목록

이해를 시작합시다!

Why do draft beer dispensers need pressure sensors?

The modern draft beer dispenser is more than just a simple liquid dispensing device; it is a system that requires a high degree of precision control. Whether its a commercial bar or restaurant, or a homebrewing facility, ensuring that the flow rate of the beer, the ratio of foam, and the level of carbonation are consistent is a core factor in the user experience. 압력 센서 play a vital role in this process.

How do sensors optimize draft beer dispenser performance?

The core function of a pressure sensor is to monitor the pressure of a gas or liquid in real time to ensure optimal hydrodynamic parameters. In draft beer dispenser applications, it is used in the following areas:

- Carbonation control: to ensure that CO2 pressure is kept in the appropriate range to maintain optimal bubble quality.

- Flow rate regulation: avoiding too fast or too slow flow of beer and ensuring smooth pouring.

- Foam Management: Control foam formation to minimize waste and improve the taste of the beer.

- Backflow and leakage prevention: Avoid beer backflow or leakage by detecting abnormal pressure changes, reducing maintenance costs.

Select the Right Pressure Sensor: Analog vs Digital

There are two main types of pressure sensors on the market today: analog sensors (amplified) 그리고 디지털 센서. In draft beer dispenser applications, analog sensors are often preferred due to their fast response time, low cost, and simple construction.

Advantages of analog sensors:

- Low power consumption for long running equipment.

- High accuracy, up to 0.4%FS level, to meet the precise regulation needs of draft beer dispensers.

- Suitable for 3.3~5.5V power supply environment, compatible with a variety of circuit designs.

- Standard voltage output or proportional voltage output, easy to integrate.

- Fast response time, suitable for real-time monitoring and control.

- Simple structure, high reliability, easy to maintain and replace.

In contrast, digital sensors are suitable for more sophisticated intelligent control systems, but are more costly and may have slightly less response time than analog sensors. As a result, analog sensors remain the dominant choice in most commercial or home draft beer dispensers.

Analysis of key parameters: How to select the right sensor?

Select the right pressure sensor requires focusing on the following core parameters according to the specific application needs of the draft beer dispenser:

Measuring range:

-100kPa to 100kPa, covering the pressure needs of different draft beer dispensers.

Accuracy (0.4%FS):

Affects the reliability of pressure measurement and directly determines the accuracy of flow rate and foam control.

Gauge pressure type design:

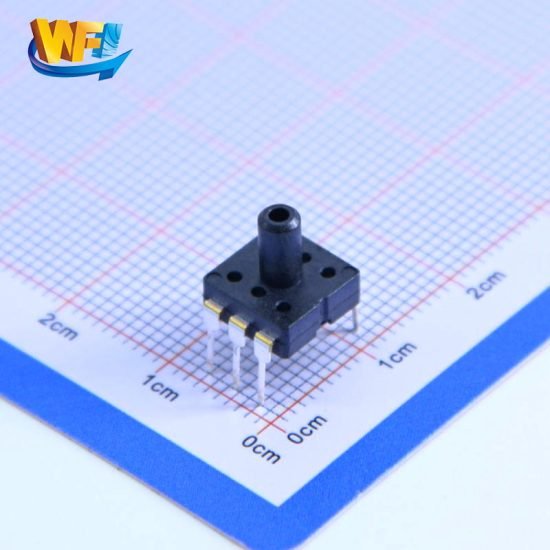

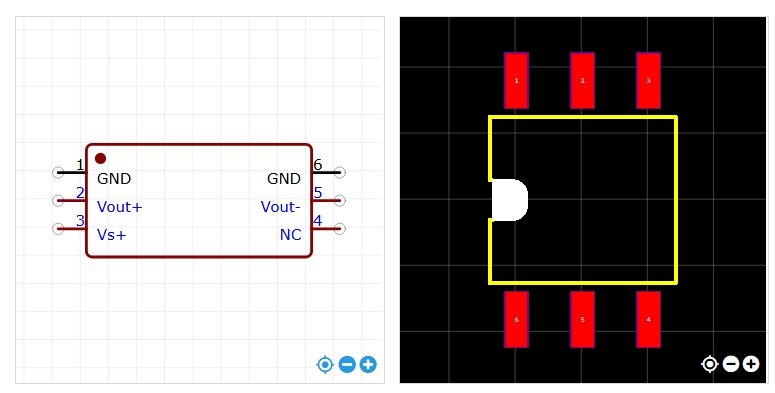

DIP6 package, suitable for non-corrosive gases, ensuring long-term stable operation.

Temperature drift:

the effect of temperature change on measurement accuracy, especially suitable for bars or outdoor scenes with large fluctuations in ambient temperature.

Output offset and sensitivity:

Determines the signal quality of the sensor and affects the responsiveness of the control system.

Balancing Cost and Performance

For draft beer dispenser manufacturers, cost control is a key factor in product design. Analog sensors offer a cost advantage over digital sensors, while still providing sufficient accuracy and stability. Choosing the right sensor not only improves product competitiveness, but also reduces maintenance costs and enhances the user experience.

결론

Pressure sensors are an integral core component of modern draft beer dispensers. By choosing the right analog sensor, manufacturers can reduce costs and increase the competitiveness of their products in the marketplace while ensuring precise control. Whether it’s a commercial or home draft beer dispenser, accurate pressure control results in a smoother pouring experience, more consistent foam management, and longer equipment life. Optimizing the selection of pressure sensors is a critical step in improving product quality for draft beer dispenser manufacturers who want to increase user satisfaction.

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.