sensors play a central role in personal health management. Wristband pressure sensors together with optical heart-rate readings form a multi-dimensional physiological sensing system.

Smart wristbands are now a go-to for ongoing health tracking, with several sensing elements inside picking up different signals. To get stable, verifiable heart-rate readings you need to match a sensor’s physical traits to the whole signal chain. Here we discuss sensible sensing schemes and engineering calibration so that data collected during everyday wear is useful for diagnosis — helping users keep tabs on cardiac load, activity intensity and sleep recovery. We’ll move through the system-engineering logic: from components and algorithms to product rollout.

목록

1. Technology principles and components of wristband sensors

The heart-rate data in a wristband mainly comes from optical skin-surface measurement, combined with motion sensors. A well-designed sensor module needs careful consideration of the light path, the light source driver, the photodetector and the mechanical mount that holds everything against the skin — all to keep signal quality steady across different lighting and skin conditions. To cut down motion artefacts, systems often take short reference samples at the acquisition edge and then do time-series alignment and noise checks in software. From an engineering standpoint, sensor choice, packaging and mechanical interfaces directly affect signal robustness and long-term drift. Studying users’ wearing habits gives quantitative inputs for strap shape and contact-area design, which helps make measurements more reliable in daily use.

To quantify the performance differences between different designs.

Measurement accuracy is heavily affected by where and how the band is worn and by skin condition. Product design should therefore iterate on strap materials, contact geometry and sensor layout so that common activities — brisk walking, running or doing household chores — still yield continuous physiological waveforms. Hardware must be tightly coupled with the signal chain to avoid mechanical looseness or optical blockage causing data dropouts.

2. Wristband pressure sensors and cooperation with other sensors

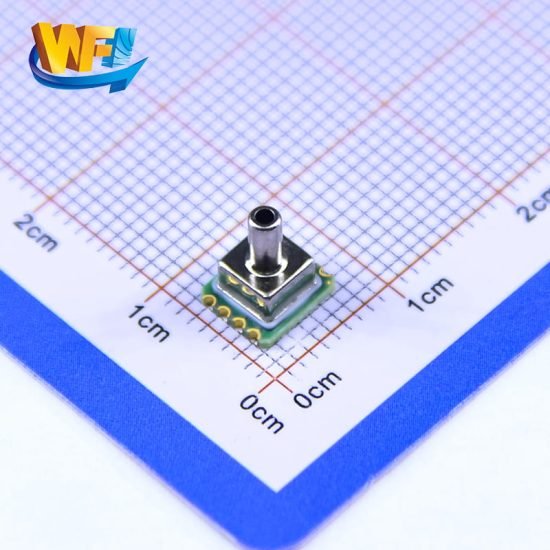

Besides optical sensing, tiny embedded pressure sensors add extra environmental or physiological context. Compact MEMS absolute-pressure devices can measure local air pressure changes for altitude estimation or provide auxiliary cues related to small respiratory-driven chest movements; some packages support coupling to the skin or a small chamber to capture local pressure fluctuations. Correlating these pressure readings with heart-rate signals can improve the interpretation of anomalies and help discriminate activity states. As a manufacturer, you need to balance packaging, sensitivity, response time and long-term stability, and keep strict process control over package base and pad layout to ensure reliability in wearable conditions.

Suitable for use as a smart bracelet sensor

The uploaded image shows a small sensor with a metal lead structure marked “WF”; it has a compact package, an exposed pressure port and multiple solder pads — suited for space-limited wearables. Such devices typically offer low drift, good linearity and compact packaging, making them a fit for smart-watch sensors, fitness band sensors and smart-clothing sensors. In engineering practice, evaluate the electrical interfaces, package moisture resistance and mechanical fixation method to ensure repeatable measurements after prolonged wear.

3. Engineering strategies to improve heart-rate monitoring accuracy

Turning a device from “it can measure” into “it measures accurately” requires work on both hardware and software. On the hardware side, pick low-noise sensors and stable light-source drivers, and optimise the contact geometry and surface treatment to reduce light scattering and slippage. On the software side, build an end-to-end data-quality assessment pipeline so each step — sampling, filtering, anomaly detection and final metric export — is traceable. Offering adaptive parameters for different user groups (sedentary vs high-activity users) cuts down false positives noticeably. System engineering should also plan validation testing: run multi-scenario trials to gather baseline performance data, which helps with later product claims and compliance.

Power consumption and accuracy

Finding the right trade-off between power use and accuracy is crucial. Wearables run on tight energy budgets, so hardware operating modes and data-upload policies must align with power-management strategies. Using sensible sampling windows and edge-triggered capture lets you keep essential information while saving battery life, giving users longer stretches between charges. Engineering teams should set target power metrics early and refine the sensor drivers and firmware logic through iterative testing.

4. Data processing, calibration and real-time feedback

High-quality heart-rate outputs depend on solid calibration routines and transparent error reporting. Devices should get initial calibration at manufacture and then use local self-calibration to offset temperature shifts and long-term drift. For real-time feedback, timely, clear prompts help wearers adjust placement or rest, which in turn improves later data. From an engineering-observability angle, provide device-side logs, end-to-end timestamp alignment and cloud-side quality dashboards so technical decision-makers can quickly pinpoint issues and iterate.

Laboratory testing and real-world environmental testing

Algorithm and device validation ought to include both lab and real-world tests. Labs let you control variables and set benchmarks, while real-world tests reveal the effects of wearing posture, sweat and clothing occlusion. Before launch, create quality gates including statistical distributions of key performance metrics and an anomaly-handling plan, supporting any public claims on measurement accuracy and stability.

5. Deployment advice and productisation considerations

Moving from engineering to mass production means tackling component supply stability, packaging consistency, environmental robustness and software maintenance. If heart-rate monitoring is a primary selling point, involve your supply chain early on with package specs and reliability-testing plans. Manufacturers must manage batch-to-batch variability in wearable MEMS sensors and set up robust incoming inspection procedures. Productisation also needs attention to user experience and regulatory compliance so the device can be approved across different regulatory regions without hiccups.

Product quality improvement process

Quality assurance for productisation covers not just part specs but also process controls for soldering, sealing and rapid testing. Good test fixtures and automation cut yield issues during ramp-up. Engineering teams should prepare a comprehensive test matrix covering temperature, humidity, mechanical shock and long-term drift, ensuring mass-produced units meet the designed performance before shipping.

결론

On the question of how to achieve more accurate heart-rate monitoring in smart wristband sensors, this article offers a systematic set of engineering recommendations: component selection, packaging and mechanical design, power and sampling strategies, data processing and calibration, through to mass-production concerns. The right mix of sensor combination and validation workflows lets devices deliver dependable heart-rate data in everyday wear, boosting health-management efficiency.

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.