Infusion pumps are key devices used in modern medical equipment for precise control of drug or fluid delivery. Especially in therapeutic areas where high flow accuracy is required (e.g. anesthesia, nutritional support and chemotherapy), the stability and reliability of infusion pumps are crucial. And 공기 압력 센서 play a vital role in this process, especially in monitoring pressure changes, bubble detection and infusion rate control to ensure the safety of the treatment process.

이해를 시작합시다!

목록

주입 펌프에서 공기압 센서의 중심 역할

주입 라인 압력 모니터링

Air pressure sensors are able to monitor pressure changes within the infusion line in real time, recognizing blockages (e.g., clogged needles, bent lines) or leaks (e.g., ruptured infusion tubes) in a timely manner. By setting the appropriate pressure threshold, the sensor can trigger an alarm and automatically pause the infusion to avoid patient harm or overdose.

기포 감지 버블

Can occur during infusion, especially when the infusion bag is emptied and air can enter the line. By detecting pressure fluctuations, the 공기 압력 센서 is able to accurately recognize the presence of air bubbles, preventing the risk of gas embolism and ensuring the safety of drug infusion.

주입 속도 컨트롤비

Incorporating flow rate feedback, the air pressure sensor is able to dynamically adjust the pump drive motor to compensate for flow rate deviations due to changes in patient position or fluctuations in venous pressure. This ensures stability of the infusion rate, especially important when infusing highly viscous fluids such as parenteral nutritional solutions.

센서 유형 및 선택

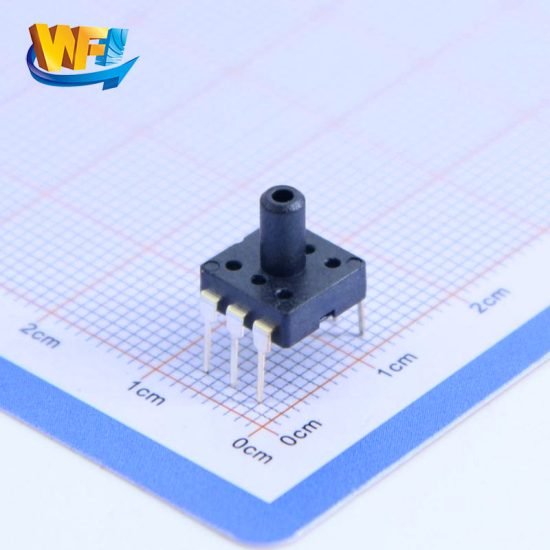

압전성 센서

Piezoresistive sensors utilize MEMS technology to measure pressure through changes in resistance caused by deformation of a silicon diaphragm. Its advantages are high sensitivity and miniaturization, making it suitable for integration into infusion pump modules. However, it requires temperature compensation to ensure its accuracy.

용량 성 센서

Capacitive sensors sense pressure changes by detecting changes in the distance between the pole plates. This type of sensor is highly resistant to electromagnetic interference and is suitable for scenarios that require high accuracy (e.g., neonatal infusion). However, they are more costly and suitable for use in high-end medical devices.

광섬유 압력 센서

Fiber optic pressure sensors have no risk of electrical signal interference and are particularly suitable for use in strong electromagnetic environments, such as MRI examination environments. However, it has a higher system complexity and is usually used in specialized medical scenarios.

선택 키 매개 변수

광섬유 압력 센서

- Range: Typically required to cover a range from -50 mmHg (negative pressure detection) to +600 mmHg (high pressure blockage scenario).

- 정확성: within ±1% FS (full scale error) to ensure that small pressure changes are captured.

- Response time: Less than 10 ms, enabling fast response to instantaneous changes in pressure such as when a catheter is dislodged.

시스템 설계 포인트

중복 안전 설계

To increase the reliability of the system, dual sensors can be used for cross-verification. For example, the primary sensor monitors the infusion line pressure and the secondary sensor detects the pump head mechanical pressure. This avoids a single point of failure and reduces the risk of false alarms and missed alarms.

신호 처리 알고리즘

Dynamic Baseline Calibration: Automatically corrects for zero point errors caused by ambient temperature or long-term drift.

Noise Filtering: Digital filtering techniques (e.g. moving average, wavelet transform) are used to eliminate signal interference from patient motion or pump motor vibration.

의료 준수

공기 압력 센서 must comply with medical standards such as IEC 60601-1 (Electrical Safety for Medical Use) and ISO 80369 (False Connection Prevention for Infusion Systems). In addition, the sensor material should be able to withstand common medical sterilization methods such as ethylene oxide (EtO) sterilization or gamma irradiation.

일반적인 응용 프로그램 예

막힘 경보 시스템

When the pressure in the infusion line consistently exceeds a set threshold (e.g., 300 mmHg), the system determines that there is a blockage and immediately stops the pump for an alarm. The algorithm needs to distinguish between brief pressure spikes (e.g., patient’s cough) and actual blockage to avoid false alarms.

적응 형 주입 제어

During the infusion of highly viscous drugs, the data from the sensors are fed back to the PID controller, which automatically adjusts the stepper motor torque of the pump to ensure a constant infusion rate.

주입 완료 경고

When the infusion bag is close to empty, the sensor detects the increase of negative pressure in the pipeline, and the system sends out an early warning to help nurses deal with the situation in time and reduce the operation delay.

문제와 솔루션

드리프트 문제

Barometric pressure sensors may experience zero drift during long-term use. To solve this problem, a self-test program can be designed, such as automatically performing a zero calibration every day, to ensure that the sensor works stably for a long period of time.

교차 감염 위험

The sensor and the infusion line should be kept isolated to avoid direct contact with the drug solution. Isolation can be achieved through a breathable membrane to prevent cross-contamination.

비용 관리

In low-end devices, analog output sensors coupled with MCU-integrated ADC solutions can be designed to replace digital sensors to some extent, reducing costs while maintaining basic performance.

결론

The application of air pressure sensors in medical syringe infusion pumps plays an important safety role in ensuring pressure stability and safety during drug or liquid delivery. As medical technology advances, the integration of barometric pressure sensors will become smarter, and more sensors with multi-parameter fusion (e.g., pressure, flow, temperature) combined with AI-driven anomalous pattern recognition technology are likely to emerge in the future. Designers will need to find a balance between accuracy, reliability and cost, and ensure that the sensors meet stringent medical regulatory requirements to enhance the performance and safety of infusion pumps.