목록

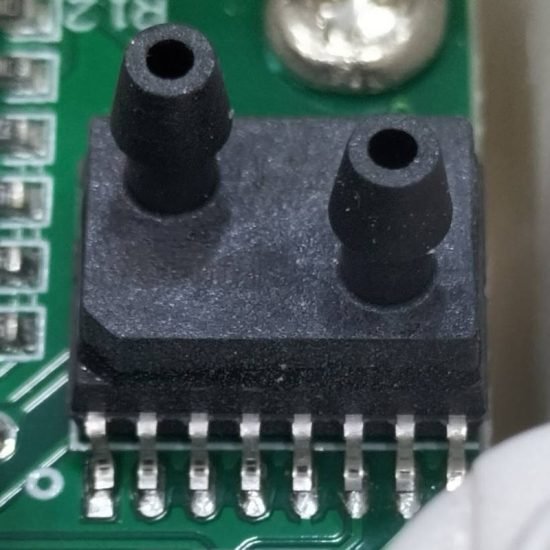

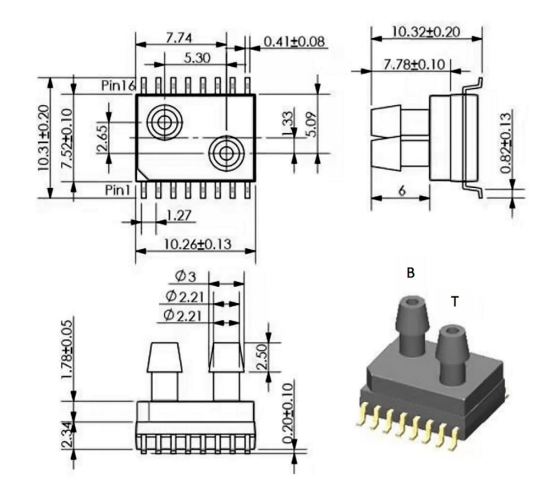

Ventilators serve as life-support devices where stable operation directly relates to patient safety. The WF200DP medical pressure sensor ensures perfect synchronization between equipment and patient breathing patterns through precise airway pressure monitoring and real-time feedback control. This MEMS-based differential pressure sensor has become an indispensable core component in modern ventilator systems due to its high accuracy, rapid response, and long-term stability.

1. Critical Role of MEMS Technology in Ventilators

압력 모니터링의 의학적 중요성

Ventilators create artificial pressure differentials to replace natural respiratory function. During normal breathing, inspiration creates negative pressure through chest expansion, while expiration generates positive pressure through alveolar elastic contraction. The WF200DP sensor precisely replicates this physiological process, ensuring accurate assessment of patient respiratory needs through real-time airway pressure monitoring.

차압 감지 원리

WF200DP employs differential pressure detection technology, simultaneously monitoring pressure differences between two ports. This design enables the sensor to eliminate environmental temperature and atmospheric pressure variations, providing more stable and accurate measurement results. Internal silicon diaphragms undergo minute deformation under pressure, converting mechanical signals to electrical signals through piezoresistive effects.

신호 처리 및 제어 피드백

Sensor-generated analog signals undergo amplification and digital conversion before transmission to the ventilator’s microcontroller unit. The MCU analyzes pressure data to assess patient respiratory status, adjusting motor speeds and valve openings to control airflow supply and discharge, achieving precise synchronization with patient breathing.

2. WF200DP Sensor Technical Advantages

고정밀 측정 기능

WF200DP sensors feature ±0.25% measurement accuracy, detecting extremely minute pressure variations. This precision level proves crucial for ventilator applications, as patient respiratory pressure changes often involve only hundreds of pascals, requiring sufficient sensor sensitivity to accurately capture these variations.

빠른 응답 특성

Sensor response times under 1 millisecond enable real-time tracking of rapid patient respiratory cycle changes. This rapid response capability ensures ventilators can promptly adjust output parameters, preventing patient discomfort or reduced treatment effectiveness due to delays.

장기 안정성 보증

Medical equipment typically requires continuous operation for thousands of hours. WF200DP sensors undergo extensive long-term stability testing, with zero-point drift and full-scale drift controlled within minimal ranges, ensuring consistent measurement accuracy during extended use periods.

3. Ventilator System Integration and Control

다중 매개 변수 협업 모니터링

Modern ventilators monitor not only pressure but also flow, temperature, humidity, and other parameters. WF200DP sensors work collaboratively with other sensors, providing comprehensive physiological parameter monitoring for treatment safety and effectiveness.

지능형 제어 알고리즘

Sensor data feeds into advanced control algorithms enabling automatic patient breathing pattern recognition and adjustment of respiratory rate, tidal volume, and positive end-expiratory pressure parameters. This intelligent control significantly reduces healthcare staff workload while improving treatment outcomes.

안전 보호 메커니즘

When sensors detect abnormal pressure values, ventilators immediately activate safety protection programs including pressure limitation, flow cutoff, and alarm notifications. These safety mechanisms effectively prevent medical accidents caused by equipment failure or operational errors.

4. Medical Application Scenarios and Performance Requirements

집중 치료실 응용 프로그램

ICU environments present complex, rapidly changing patient conditions demanding extremely high ventilator response speed and accuracy. WF200DP sensors adapt to various complex clinical situations, providing stable, reliable respiratory support for critically ill patients.

휴대용 인공 호흡기 통합

Medical equipment miniaturization trends impose higher volume and power consumption requirements on sensors. WF200DP sensors feature compact packaging design with extremely low power consumption, fully meeting portable device stringent requirements.

가정 인공 호흡기 시장

Rapid growth in home ventilator markets presents new challenges for sensor reliability and cost control. WF200DP sensors achieve effective cost control through scaled production and process optimization while maintaining high performance, enabling high-quality respiratory therapy equipment accessibility to more households.

5. Quality Assurance and Certification Standards

의료 기기 인증

WF200DP sensors comply with ISO 13485 medical device quality management system requirements and pass FDA, CE, and other international authoritative certifications. Strict quality control processes ensure every sensor meets demanding medical application requirements.

생체 적합성 테스트

Sensor materials undergo rigorous biocompatibility testing, ensuring no harmful reactions during human contact. Housing materials utilize medical-grade polymers with excellent corrosion resistance and chemical stability.

환경 적응성 검증

Medical environments demand exceptional equipment environmental adaptability. WF200DP sensors undergo comprehensive testing including temperature cycling, humidity, vibration, and electromagnetic compatibility, ensuring stable operation in various complex medical environments.

결론

WF200DP medical pressure sensors provide accurate, stable, reliable pressure monitoring for ventilators through advanced MEMS technology. High-precision measurement capability, rapid response characteristics, and long-term stability ensure ventilators accurately respond to patient respiratory needs, providing safe, effective respiratory support.

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.