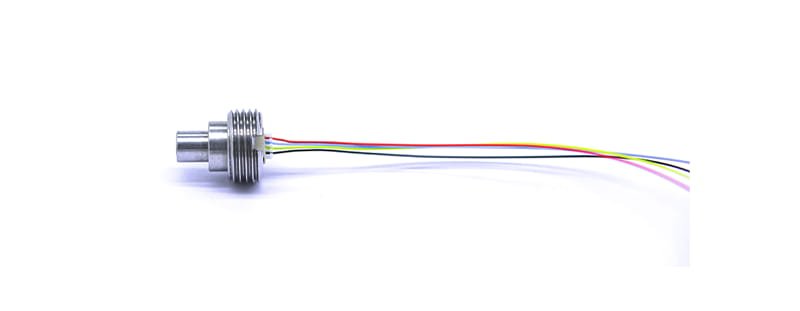

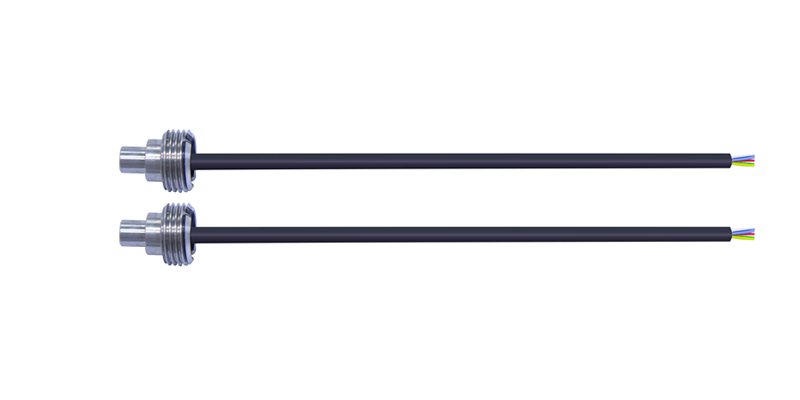

Media-Isolated Pressure Sensor Delivering Stable Output in Water-Meter Hydraulics

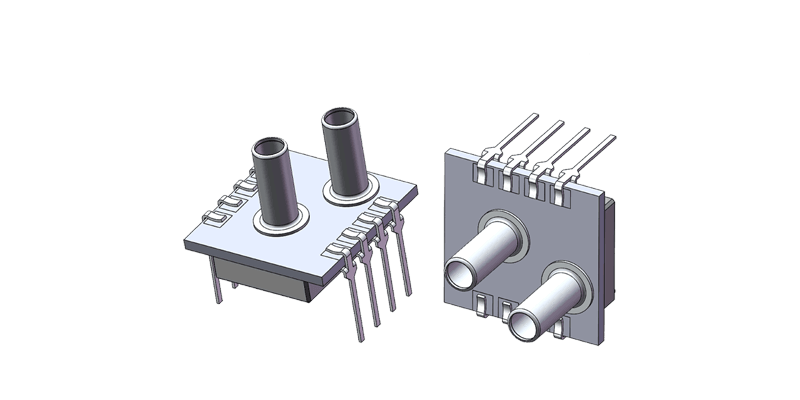

Media-isolated pressure sensors use a metal diaphragm and oil-filled cavity to separate the silicon strain gauge from the measured fluid. By combining proper materials, diaphragm geometry, signal conditioning (amplified ratiometric or digital I2C/SPI outputs), and temperature compensation, these sensors achieve long-term, linear, and repeatable pressure output in water-meter hydraulic environments.