목록

Xiaomi air pumps utilize analog pressure sensors based on advanced MEMS technology, achieving high-precision pressure detection through silicon-silicon bonded structures. These sensors feature 0-700kPa detection range with internal trimming technology and optimized signal processing algorithms.

1. Core Technology Principles of MEMS Piezoresistive Sensors

실리콘-실리콘 결합 구조의 기술적 이점

MEMS piezoresistive pressure sensors employ silicon-silicon direct bonding technology to construct sensing structures, forming highly stable stress membranes and sealed cavities. The single-crystal silicon structure ensures excellent mechanical strength and thermal stability, while bonding processes guarantee internal vacuum environments, eliminating temperature drift and long-term stability issues.

압전성 효과의 물리적 메커니즘

Piezoresistive sensors operate based on silicon material’s piezoresistive effect. When mechanical stress is applied, silicon lattice structure undergoes micro-deformation, causing carrier mobility changes and resistance value variations. Xiaomi air pump sensors integrate four high-precision piezoresistive elements in maximum stress regions, forming Wheatstone bridge structures.

2. Manufacturing Process and Quality Control of Analog Sensors

정밀 제조 워크 플로

Sensor chips employ standard MEMS manufacturing processes including silicon wafer cleaning, oxide layer growth, photolithographic patterning, ion implantation doping, and high-temperature annealing. Critical silicon-silicon bonding processes occur at 1000°C in vacuum environments, ensuring atomic-level interface bonding. Precision thinning processes control silicon membrane thickness within 15±2μm ranges.

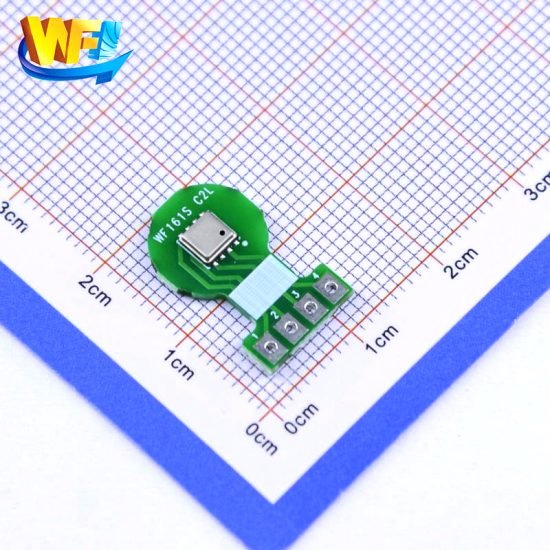

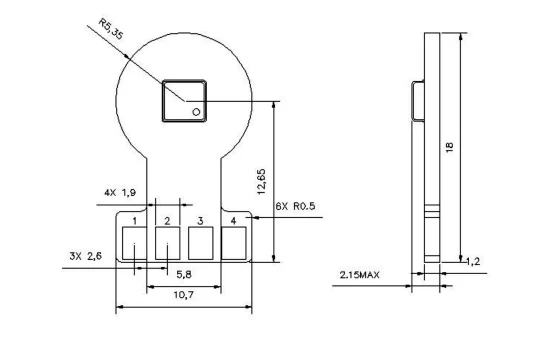

LGA 포장 기술 구현

Sensors utilize PCB plus metal shell LGA packaging forms. Metal housings provide electromagnetic shielding and mechanical protection, while PCB substrates enable electrical connections and signal conditioning. Four solder pins correspond to positive/negative power supplies, signal output, and grounding, simplifying customer mounting processes.

3. Technical Implementation of Precision Measurement Performance

내부 트리밍 기술의 핵심 역할

Xiaomi air pump sensors achieve precise calibration at four pressure points through internal trimming technology, including 0kPa, 200kPa, 500kPa, and 700kPa. Trimming processes use laser micro-adjustment resistor networks, precisely adjusting sensor zero-point offset and full-scale output, controlling nonlinear errors within 0.5%.

온도 보상 및 드리프트 억제

Sensors integrate temperature compensation circuits, employing polynomial temperature compensation algorithms to eliminate temperature effects on output signals. Through multi-point calibration across -20°C to +60°C ranges, temperature compensation coefficient tables are established, achieving accurate measurements across full temperature ranges.

4. Signal Processing and Algorithm Optimization

아날로그 신호 샘플링 알고리즘

Air pump solutions employ high-precision ADCs for analog signal sampling, with sampling frequencies set at 2kHz, ensuring accurate capture of rapid pressure changes. Signal processing algorithms include digital filtering, nonlinear correction, and anomaly detection, effectively filtering environmental noise and transient interference.

반응 방지 설계 메커니즘

Sensors employ hydrophobic coatings and sealed structural designs, effectively preventing condensation formation in high-humidity environments. Metal housing thermal conduction characteristics ensure sensor temperatures remain consistent with environmental temperatures, avoiding condensation phenomena caused by temperature differences.

5. Industry Applications and Performance Comparison Analysis

시장 경쟁 업체의 기술적 격차

Traditional air pumps commonly suffer from measurement inaccuracy issues, primarily due to sensor manufacturing errors, lack of effective calibration mechanisms, and inadequate signal processing algorithms. Xiaomi air pumps improve measurement errors from traditional products’ ±5% to ±1% through high-quality MEMS sensors and advanced signal processing technology.

실제 응용 프로그램 성능 검증

In practical use, Xiaomi air pump analog pressure sensors demonstrate excellent repeatability and stability. After 1000 inflation-deflation cycle tests, sensor output repeatability errors remain below 0.2%, with long-term stability superior to 0.5%/year. This high-precision performance eliminates need for repeated tire pressure checks.

결론

Analog sensor technology application significantly enhances Xiaomi air pump precision measurement performance. Through silicon-silicon bonded MEMS processes, precise internal trimming technology, optimized signal processing algorithms, and anti-condensation designs, ±1% high-precision measurement is achieved, solving traditional air pump measurement inaccuracy industry pain points.

위의 소개는 압력 센서 기술 적용의 표면적인 부분에 불과합니다. 우리는 다양한 제품에 사용되는 다양한 유형의 센서 요소, 작동 방식, 장점과 단점을 계속해서 탐구할 것입니다. 여기에서 논의된 내용에 대해 더 자세히 알아보려면 이 가이드 뒷부분의 관련 콘텐츠를 확인하세요. 시간이 촉박한 경우 여기를 클릭하여 이 가이드의 세부정보를 다운로드할 수도 있습니다. 공기 압력 센서 제품 PDF 데이터.

다른 센서 기술에 대한 자세한 내용은 다음을 참조하십시오. 센서 페이지를 방문하십시오.