- 에 의해 WF센서

Pressure difference in HVAC systems directly affects airflow balancing, filter health monitoring and overall energy efficiency. A reliable, interference-resistant differential pressure measurement can spot trouble early, cut running costs and extend equipment life. Modern digital differential sensors bundle the sensing element, signal conditioning and digital output into a compact unit, giving you high-precision, traceable data that’s easy to integrate and monitor remotely.

목록

1. The role of differential pressure sensors in HVAC control

Differential pressure sensors continuously monitor pressure differences across ducts, filters and return air streams, and they provide the core diagnostic signal HVAC controllers rely on. In large buildings or precision environments, pressure imbalances lead to uneven air delivery, mismatched heating/cooling loads and, frankly, poor comfort and wasted energy. In practice, sensors must deliver stable readings even under dynamic loads and noisy conditions, producing data fine-grained enough for control algorithms — think VAV adjustments and filter-clog alerts. When choosing a sensor, don’t stop at range and resolution: long-term zero drift, temperature-related errors and communication robustness all determine whether a reading is actionable for control systems.

Why precise pressure-differential measurement matters for system

HVAC systems depend on continuous, accurate pressure feedback to stay balanced. When differential readings wander, controllers can keep fans running harder than necessary or trigger pointless maintenance calls. Accurate sensors let controllers use smaller deadbands and faster responses to tweak fan speeds or valve positions, saving energy and improving comfort. And here’s the clincher: good data supports trend analysis, so you can spot clogged filters or duct leaks early and avoid surprise failures.

2. Key points in digital sensor design

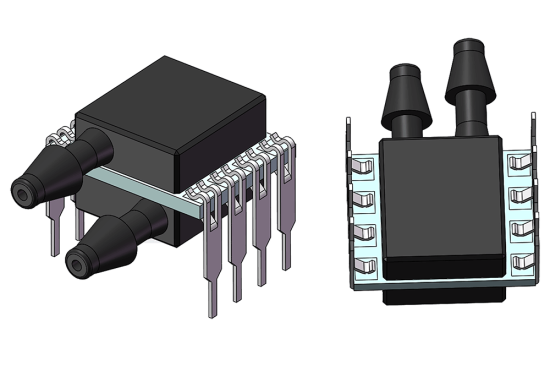

Modern differential sensors combine the sensing element and a signal-conditioning chip to carry out digital compensation for non-linearity, sensitivity shifts and offset. SOP8 packaging is a common industrial choice; the anti-pull barb lets you attach tubing securely, preventing accidental disconnection. Built-in conditioning circuitry amplifies and linearises the microvolt-level sensor output and converts it into a digital stream, which noticeably boosts immunity to electrical noise and enhances repeatability. From an engineering standpoint, integrated digital design reduces the need for external amplifiers and filters, speeding up integration and trimming system complexity.

SOP8 packaging and barb fitting — engineering considerations

SOP8 boards up neatly on a PCB, and the internal barb fitting connects to hoses without extra fixtures — a big practical win during site installation. The barb’s anti-pull profile helps in vibration-heavy environments and cuts field failure rates. For building automation projects, ease of replacement and straightforward board-mounting save time and procurement headaches. That said, consider thermal effects: packaging affects heat flow and temperature uniformity, so you need to ensure the onboard temperature sensor reflects real operating conditions for accurate compensation.

3. Paths to achieve accuracy and stability

High accuracy isn’t just about a great sensing element; it’s about the whole chain — notably a 24-bit ADC plus an onboard temperature sensor and a robust digital calibration routine. A 24-bit ADC gives high resolution across a wide dynamic range; paired with digital compensation algorithms for non-linearity and temperature drift, it yields high-confidence data you can feed straight into control loops. These sensors are factory-calibrated so they deliver stable pressure and temperature readings out of the box — essential for applications demanding long-term stability such as VAV control, flow metering and energy analytics.

24-bit ADC and onboard temperature sensor

An onboard temperature sensor allows the device to correct for thermal drift in real time, using lookup tables or polynomial fits embedded in the chip. Factory calibration captures the sensor’s response at multiple temperatures and pressures, storing correction parameters in on-chip memory. That means, in the field, you simply read the corrected digital output — no extra maths on the controller. When assessing long-term stability, focus on post-temperature-cycle drift, zero-point stability over months or years, and consistent response under pulsating airflow.

4. System integration and communication schemes

Solid digital interfaces like I²C are key for modern HVAC integration. Digital output slashes susceptibility to analogue noise, extends effective wiring lengths, and plugs straight into microcontrollers and building management systems. I²C’s bus nature makes multi-point pressure monitoring cost-effective. The sensors’ supply range (2.5–5.5 V) and low-power design mean they’re easy to drop into battery-backed or low-energy control nodes.

Tips for low-power and field reliability

In practice you balance sampling rate, filtering and power use. Higher sample rates give faster responses but increase noise and energy draw; event-driven sampling or software filtering helps find a middle ground. Field reliability also ties back to conditions: these sensors are for non-corrosive gases, and the low-pressure side can withstand up to 500 kPa overpressure — useful to know when designing for robustness. Add overpressure protection, mechanical buffering and careful placement to avoid thermal or liquid exposure that could skew readings or damage the device.

5. Typical application scenarios and spec matching

Differential sensors in HVAC are used for estimating airflow, monitoring filter clogging, feeding pressure-controlled valves and closing the loop in VAV systems. Pick a sensor whose range matches the job — for example, 0.5 kPa ranges for small duct differentials, bigger ranges for fan inlet/outlet measures. Digital differential sensors reduce installation and calibration time and give you live, compensated data for energy optimisation. Typical measurement ranges span from −100 kPa up to 200 kPa, and the low-pressure side’s 500 kPa overpressure capability broadens applicability across conditions.

From diagnostics to maintenance — how sensor data drives HVAC decisions

High-precision sensor data can be modelled over time to support predictive maintenance. By watching pressure trends you can detect filter wear, duct leakage or falling fan efficiency and act before the issue worsens. That saves money by cutting unnecessary maintenance and improves uptime. Engineers should include data logging and remote readout in system designs to make operation and maintenance straightforward.

결론

Differential pressure sensors are a foundational component for improving HVAC efficiency and reliability. Digital designs — featuring 24-bit ADCs, onboard temperature sensing and I²C outputs — and the practical benefits of SOP8 packaging make these sensors straightforward to integrate while maintaining precision under real-world conditions. Correct selection depends on range, resolution, temperature drift behaviour and overpressure tolerance (note the 500 kPa figure for the low side). When you tie sensor outputs into control and maintenance loops, building operators get better energy control and lower operational risk. During deployment, check supply range, sealing and long-term stability after temperature cycling.

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.

Excellent post. I was checking constantly this blog and I am

impressed! Very useful info specially the last part 🙂 I care for such information a lot.

I was seeking this certain information for a very long time.

Thank you and best of luck.

It’s awesome to go to see this website and reading the views of all mates on the topic of this post, while I

am also keen of getting knowledge.