목록

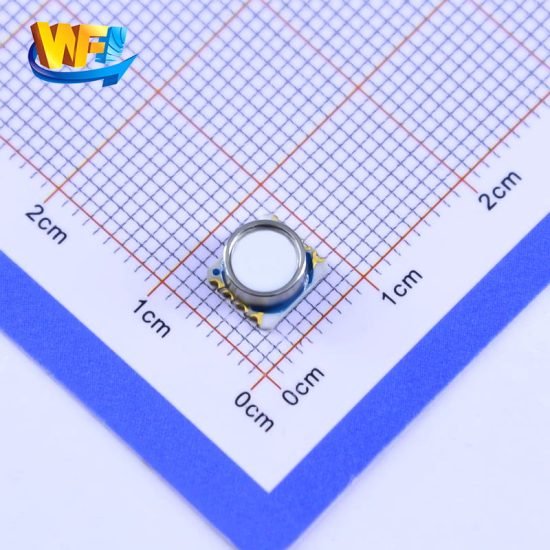

MEMS pressure sensors are redefining intelligent standards in instrumentation through microelectromechanical systems technology, achieving unprecedented measurement accuracy and response speed.

1. Intelligent Breakthrough in Pressure Range and Accuracy

Full-Range Dynamic Adaptation Technology

MEMS pressure sensors demonstrate intelligence through wide pressure range coverage from 0.1kPa to 10MPa. Dynamic adaptation enables instruments to automatically adjust measurement ranges without manual intervention, significantly improving monitoring continuity and reliability.

Relative Accuracy and Resolution Optimization

Intelligent processing of relative accuracy represents the core advantage of MEMS sensors. Built-in temperature compensation algorithms and nonlinear correction ensure stable relative accuracy under different environmental conditions.

2. Temperature Compensation and Working Environment Adaptability

Intelligent Temperature Compensation Mechanism

Temperature compensation functionality is key technology for intelligent monitoring. Built-in temperature sensing elements monitor environmental temperature changes in real-time, automatically adjusting pressure measurements through digital signal processing chips.

Working Voltage Intelligent Management

Intelligent voltage management allows MEMS sensors to adapt to different power supply environments. Wide voltage operation from 3.3V to 5V, combined with low power design, enables instruments to work normally under battery power or unstable power conditions.

3. Response Speed and Noise Control Technology

High-Speed Response and Real-Time Processing

Fast response characteristics of MEMS pressure sensors provide important foundation for intelligent monitoring. Millisecond-level response time enables instruments to track pressure changes in real-time, crucial for dynamic process monitoring.

Noise Suppression and Signal Optimization

Low noise characteristics represent important manifestation of MEMS sensor intelligence. Advanced signal processing technology controls noise levels within extremely low ranges, ensuring measurement data reliability.

4. Wide Pressure and Bidirectional Pressure Monitoring

Wide Pressure Range Intelligent Recognition

Wide pressure monitoring capability allows MEMS sensors to handle full-range pressure measurement from vacuum to high pressure. Intelligent recognition algorithms automatically judge current pressure states and adjust measurement parameters.

Positive and Negative Pressure Bidirectional Monitoring

Bidirectional monitoring of positive and negative pressure is an important feature of MEMS sensor intelligence. Sensors accurately distinguish pressure directions and provide corresponding measurement data.

5. Digital Integration and Intelligent Decision Making

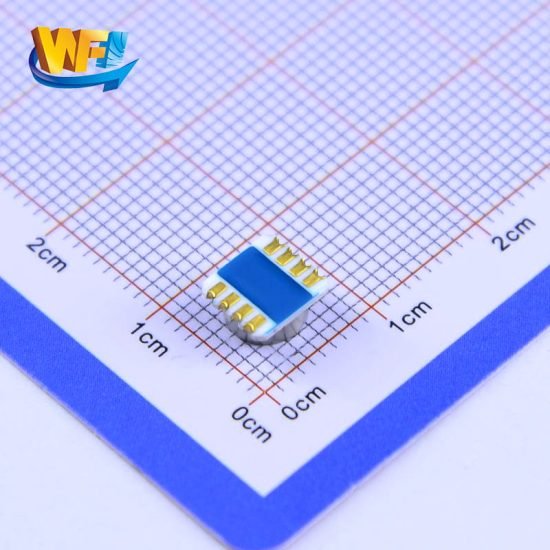

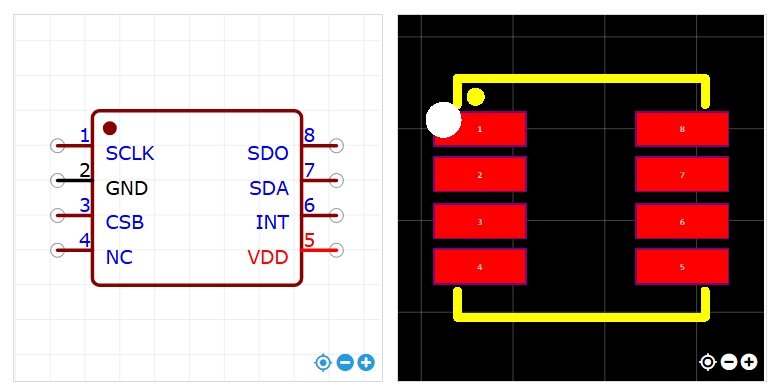

Digital Interface and System Integration

Digital interface design of MEMS pressure sensors enables easy integration into modern intelligent instrument systems. Through I2C, SPI standard communication protocols, sensors connect directly with microcontrollers.

Intelligent Algorithms and Predictive Analysis

Integrated intelligent algorithms enable MEMS sensors to provide real-time pressure data and perform trend analysis and anomaly detection. Machine learning algorithms learn normal working mode pressure characteristics.

결론

MEMS pressure sensors are driving instrumentation monitoring technology to higher levels through excellent technical characteristics and intelligent functions. These technological advances not only improve measurement accuracy and reliability but provide solid technical foundation for intelligent manufacturing in Industry 4.0 era.

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.