Каталог

MEMS pressure sensor technology is redefining technical standards in the e-cigarette industry. Traditional single-sensor designs have significant flaws, with environmental pressure fluctuations and geographical variations severely impacting device performance. Next-generation MEMS pressure sensors like the WF183DE-1BAR implement dual-sensor architecture with environmental compensation, effectively eliminating false triggers. This innovation enhances reliability and establishes a solid foundation for industry technological advancement.

Technical Limitations of Traditional Single-Sensor Architecture

Severe Environmental Adaptability Issues

Traditional e-cigarettes use single pressure sensors to control chamber pressure by monitoring airflow changes to adjust heater power. While seemingly simple, this approach reveals serious technical flaws in practice. Environmental atmospheric pressure fluctuates continuously due to weather changes, and geographical differences cause baseline pressure variations. The most problematic scenario occurs when users ride high-speed elevators, with vertical speeds reaching 20 meters per second, causing instant pressure changes that trigger false activation. These limitations directly impact market applicability and user experience.

Root Cause Analysis of Reliability Issues

The fundamental problem with single-sensor architecture is the lack of environmental baseline compensation. Absolute pressure sensors output absolute pressure values without distinguishing environmental changes from genuine user inhalation. When external pressure factors interfere, sensors cannot accurately identify valid signals, causing system response errors. This design flaw becomes particularly evident under complex environmental conditions, severely constraining e-cigarette product development and market adoption.

MEMS Dual-Sensor Compensation Technology Innovation

WF183DE-1BAR Technical Architecture Advantages

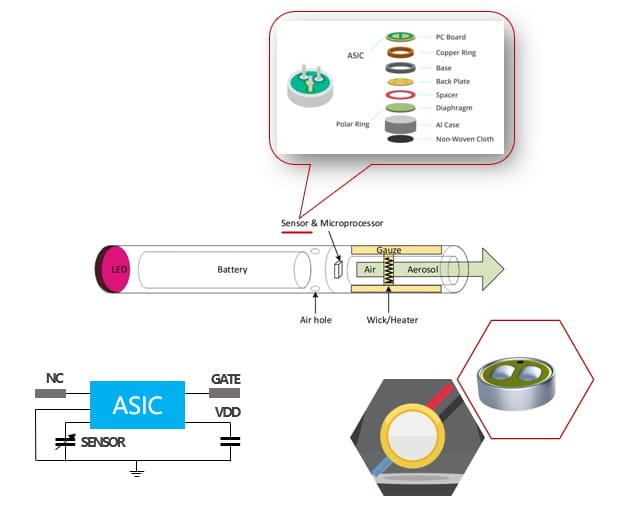

The WF183DE-1BAR employs innovative dual-sensor compensation architecture, using one reference sensor for real-time environmental pressure monitoring and another for airflow channel pressure detection. Real-time comparison of both sensor data precisely identifies genuine user inhalation while completely eliminating environmental interference. This approach fundamentally resolves traditional single-sensor limitations, significantly improving system reliability and environmental adaptability. The 8-pin LGA package offers compact dimensions suitable for integration into space-constrained e-cigarette devices.

In-depth Technical Implementation Analysis

Dual-sensor compensation technology relies on differential measurement principles. The reference sensor continuously monitors environmental baseline pressure while the working sensor detects airflow channel pressure. The system calculates pressure differentials through algorithms, activating the heater only when differentials exceed preset thresholds and change patterns match inhalation characteristics. This intelligent recognition mechanism effectively prevents environment-induced false triggers, ensuring device activation only during genuine user inhalation.

Package Engineering and Integrated Design

LGA Package Technology Benefits

The WF183DE-1BAR utilizes 8-pin LGA (Land Grid Array) packaging, offering superior thermal conductivity and mechanical stability compared to traditional QFN packages. LGA’s planar contact design reduces soldering stress, enhancing long-term reliability. The precision-machined pressure inlet on the sensor top ensures accurate pressure transmission and sealing integrity. This packaging design particularly suits demanding applications in small electronic devices like e-cigarettes.

Engineering Value of Miniaturization

Modern e-cigarettes impose strict requirements on component size, weight, and power consumption. The WF183DE-1BAR’s compact design meets these demanding specifications with optimized dimensions and microwatt-level power consumption. Miniaturization saves valuable internal space while reducing overall weight, improving user grip comfort. This design philosophy demonstrates MEMS technology’s unique value in consumer electronics.

Technology-Driven Industry Transformation

From Passive Response to Active Control

MEMS pressure sensor technology transforms e-cigarettes from simple switch control to intelligent active management systems. Sensors not only accurately detect user inhalation but also dynamically adjust heating power based on inhalation intensity and frequency, delivering personalized user experiences. This technological upgrade shifts traditional e-cigarette operation from passive response to intelligent active control, providing technical foundations for product differentiation.

Quality Standards and Reliability Enhancement

Dual-sensor compensation technology significantly elevates e-cigarette quality standards. Dramatically reduced false trigger rates directly improve user experience while reducing complaints and after-sales issues. High-reliability sensor technology strengthens manufacturers’ competitive advantages, driving industry-wide premium development. This progress enhances individual product performance while promoting entire supply chain technological advancement.

Market Applications and Technical Prospects

Comprehensive Market Coverage Solutions

WFsensors leverages MEMS platform advantages to develop complete product lines covering high, mid, and low-end markets. Beyond pressure sensors, the portfolio includes flow meters and flow switches, providing flexible technical options for different e-cigarette positioning. This comprehensive coverage capability helps manufacturers establish technical advantages across market segments while elevating industry-wide technical standards.

Future Technology Development Directions

MEMS pressure sensor technology continues evolving toward higher integration, lower power consumption, and faster response times. Integration with AI algorithms will further enhance personalized user experiences. As IoT technology advances, intelligent e-cigarette products will feature enhanced connectivity and interaction capabilities, with MEMS sensor technology playing central roles in this development process.

Қорытынды

MEMS pressure sensor technology revolutionarily resolves traditional e-cigarette technical pain points through dual-sensor compensation architecture, fundamentally improving reliability and environmental adaptability. Advanced sensors like the WF183DE-1BAR represent cutting-edge industry achievements, providing strong support for e-cigarette industry technological advancement. This innovation enhances user experience while driving industry-wide intelligent and premium development, establishing solid technical foundations for sustainable e-cigarette industry growth.

Жоғарыда келтірілген кіріспе тек қысым сенсорының технологиясының қолданбаларының бетін көрсетеді. Біз әртүрлі өнімдерде қолданылатын сенсорлық элементтердің әр түрлі түрлерін, олардың қалай жұмыс істейтінін және олардың артықшылықтары мен кемшіліктерін зерттеуді жалғастырамыз. Егер сіз осы жерде талқыланғаныңыз туралы толығырақ болғыңыз келсе, осы нұсқаулықта тиісті мазмұнды кейінірек тексере аласыз. Егер сіз уақытылы бассаңыз, осы нұсқаулықтардың мәліметтерін жүктеу үшін мына жерді басуға болады Ауа қысымы сенсоры PDF деректері.

Басқа сенсорлық технологиялар туралы қосымша ақпарат алу үшін өтінемін Біздің сенсорлар парағын кіріңіз.