カタログ

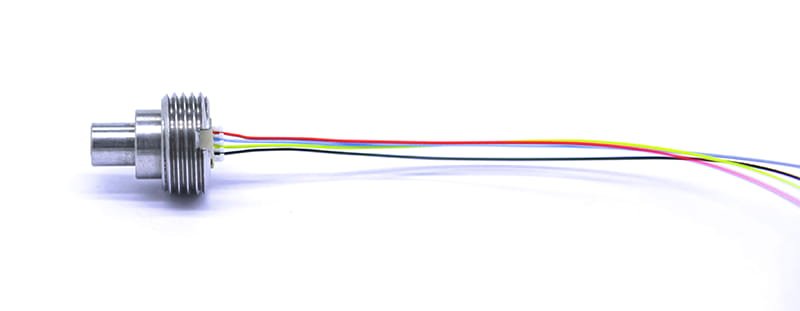

When facing corrosive fluids, high-temperature steam, and complex industrial wastewater, sensors must balance durability and measurement accuracy. Environmental pressure sensors meet requirements across pneumatic control to high-pressure hydraulics by using 17-4PH or 316L stainless-steel metal diaphragms, a weld-free pressure chamber, and multi-mode outputs. The following sections detail key technologies and engineering considerations.

1. Structural and Material Advantages

Metal diaphragm and integrated machining ensure long life and media safety

Environmental pressure sensors use metal diaphragms machined integrally from 17-4PH or 316L stainless steel. The pressure cavity has no weld seams and no organic materials in contact with the medium. This design greatly reduces failure risks caused by weld fatigue, interface leakage, or degradation of organic materials. In corrosive media or fluids containing solid particles, the metal integrated structure delivers stable mechanical response and a longer service life. It is also easier to clean and maintain, meeting strict industrial lifetime requirements.

Supplementary paragraph (concise): The integrated metal design supports high-pressure sealing and mechanical strength, prevents contact between sensitive elements and organic adhesives, increases reliability in chemically aggressive or abrasive fluids, and lowers long-term replacement and downtime costs.

2. Wide Pressure Measurement Capability

Range up to 15kpsi accommodates scenarios from pneumatics to high-pressure

This sensor family supports ranges up to 15kpsi and offers several standard intermediate ranges, allowing flexible response from low-pressure pneumatic control to high-pressure hydraulic systems. The wide-range design reduces model proliferation and improves inventory and procurement efficiency. A standardized mechanical interface and consistent range calibration ensure linearity and repeatability across different pressure levels, enabling engineering teams to select and deploy quickly.

Supplementary paragraph (concise): Range versatility lets one sensor model serve multiple production lines or devices, reducing spare-part diversity and simplifying maintenance.

3. Output Interfaces and System Compatibility

Analog and digital dual outputs for direct compatibility with PLCs and embedded controllers

Environmental pressure sensors provide various analog outputs (such as 0–5V, 1–5V, 4–20mA) and support digital buses (I2C, SPI). Digital outputs can deliver up to 14-bit pressure resolution and 11-bit temperature data, facilitating system-level compensation and recording. The dual-output approach satisfies traditional PLC/DAS direct-connection needs while supporting modern embedded controllers or gateways for remote data collection and edge computing. This significantly reduces integration complexity and secondary development work.

Supplementary paragraph (concise): Standardized interfaces cut adapter circuitry, shorten integration time, and reduce errors introduced by protocol conversions.

4. Thermal Stability and Temperature Compensation

Built-in high-precision temperature compensation preserves zero and span stability

Temperature swings cause sensor drift and affect long-term measurement consistency. This sensor series embeds high-precision temperature compensation algorithms that combine device-level and system-level correction to suppress zero and sensitivity changes caused by temperature. The combination of thermal design and software compensation ensures stable outputs across a wide temperature range. This preserves measurement comparability over long-term operation and supports trend analysis and fault detection.

Supplementary paragraph (concise): Stable thermal performance reduces site calibration frequency and increases the reliability of data used in control loops.

5. Industrial Applications and Implementation Considerations

Deployment essentials and reliable integration strategies for automation and energy management

Environmental pressure sensors are suitable for hydraulic and pneumatic systems, pumps and compressors, pipeline pressure monitoring, and medical gas monitoring. During engineering deployment, attention should be paid to mechanical interface matching, how piping layout affects response, and signal grounding and shielding to reduce electromagnetic interference. Choosing the appropriate output type (analog or digital) can lower on-site modification work; proper sealing and protection design ensures long-term stable operation in high-humidity or corrosive environments.

Supplementary paragraph (concise): From selection to commissioning, technical teams should prioritize sensor compatibility and long-term maintainability so that measurement data can be directly used in control loops and operations decisions.

結論

Environmental pressure sensors combine integrated metal construction, wide measurement ranges, dual outputs, and high-precision temperature compensation to deliver stable and reliable pressure measurements under corrosive fluids, high-temperature steam, and complex industrial wastewater. For engineers and technical decision-makers, proper selection and standardized integration can significantly reduce system integration costs and improve operational reliability, enabling precise control of industrial and automation systems.

上記の紹介は、圧力センサー技術のアプリケーションの表面をなぞっただけです。私たちは、さまざまな製品で使用されているさまざまなタイプのセンサー素子、それらがどのように機能するか、そしてそれらの長所と短所を引き続き調査していきます。ここで説明する内容についてさらに詳しく知りたい場合は、このガイドの後半にある関連コンテンツをご覧ください。時間がない場合は、ここをクリックしてこのガイドの詳細をダウンロードすることもできます。 空気圧センサー製品PDFデータ。

他のセンサー技術の詳細については、こちらをご覧ください。 センサーページにアクセスしてください。